Material-saving type modular plastic formwork and construction method thereof

A technology of plastic formwork and construction method, applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problems of waste of resources, low recycling rate, easy damage of formwork, etc., to avoid cutting process, The effect of increasing the frequency of product use and improving the quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

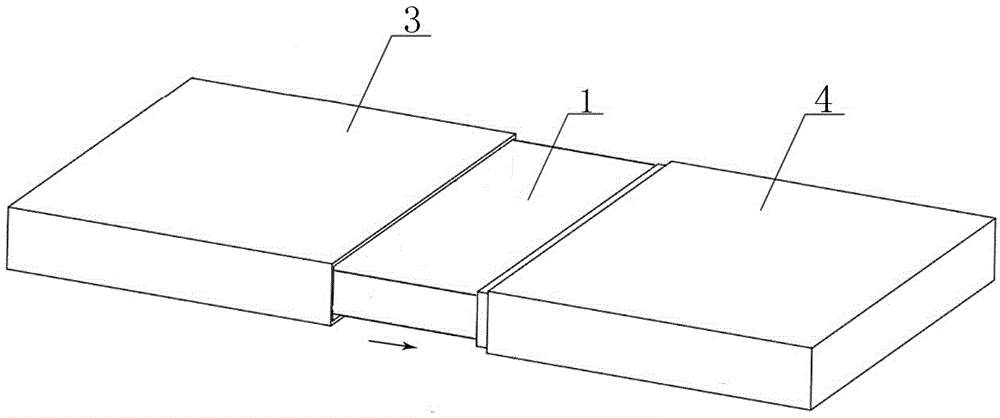

[0039] Embodiment one sees image 3 As shown, this kind of material-saving modularized plastic formwork includes a panel 1, the outer side of the panel 1 is covered with a skin 2, and the skin 2 is a hollow sealed box formed by at least two parts plugged together. The port position of the skin 2 is flush, and the joint position of the female and male joints is bonded by hot melt bonding, adhesive film bonding or glue liquid bonding. The formwork system has product size standards. The maximum size of the standard plate is 1800×900mm, and Take 300mm as the modulus in the length direction and width direction, and set other size standard boards.

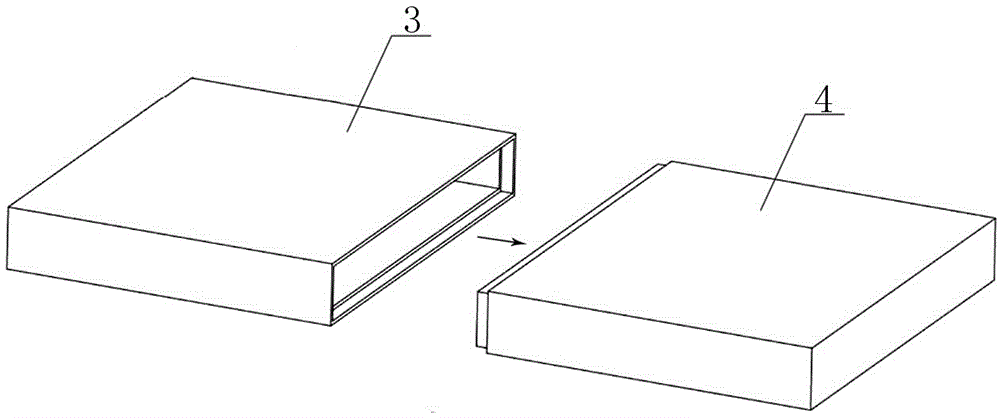

[0040] see figure 2 As shown, the skin 2 is made of thermoplastic, and after high impact modification and toughening modification treatment, the thickness of the four sides of the product formed by the skin is increased, and the protection of the skin to the panel is enhanced. The skin 2 is made of The skin A part 3 and the skin B par...

Embodiment 2

[0042] Embodiment two see Figure 4 As shown, different from Embodiment 1, the epidermis 2 is composed of an epidermis body A5 and an epidermis cover A6, wherein the epidermis body A5 is a rectangular box-shaped structure, and its open end is connected with an epidermis cover A6. Or through the socket connection of the female and male joints used in conjunction with the ends.

Embodiment 3

[0043] Embodiment three see Figure 5 As shown, the difference from Example 1 is that the skin 2 is composed of a skin body B7 and two skin covers B8, wherein the rectangular cylinder structure of the skin body B7 and the open ends on both sides are all used together. The male-female joint socket connection has a skin cover B8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com