Workbench for manufacturing pressure grouting mold

A workbench and grouting technology, used in manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve problems such as slurry leakage, achieve high strength and flatness, ensure flatness, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be described in further detail below in conjunction with the drawings, wherein the same symbols in all the drawings represent the same or similar components, and the drawings in the description are in simplified form and are only for understanding the specific structure of the present invention. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

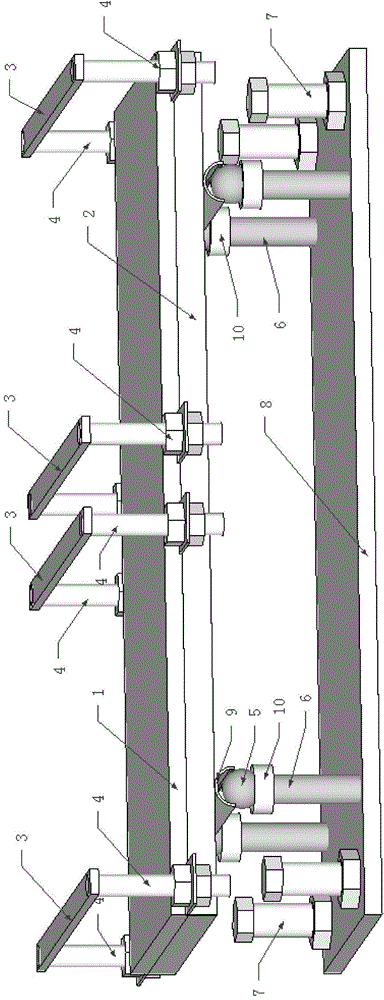

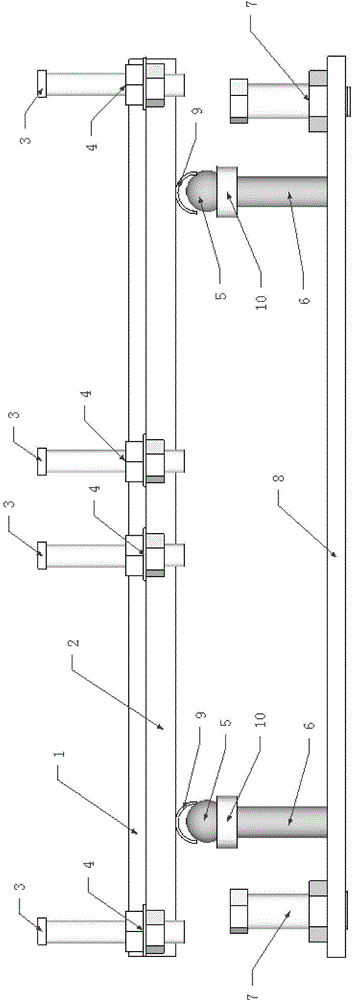

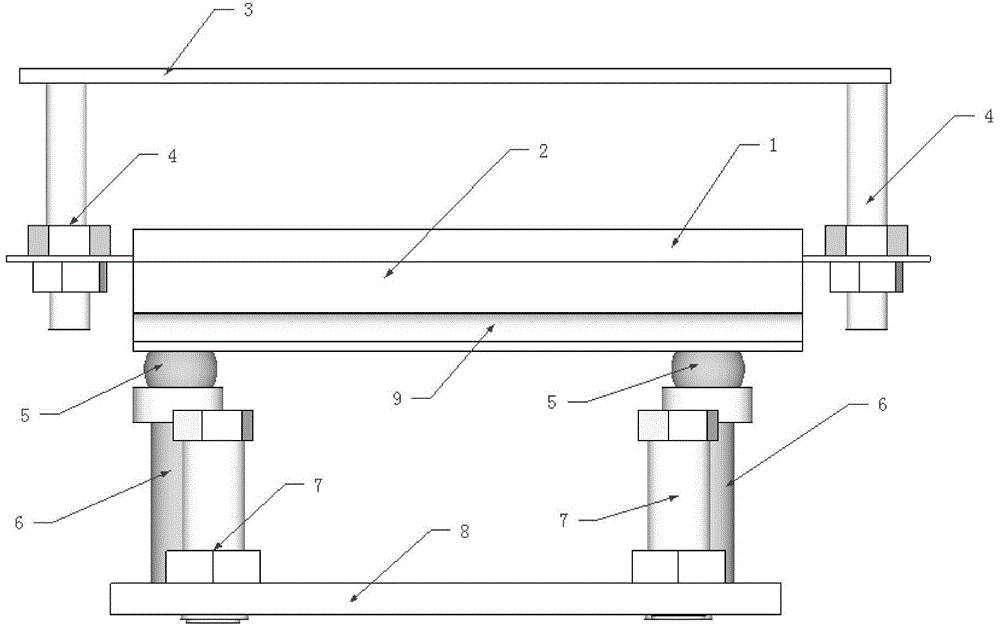

[0026] Such as figure 1 , figure 2 , image 3 Shown, a kind of workbench of making pressure grouting mould, comprises workpanel 1, frame 2 fixed on the lower surface of workpanel, is located at the lower panel 8 directly below the workpanel, horizontal frame mechanism, and described horizontal frame mechanism consists of The four horizontal frame members are divided into two groups and arranged vertically and uniformly on the working panel 1, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com