Concrete beam form supporting device and construction process thereof

A formwork support and concrete beam technology, which can be applied to formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc., can solve the lack of effective oblique support on the side, installation Difficulties, beam formwork expansion and other problems, achieve the effect of realizing multiple turnover and reuse, reducing construction costs, and solving the problem of slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

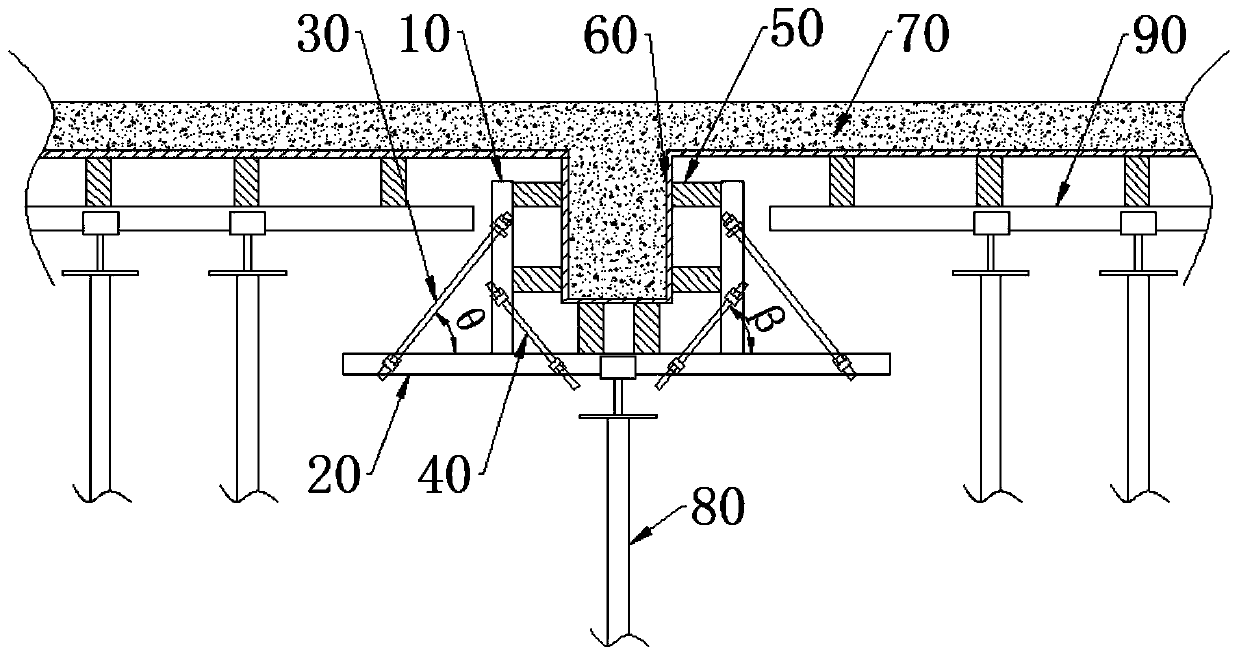

[0038] In the interior structure of housing construction projects, such as figure 1 As shown, there are often downward protruding beams in the roof of the house. The cross section of the beams is relatively small, the height generally does not exceed 500mm, and the width is between 200-300mm. However, during the construction process, the beam formwork 60 needs to be built in advance, so that the internal structure of the beam formwork 60 is compatible with the outer wall structure of the house beam. Horizontal top templates 70 are also provided on both sides of the beam template 60 of the house beam, and the top template 70 is integrally connected with the beam template 60 . Before actually pouring concrete, the top formwork 70 is fixed on the crossbeam 90 through the wooden square 50, and the crossbeam 90 is fixed on the scaffold 80. If the beam formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com