Building automatic formwork connecting system and precise positioning system thereof

A technology for automatic and precise positioning of buildings, which is applied in the fields of construction, building structure, and on-site preparation of building components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

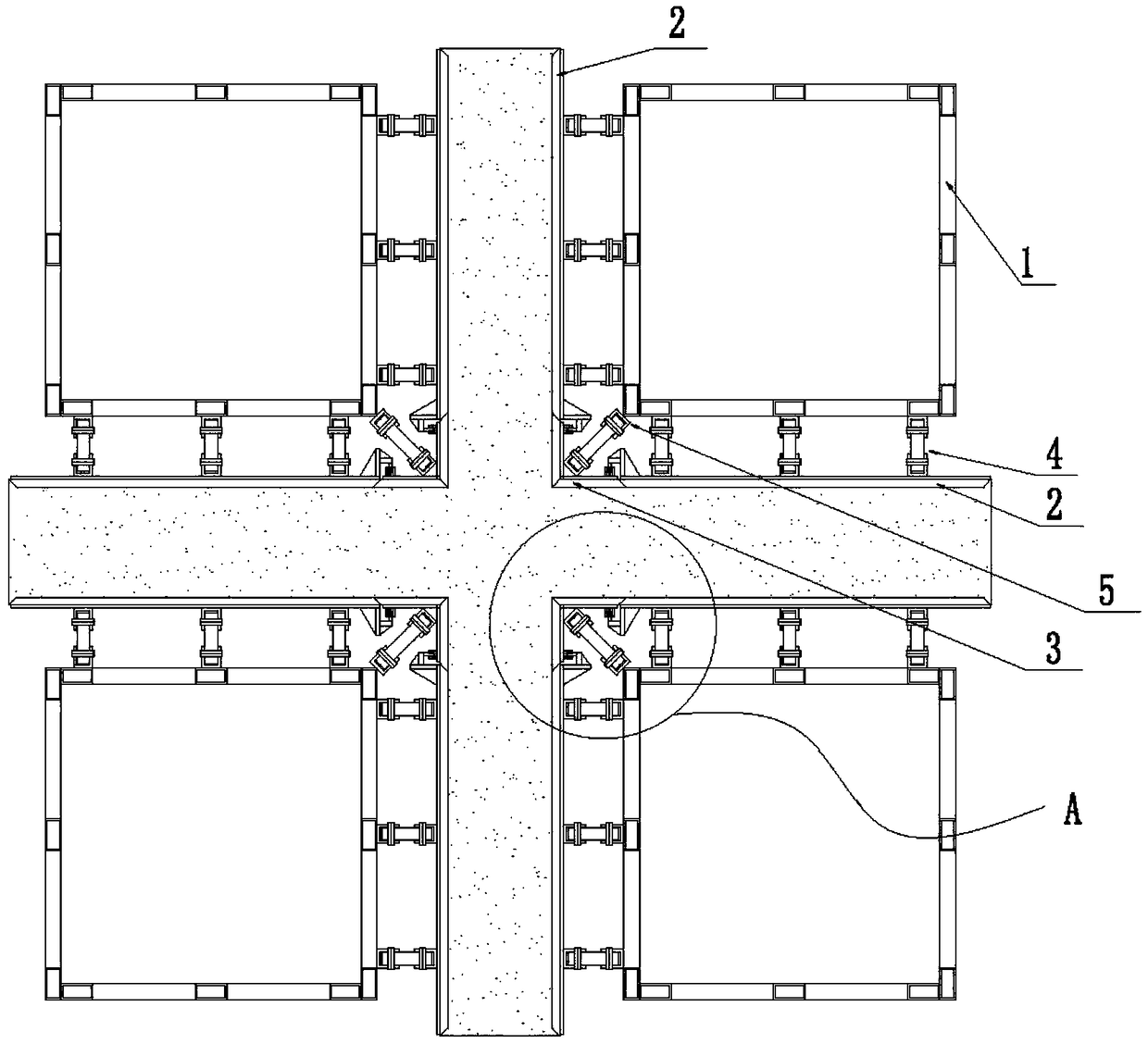

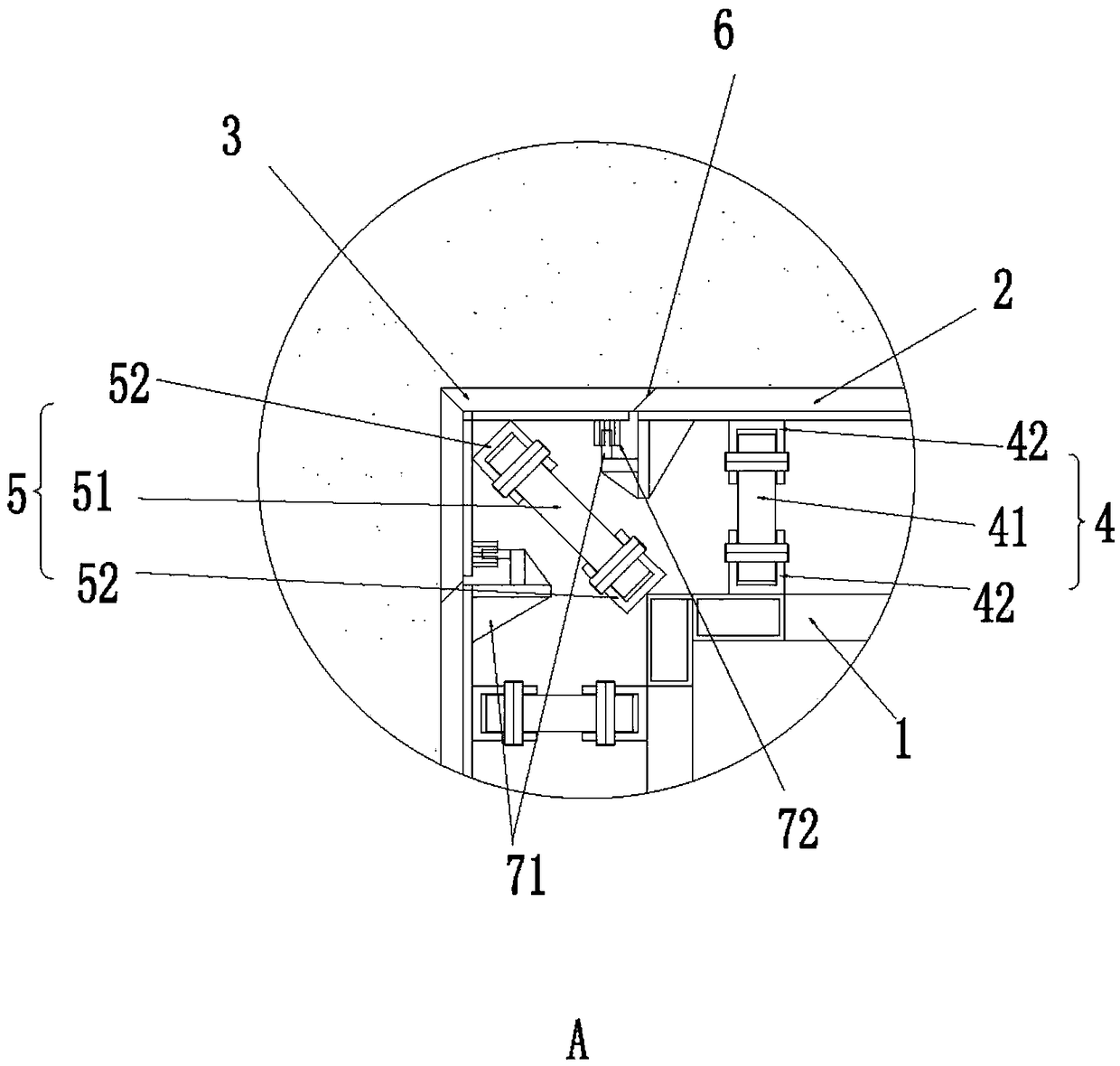

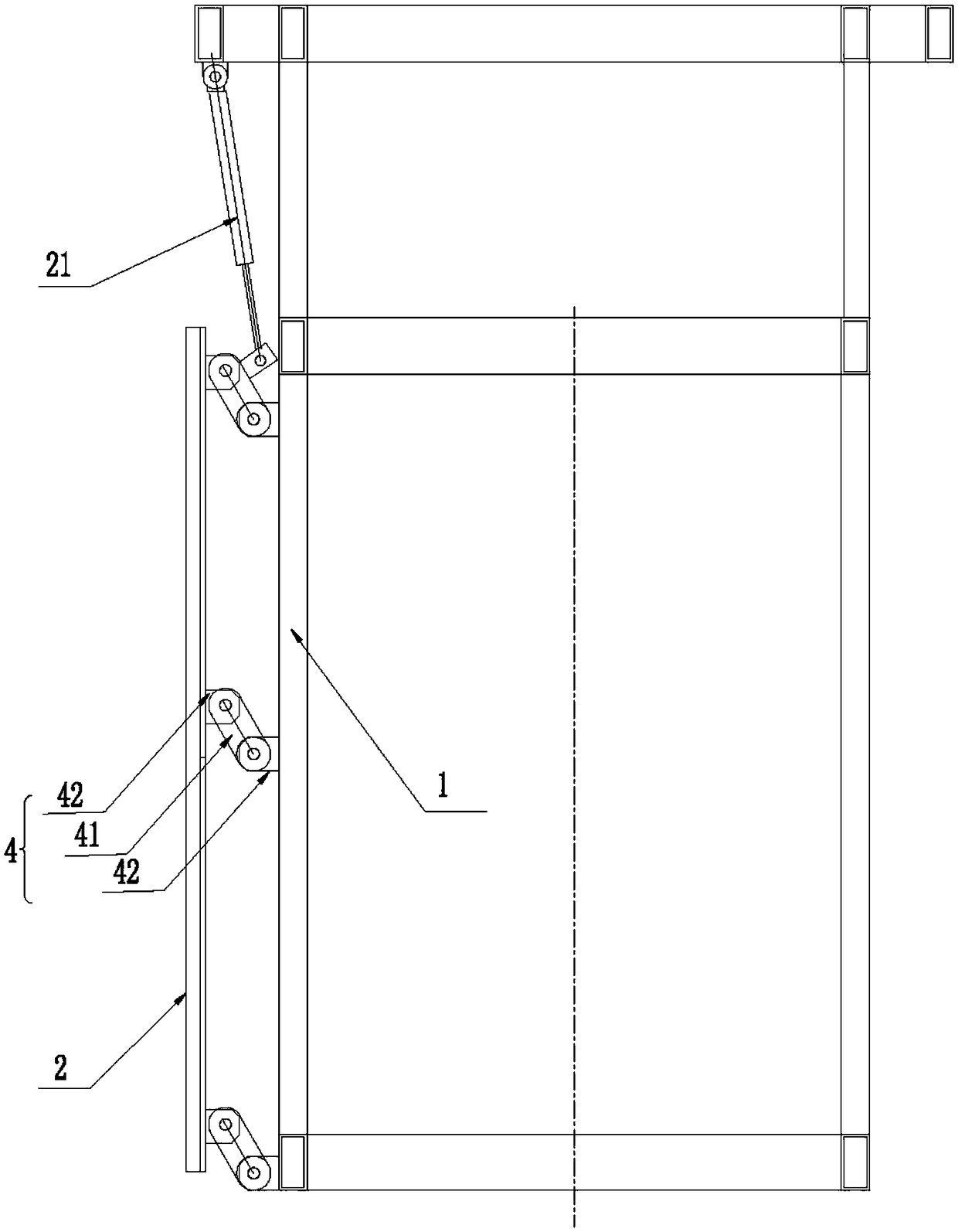

[0028] The specific implementation of the building automatic mold clamping system of the present invention, as Figure 1 to Figure 4 As shown, it includes a center frame 1, a second formwork 3, a first formwork 2 and at least two connecting rod assemblies, image 3 It is a schematic diagram of the structure of the opening and closing device in the mold opening state, Figure 4 It is a schematic diagram of the structure of the opening and closing device in the mold closing state.

[0029] please see figure 1 and figure 2 , first of all, it should be explained that in this embodiment, the first template 2 is a flat template, the second template 3 is a corner template, and the angle between the corner templates is a right angle. The above design method is mainly suitable for cross-shaped walls Or a wall with a right-angled corner, of course, both the first template 2 and the second template 3 can be flat templates, which are suitable for long flat walls, and the specific shap...

Embodiment 2

[0038] The second specific implementation mode of the building automatic mold clamping precise positioning system of the present application, such as Figure 5 As mentioned above, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that both the first template 2 and the second template are flat templates. Of course, it can also be set that the first template 2 is a flat template and the second template 3 is a corner template. The holder is a positioning groove 81 horizontally arranged on the back of the first template 2, and the second clamping member is a positioning block 82 horizontally arranged on the back of the second template 3. In the clamped state, the positioning block 82 is inserted into the positioning groove 81 and engaged; The notch of the positioning groove 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com