Hydraulic device for moulding board of precast beam

A hydraulic device and beam formwork technology, which is applied in the field of hydraulic devices, can solve problems such as easily damaged beam surface and beam leakage, and achieve the effects of reducing knock damage, avoiding collisions, and improving efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

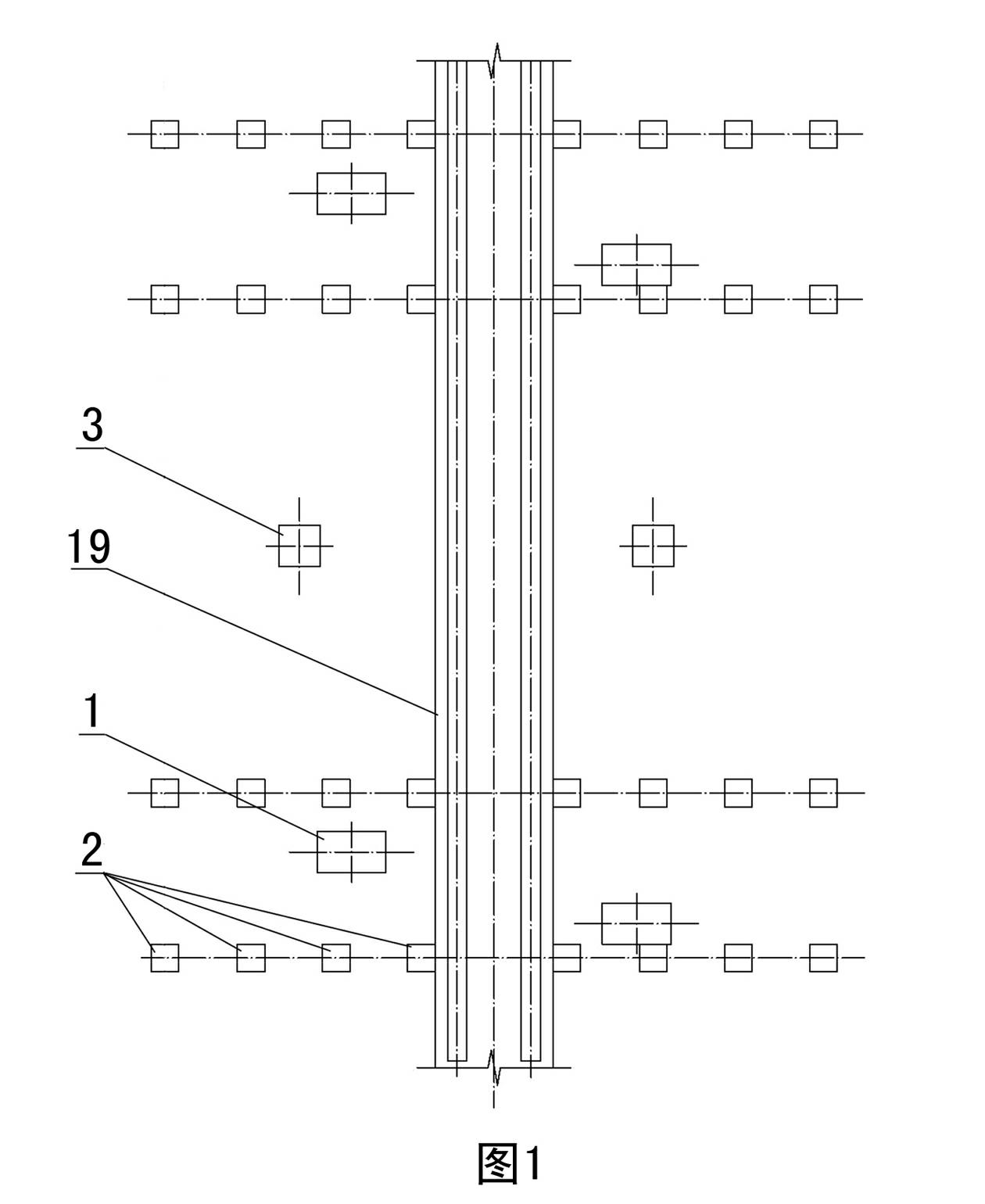

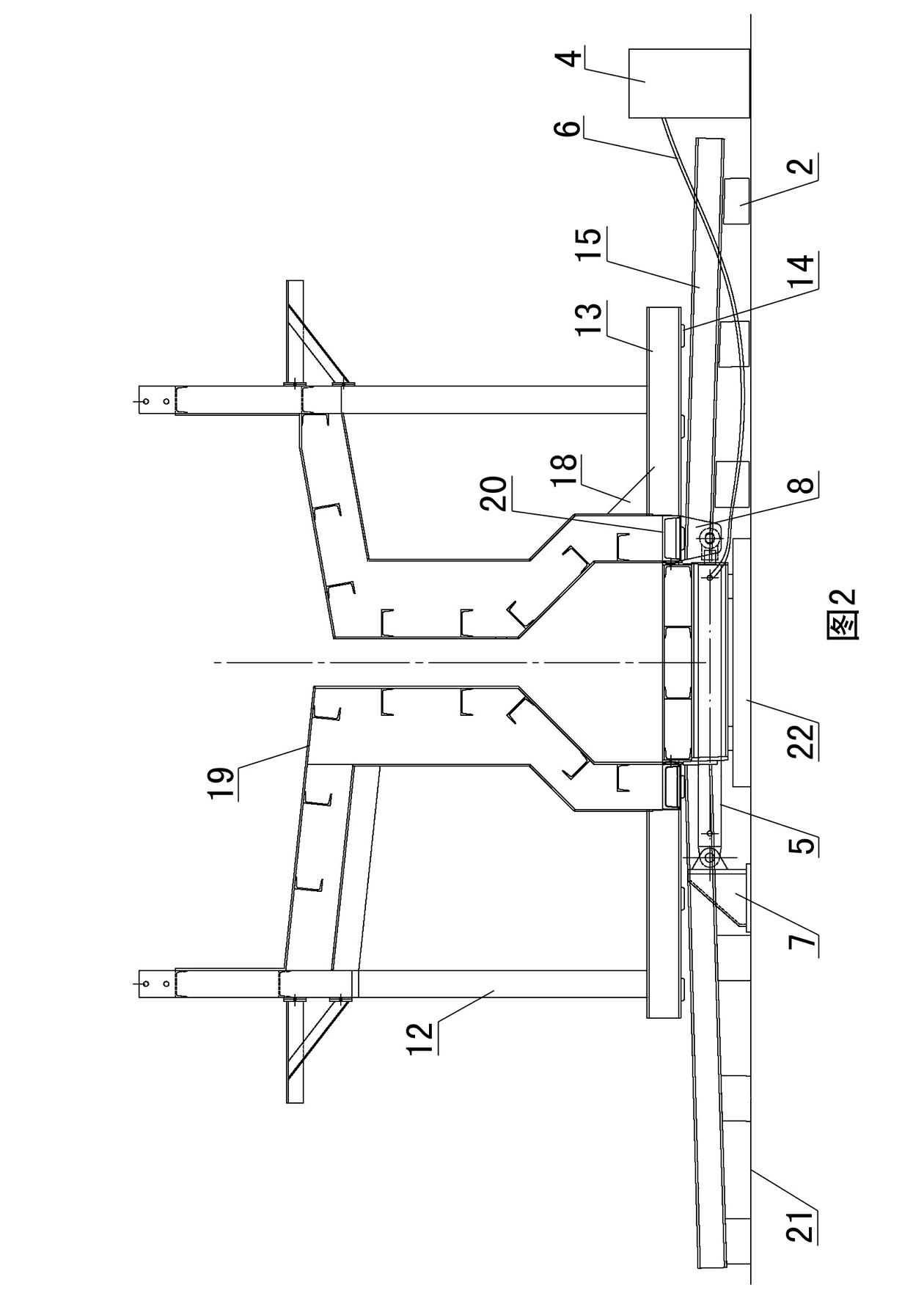

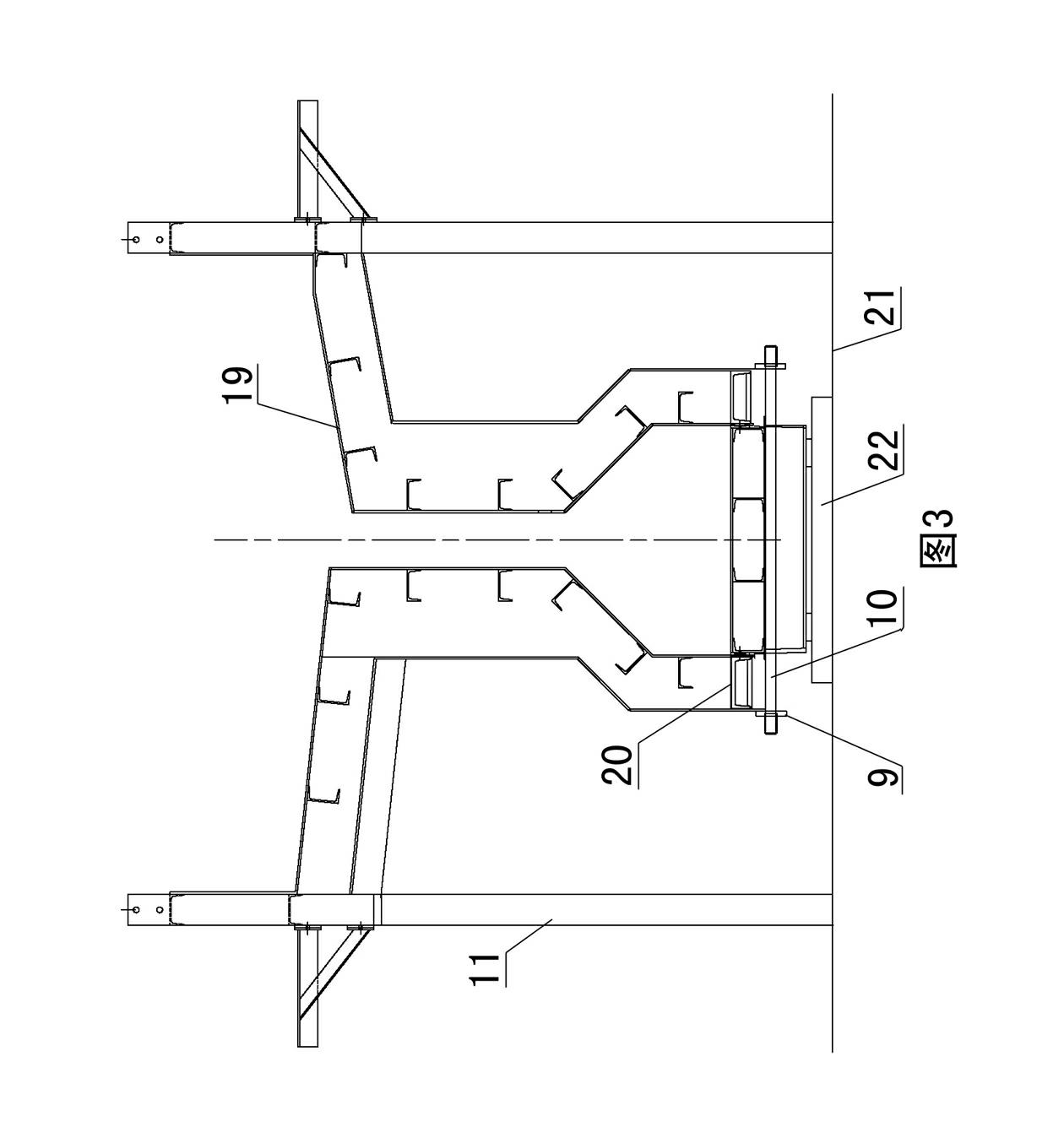

[0033] Examples see Figure 1-3 As shown, this prefabricated beam formwork hydraulic device is connected between the precast concrete T-beam formwork 19 and the ground 21, and is composed of foundation embedded parts, hydraulic system, slideway system and positioning system. The foundation embedded parts are pre-buried on the ground 21 on the left and right sides of the precast concrete T-beam formwork 19, including hydraulic cylinder base embedded parts 1, pad rail foundation embedded parts 2 and vertical tie rod foundation embedded parts 3, wherein the pad The rail foundation embedded parts 2 are symmetrically distributed on the left and right sides of the precast concrete T beam form 19 with the precast concrete T beam form 19 as the center line.

[0034] see figure 2 , Figure 4 , Figure 9-11 , the hydraulic system includes a hydraulic pump station, a hydraulic control valve block 4, a hydraulic cylinder 5 and a high-pressure oil pipe 6, wherein one end of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com