Thin-walled cylinder girth welding device

A thin-walled cylinder and girth welding technology, which is used in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of uneven force on the cylinder, difficult to control the amount of misalignment and deformation, and inability to guarantee the positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

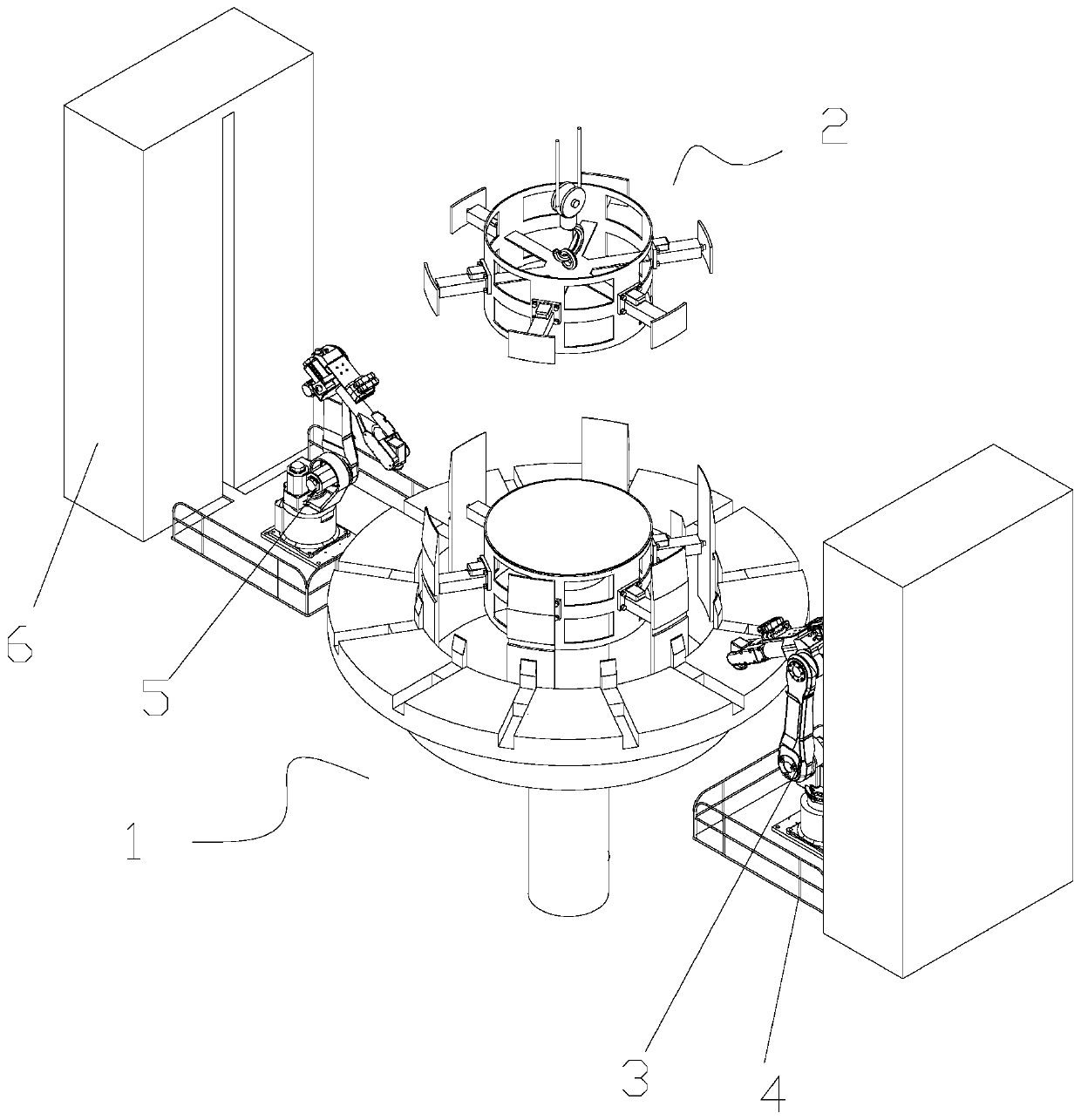

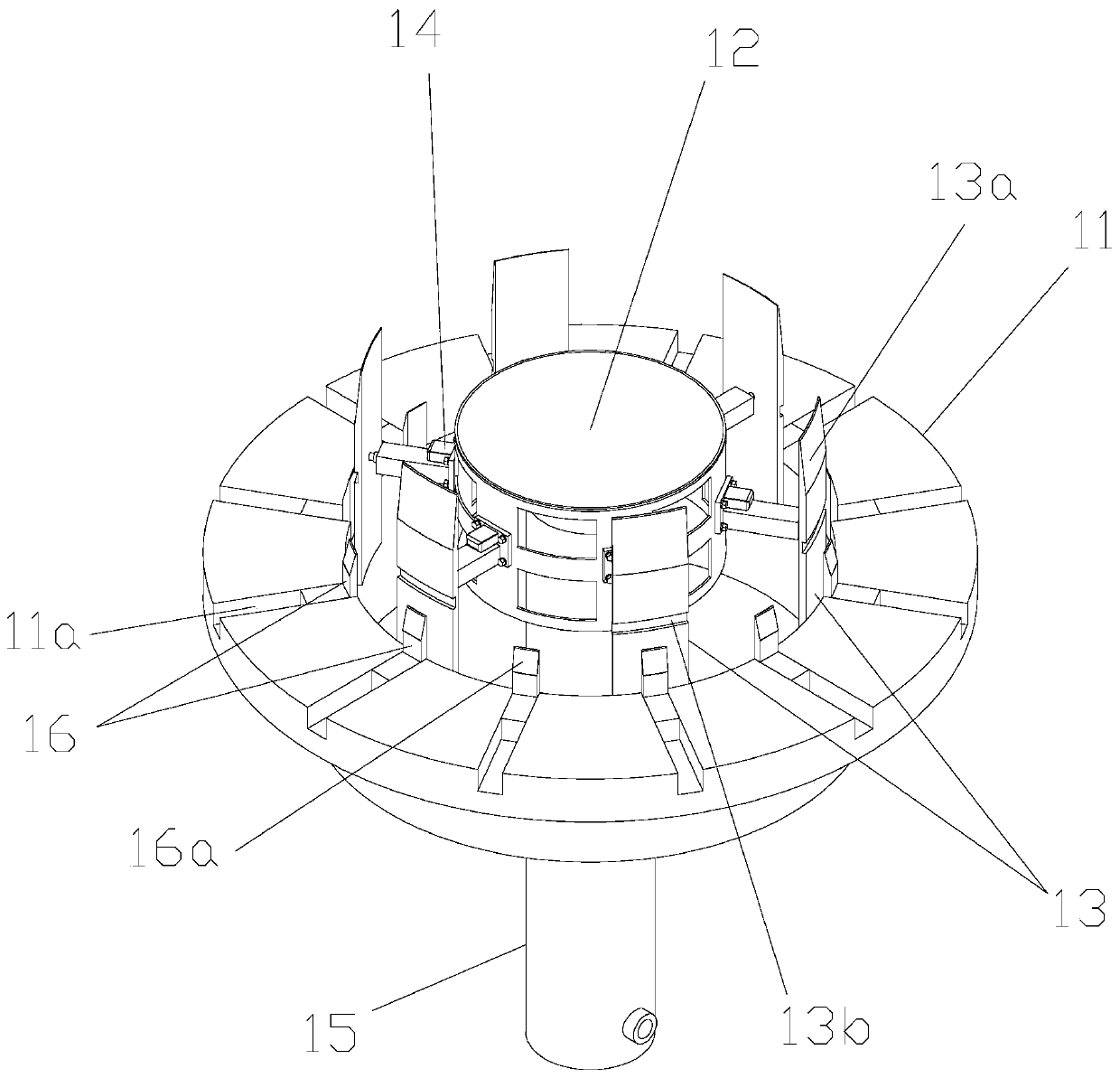

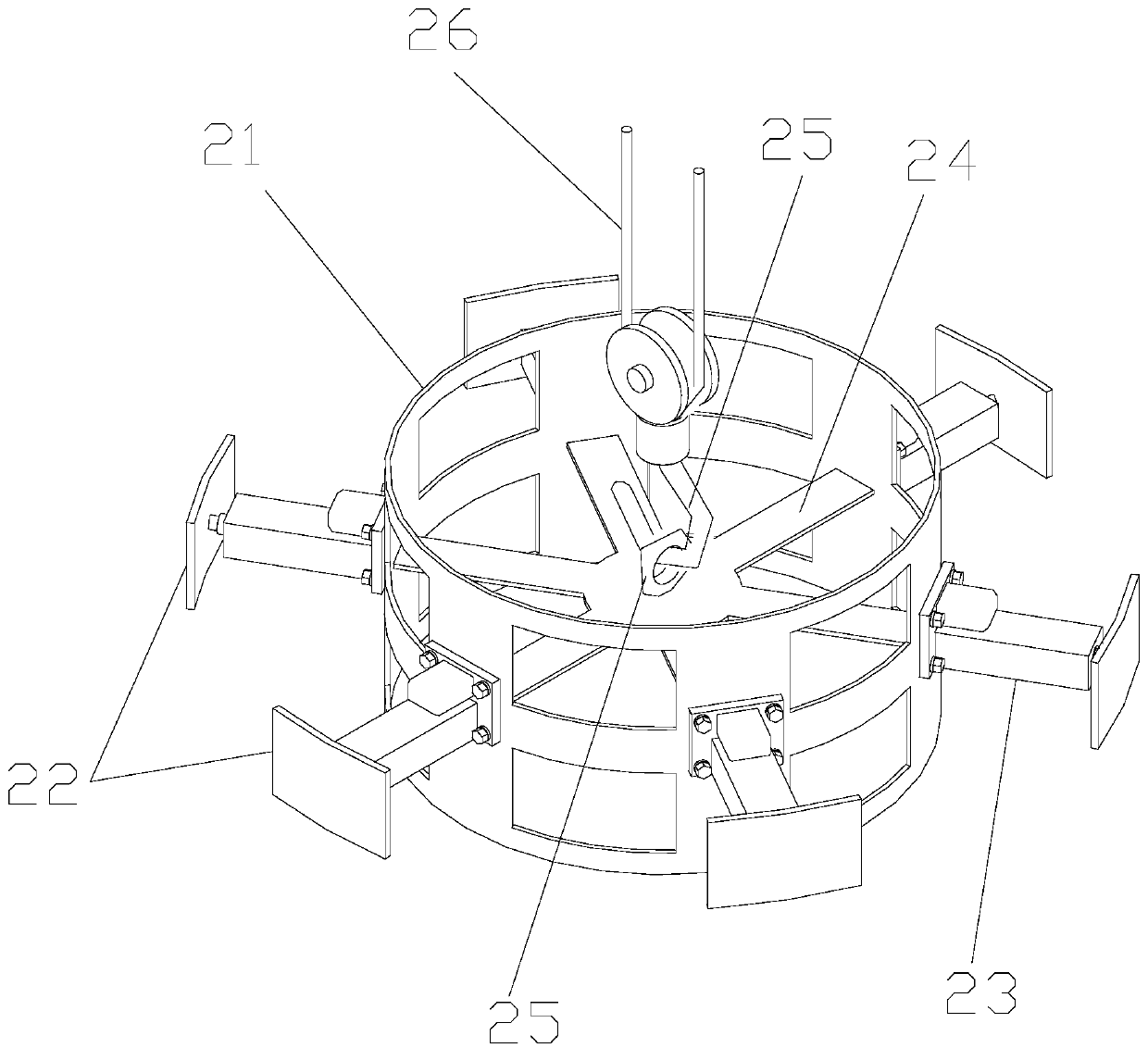

[0023] Such as Figure 1 to Figure 3 Shown: a thin-walled cylindrical girth welding device in this embodiment, including an inner support tool 1 for positioning and tightening the tube joint and an inner support lifter 2 for hoisting the tube joint to the inner support tool 1; the device It also includes an arc welding machine 3 for welding the circular seam of the upper and lower cylinder joints, and the arc welding machine is positioned on the lifting platform I4 that can be lifted vertically; at the same time, the device also includes an arc welding machine for grinding the circular seam The grinding machine 5, the arc welding machine 3 is positioned on the lifting table II6 that can be lifted vertically; the arc welding machine 3 and the grinding machine 5 are preferably the existing mechanical arm structure, so that the efficiency of the ring welding operation is greatly improved ; The arc welding machine 3 and the grinding machine 5 are respectively located on the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com