Dual sealing device for feeding of ball mill

A double-sealing, ball mill technology, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems of non-abrasion-resistant seals, leakage of slurry at the feed port of the ball mill, frequent replacement, etc., to prolong the service life and simplify the adjustment. , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

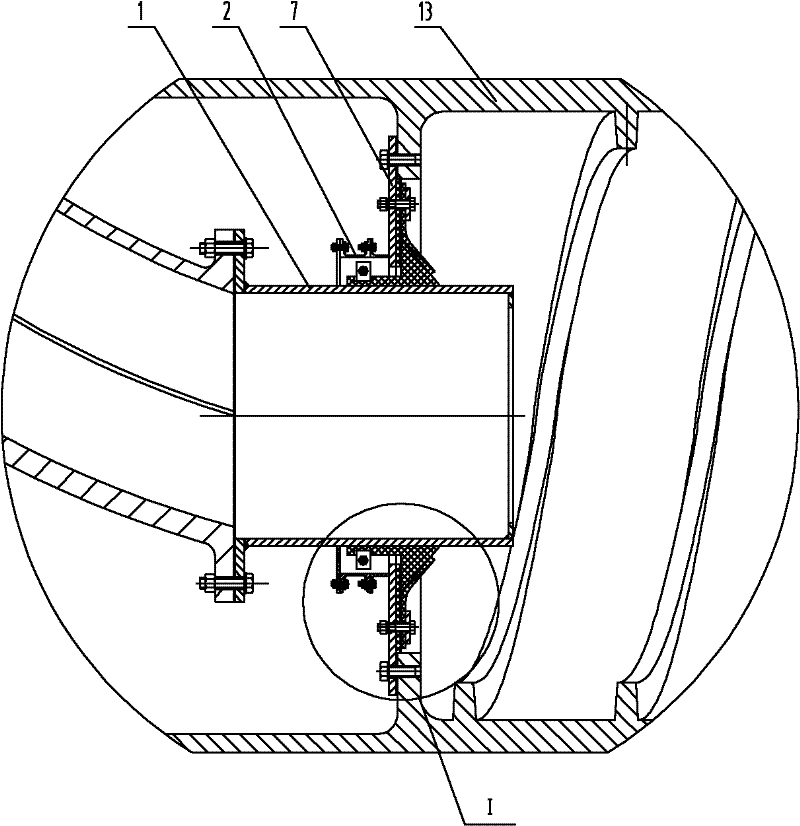

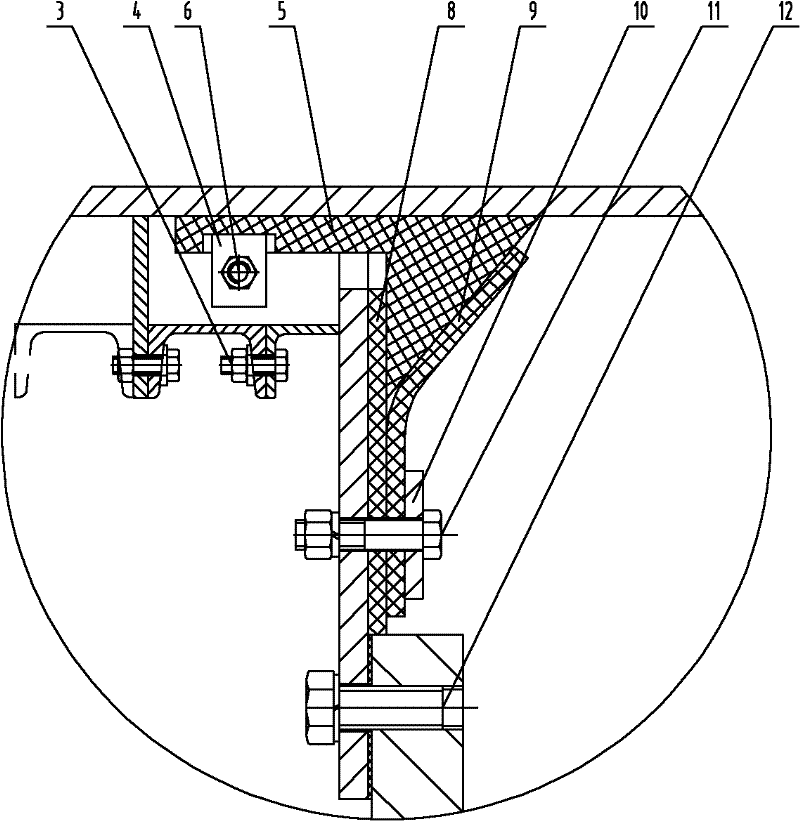

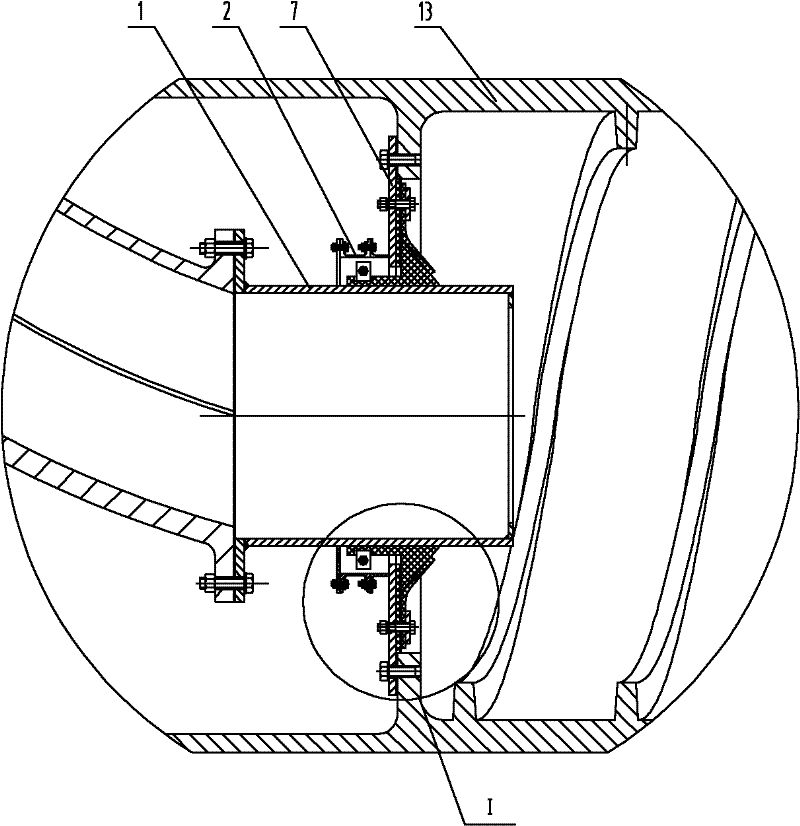

[0010] Referring to the accompanying drawings, a ball mill feed double sealing device is composed of feed pipe 1, auxiliary installation beam 2, closing bolt 3, compression snap ring 4, compression corner seal rubber 5, adjustment bolt 6, mounting flange 7. The inner wear-resistant rubber plate 8, the outer wear-resistant rubber plate 9, the pressure plate 10, the pressure plate bolt 11, the mounting flange bolt 12, and the feed bushing 13. The ball mill feed double sealing device is composed of an auxiliary installation beam 2. The installation flange 7, the inner wear-resistant rubber plate 8, the pressure plate 10, the outer wear-resistant rubber plate 9 and the compression angle sealing rubber 5 are assembled; during installation, the installation flange 7 is fixed on the On the feed pipe 1, the compressed angle-shaped sealing rubber 5 is fixed on the feed pipe 1 through the compression snap ring 4, one side of which is in parallel contact with the inner wear-resistant rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com