Leaking stoppage method for abutted seam of fabricated building precast beam and precast composite floor

A technology of laminated floor slabs and plugging methods, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems that the sealant strips cannot reach the caulking, grout leakage, and sealant are greatly affected, and achieve the goal of solving leaks. Pulp problems, saving project cost, and avoiding the effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

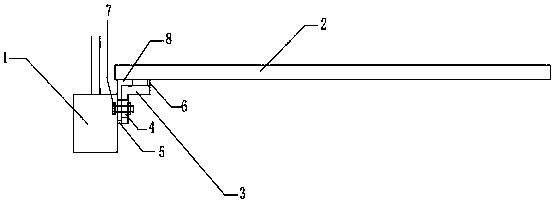

[0014] like figure 1 Shown: a prefabricated building prefabricated beam and prefabricated laminated floor joint joint plugging method, which includes:

[0015] Step 1, install the prefabricated beam 1 and the prefabricated laminated floor 2, set bolt holes near the prefabricated beam, and pre-embed the bolt 7; Step 2, install the blocking member 3, which is a rigid L-shaped member with two The outer sides are flexible waterproof material surfaces 5, 6, 8, and the through holes 4 corresponding to the bolt holes are set at the joints of the prefabricated laminated floors, and the flexible waterproof material surfaces on the outer sides of the components fit with the bottom of the laminated floors through manual adjustment. , accompanied by a certain extrusion force, to complete the vertical compaction, and then adjust the holes horizontally and horizontally, so that the flexible waterproof material surface of the component caulking fits with the prefabricated beam, and completes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com