Formwork system for inverted circular truncated cone-shaped cup opening of column foundation of steel structure factory building and construction method

A technology of rounded truncated truncated steel structure, which is used in infrastructure engineering, formwork/formwork/work frame, on-site preparation of building components, etc., can solve problems such as failure to meet quality requirements, slurry leakage, and impact on concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

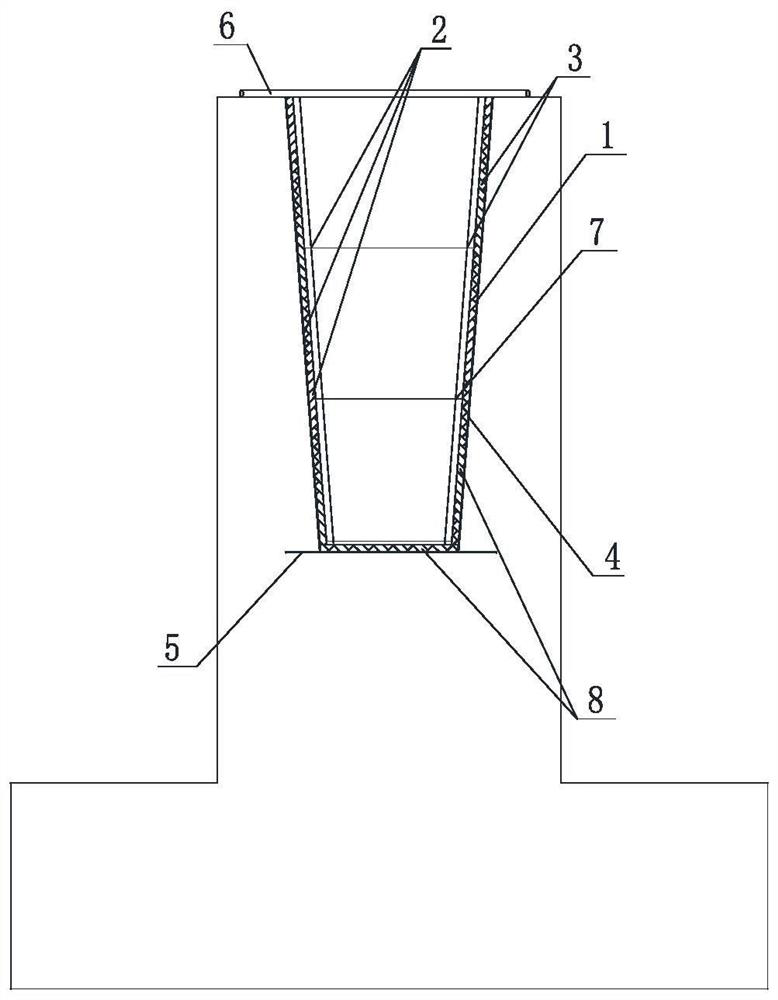

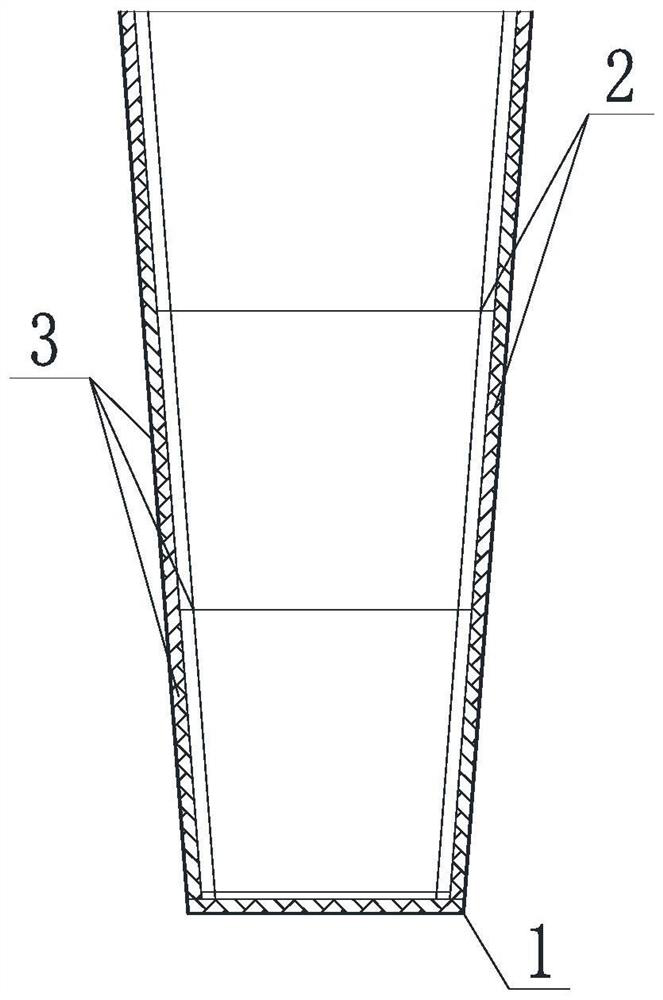

[0035] The purpose of the present invention is to provide a combined formwork method for a rounded frustum-shaped cup mouth of a column base, so as to solve the problem of insufficient concrete strength due to damage to concrete caused by improper methods in existing construction or excessive size variation caused by grout leakage. And other quality problems, to ensure the quality of cup molding.

[0036] The technical solution of the invention is:

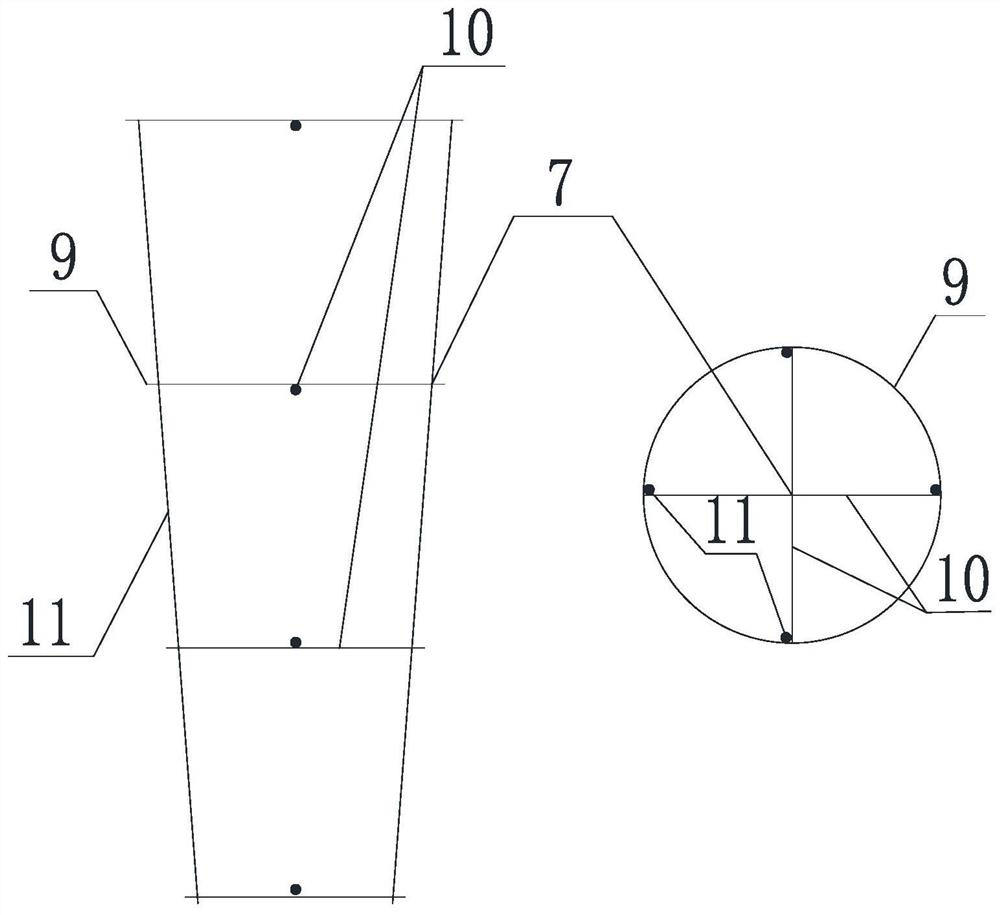

[0037] Step 1: Design the components of the combined formwork support method, including the internal support frame, the above-mentioned inner membrane carcass, side flexible panels, fixed panel wooden strips, bottom sealing formwork, bottom supporting horse stool bars, and top anti-floating pressure rods.

[0038] Step 2: Stake out and manufacture each part according to the size of the rounded truncated cup mouth of the column base.

[0039] The internal support frame is composed of circular circular support ribs (4 horizontally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com