Lining construction method for suspension rail type trolley

A construction method, a suspended rail technology, is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc. It can solve the problems of slow construction speed, poor quality, and high man-hour consumption, and achieve convenient and continuous construction, good pressure bearing capacity, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

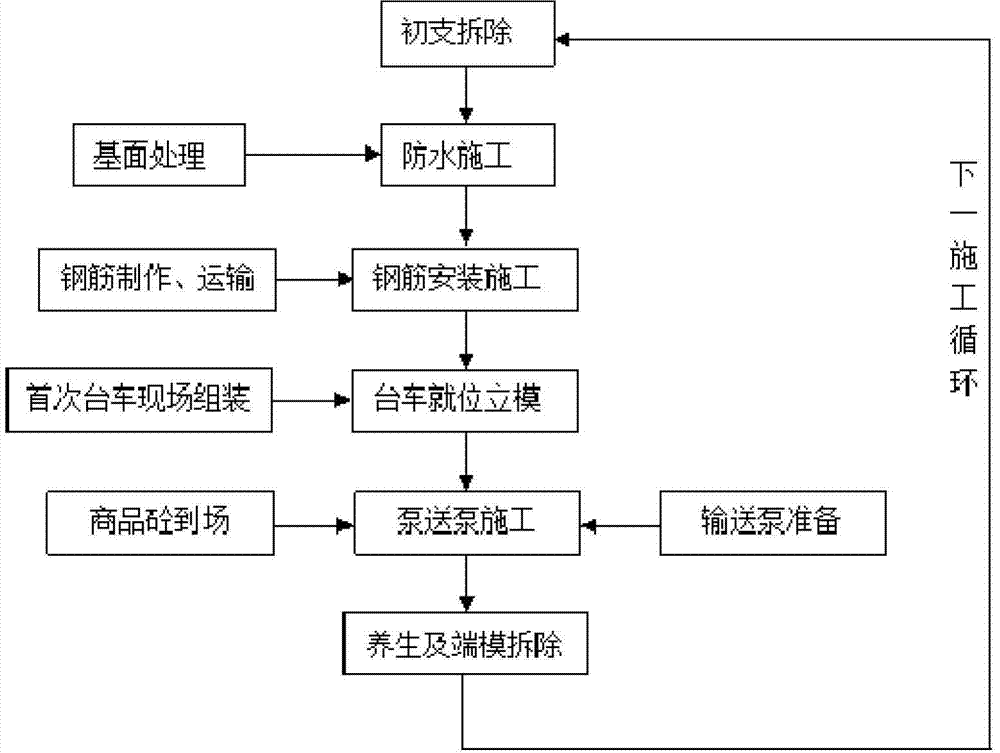

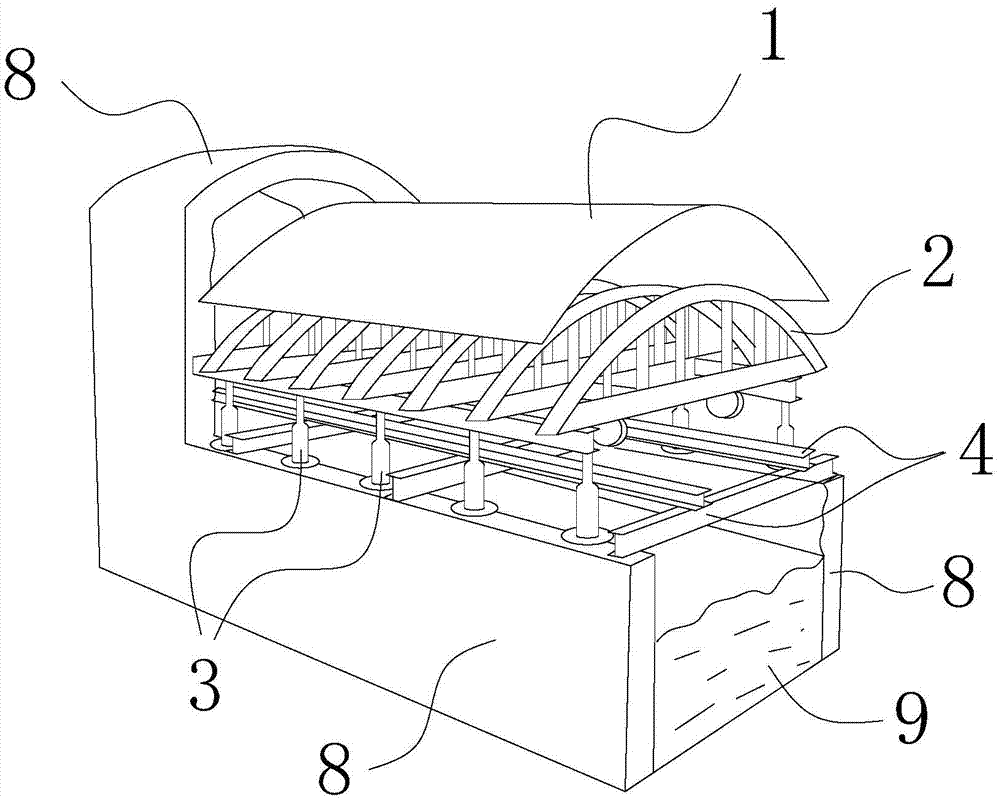

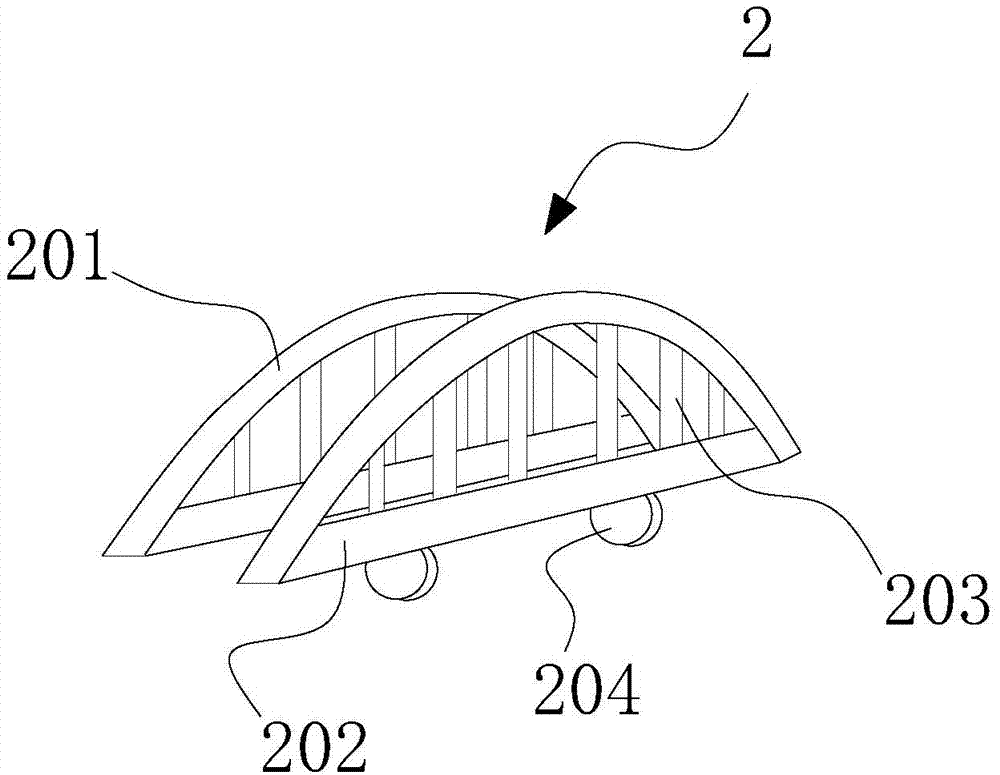

[0074] Such as figure 1As shown, in the PBA construction method, the initial support of the pilot tunnel is not completely removed, and the unremoved initial support is used as the main support platform for the trolley formwork and movement. The trolley is composed of I-shaped steel formwork + adjustable formwork. The length of the trolley is 7.5m. ) set a span every 0.75m, each trolley has a total of 11 sets of formwork, which are welded on the I20 longitudinal double-split I-beam (or box steel structural steel) at a distance of 0.75m; between each two sets of formwork Steel pipe connection (set 6 for each group of formwork) to ensure its stability; the formwork adopts 1500x750x5mm adjustable steel formwork, the long side is arranged longitudinally along the buckle arch, the formwork is directly fixed with bolts, and the formwork is welded and fixed with the formwork after assembly. There are 25t screw jacks under the vertical double-span I-beam, and the screw jacks are set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com