Mixing stirring device for scouring and abrading resisting concrete for hydraulic engineering

A water conservancy project, mixing and stirring technology, applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of a large amount of waste, high power consumption, etc., to reduce waste, reduce the amount of mixing, control a single mixing volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

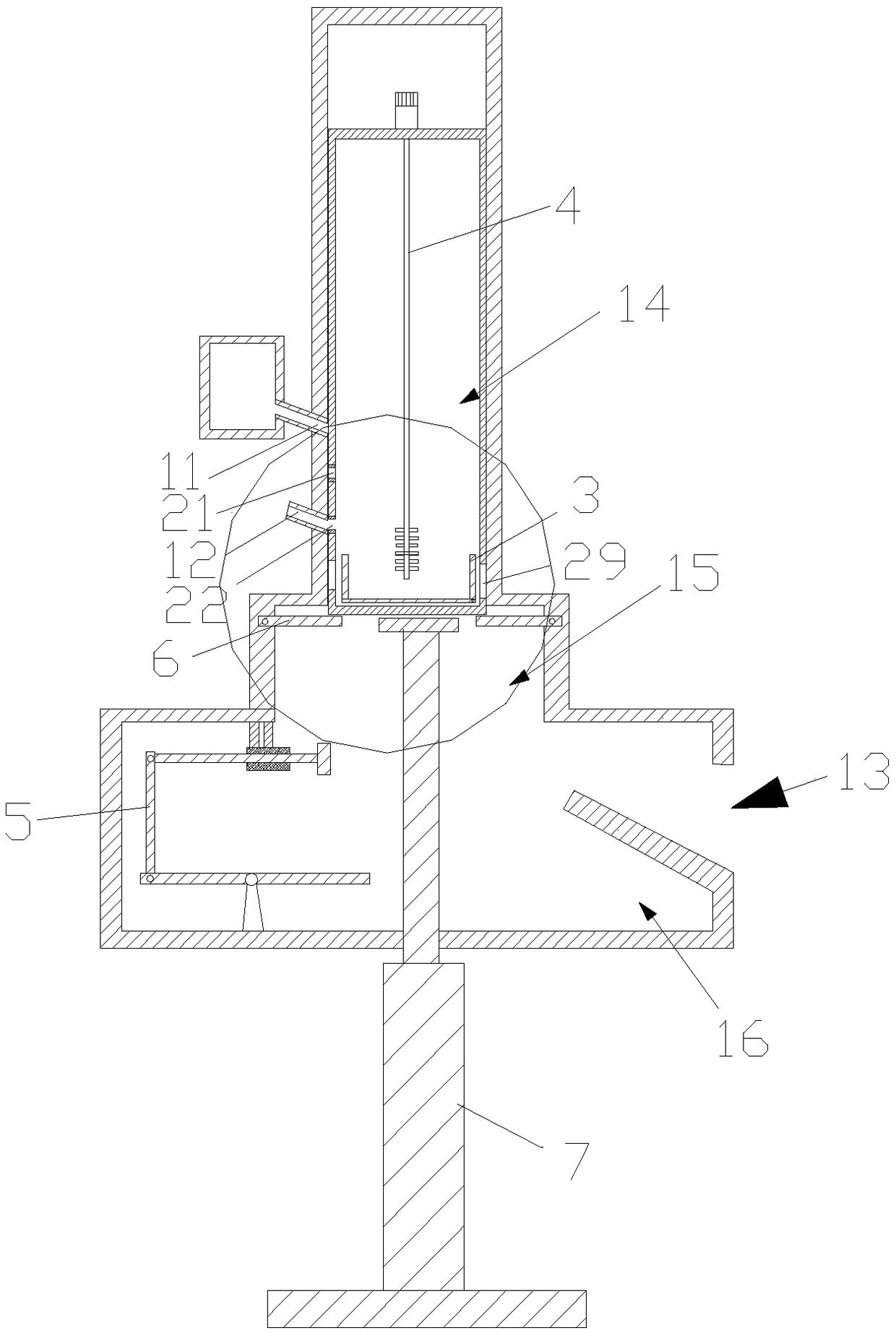

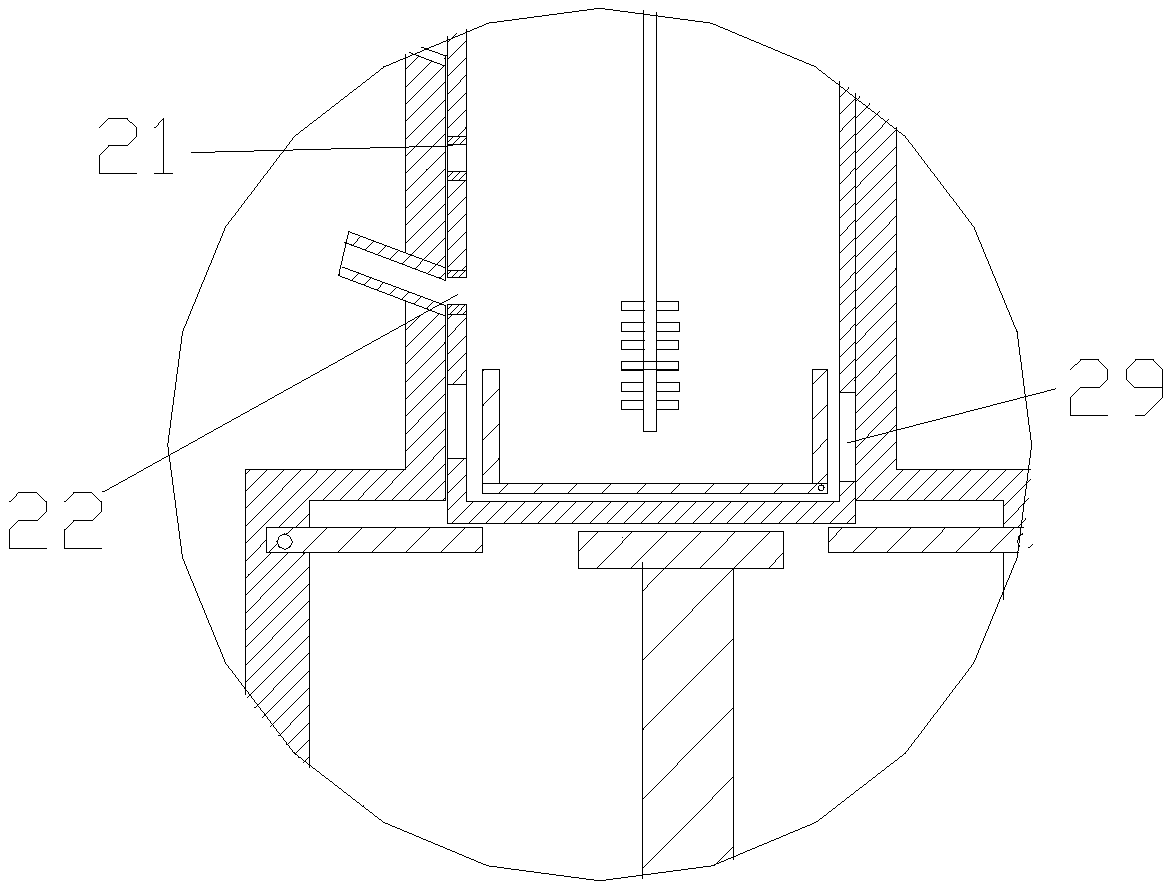

[0042] Such as Figure 1-3 As shown, this embodiment discloses a mixing and stirring device for the production of anti-scouring concrete for water conservancy projects, including a housing 1, a built-in frame body 2, a mixing chamber 3, a stirring member 4, a lever-type transmission pusher assembly 5, and a baffle Component 6, elastic support 7.

[0043] The housing 1 is separated from top to bottom with a feed inlet 11, a water inlet 12, and a discharge outlet 13. The inner cavity of the housing 1 includes a passage cavity 14 and a baffle installation cavity 15 that are connected to each other from top to bottom. , Bottom chamber 16. The cross-sections of the channel cavity 14, the baffle mounting cavity 15, and the bottom cavity 16 increase sequentially. Both the feeding port 11 and the water inlet port 12 communicate with the channel cavity 14 . The built-in frame body 2 is built in the inner cavity of the housing 1, wherein, the outer surface of the built-in frame body ...

Embodiment 2

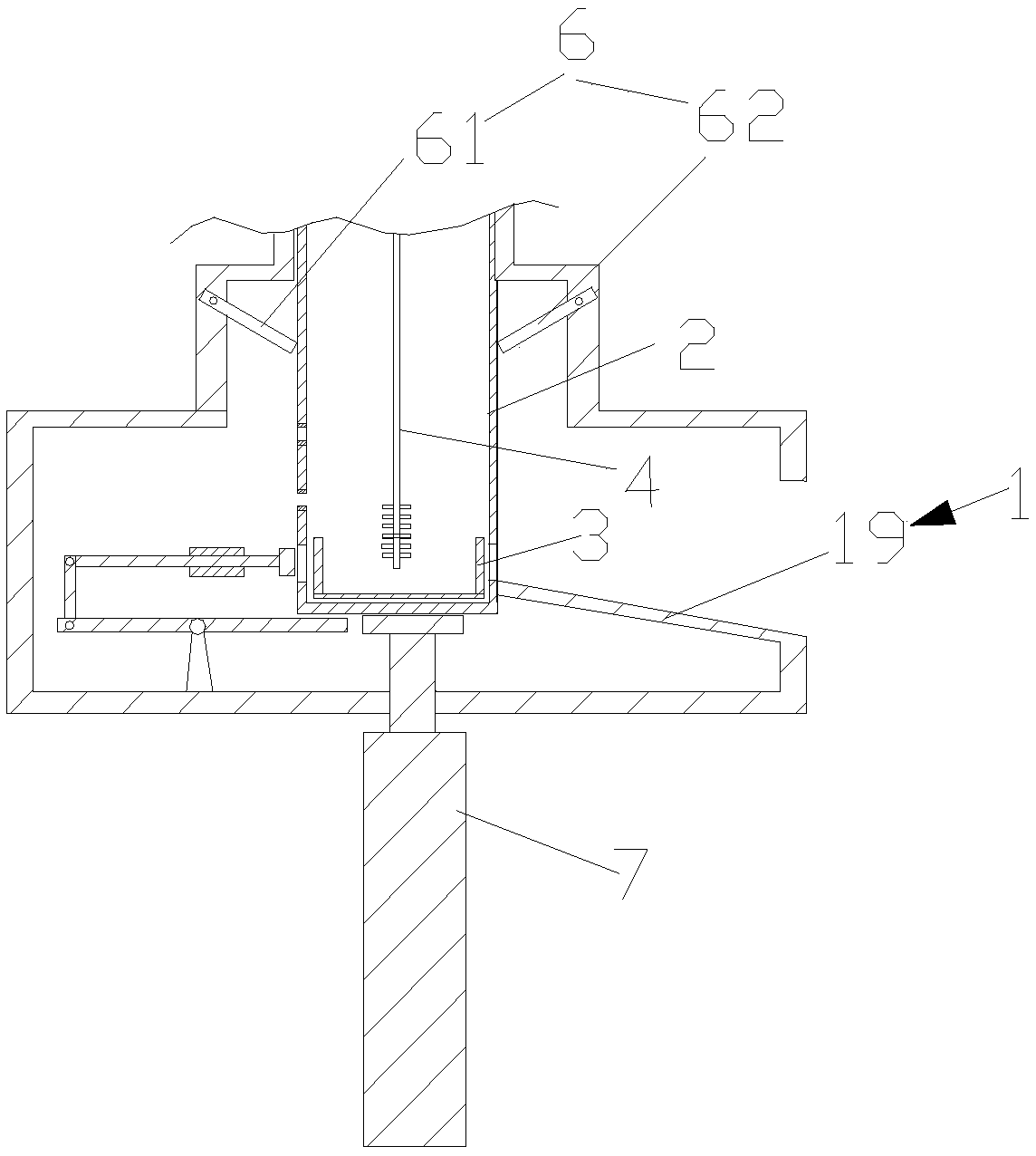

[0054] Such as Figure 1-3 As shown, the difference between this embodiment and the above-mentioned embodiments is that the baffle plate assembly 6 includes a mirror-symmetrical first baffle plate 61 and a second baffle plate 62, the hinged end of the first baffle plate 61, and the hinged end of the second baffle plate 62. The hinge ends are respectively hinged on both sides of the baffle installation cavity 15 . The length of the gap between the free end of the first baffle 61 and the free end of the second baffle 62 in a natural state is shorter than the length of the bottom of the housing 1 . The hinged end of each baffle is hinged to the inner sidewall of the baffle installation cavity 15 through a second torsion spring (not shown in the figure). The second torsion spring is assembled to the free end of the baffle in a horizontal state. When the free end of the baffle is in a horizontal state, the hinged end of the baffle can be attracted to the inner sidewall of the baf...

Embodiment 3

[0058] Such as Figure 5-6 As shown, the difference of the present embodiment compared with the foregoing embodiments is that the lever-type transmission pusher assembly 5 includes a lever 51, a transmission rod 52, a sleeve 53, and a push rod 54, and one end of the lever 51 is hinged with the lower end of the transmission rod 52, The upper end of the transmission rod 52 is hinged with one end of the push rod 54 , and the other end of the push rod 54 passes through the sleeve 53 so as to be in contact with or connected to the sliding push plate 33 . The other end of the lever 51 can be in contact with the bottom of the housing 1 .

[0059] When housing 1 descends to its contact with the other end of lever 51, the other end of lever 51 descends, and one end of lever 51 rotates upwards, drives transmission rod 52 to rotate, and drives push rod 54 to push sliding push plate 33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com