High-pressure circulation grouting minitype steel pipe pile and construction method thereof

A technology of high-pressure circulation and steel pipe piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reduced bearing capacity, disturbed soil around piles, and reduced integrity of steel pipes, and achieves enhanced compressive strength, Enhanced frictional resistance, shaping and toughness-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

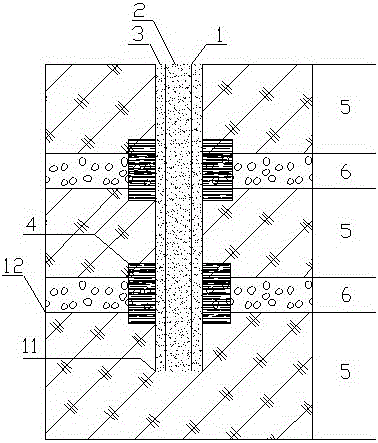

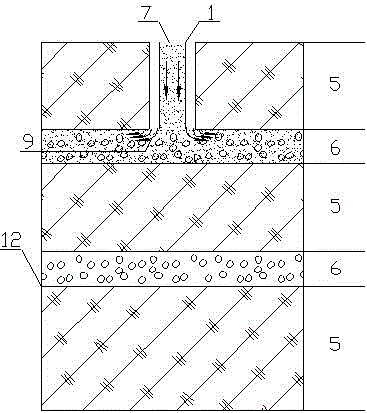

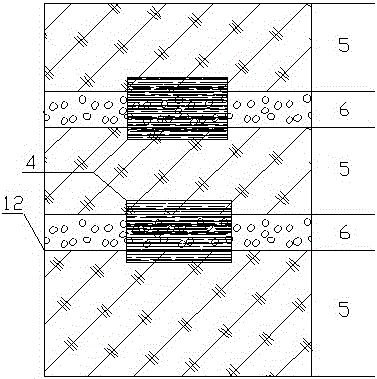

[0031] Such as Figure 1~6 As shown, the present invention is a high-pressure circulating grouting micro-steel pipe pile and its construction method. The micro-steel pipe pile includes a micro-steel pipe 1, a cement paste filling body 2, a cement paste protection layer 3 and a leak-proof sleeve pile 4. The micro-steel pipe 1 is spliced by a plurality of steel sleeves with a length of 1m through its own threaded connection. The specific number of steel sleeves is determined by the actual pile length. The slurry protection layer 3; for the project where there is a slurry leakage layer 6 in the underground soil, the micro-steel pipe 1 passes through the anti-leakage sleeve pile 4 formed by the rotary spraying treatment at each slurry leakage layer 6 in turn.

[0032] The diameter of the micro-steel pipe pile is 180mm-360mm, wherein the micro-steel pipe 1 is selected according to the steel casing specification table and has a diameter of 150mm-300mm, and the thickness of the cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com