Prefabricated box girder end die capable of being rapidly positioned and dismounted

An end-die and fast technology, applied in the direction of molds, manufacturing tools, mold trays, etc., can solve the problems of slow speed, affecting the quality of the beam body, and difficulty in dismantling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

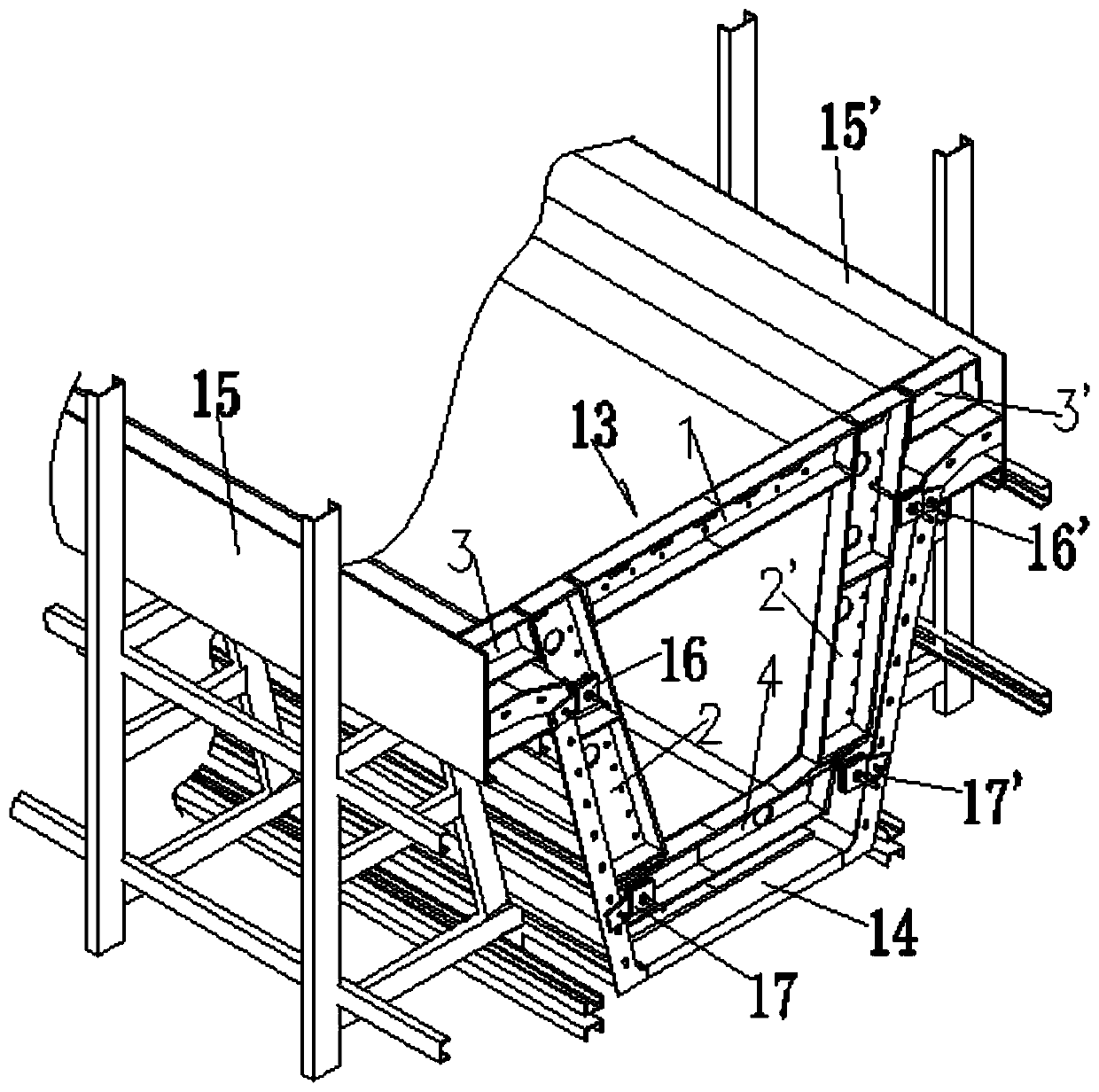

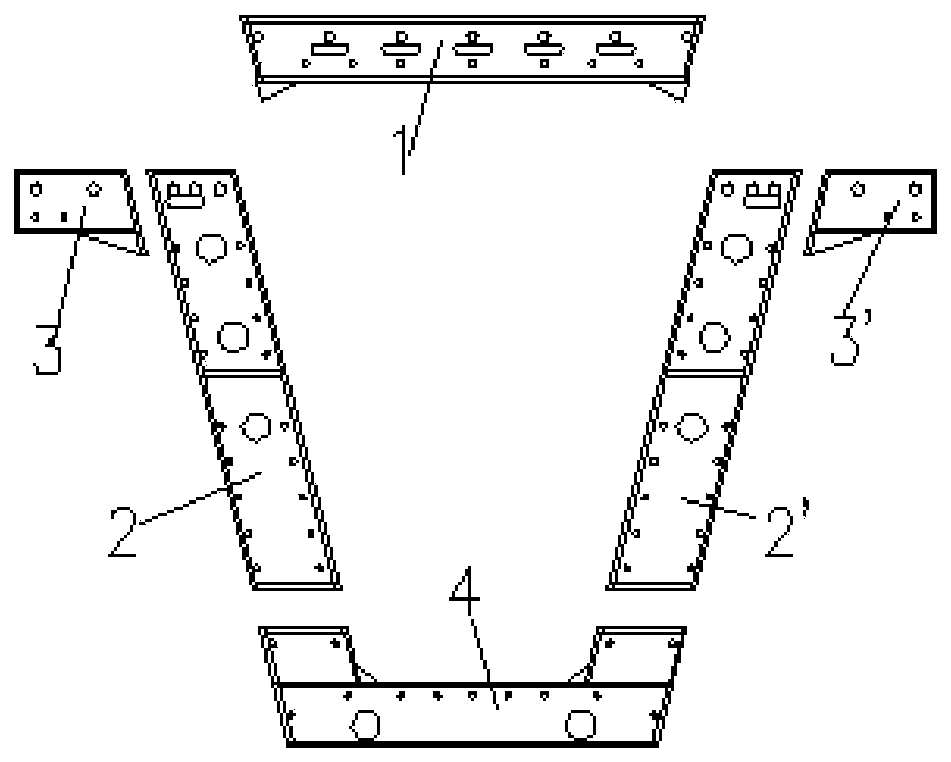

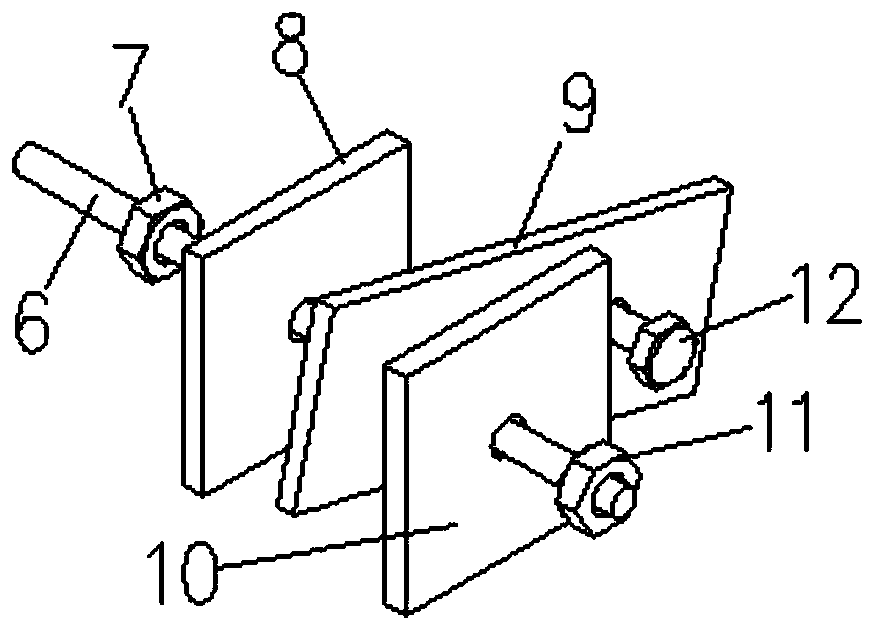

[0020] given by the present invention figure 1 , figure 2 , image 3 and Figure 4 In the embodiment, a prefabricated box girder end form that can be quickly positioned and removed is processed into an end form (integral) 13 with section steel, and the end form 13 is composed of a top plate 1, a left web 2, a right web 2', and a left flange 3 , the right flange plate 3', the bottom plate 4, and the comb plate 5; the two ends of the top plate 1 are respectively welded on the inner side of the upper end of the left web 2 and the right web 2', and are connected with the left web 2 and the right web 2 The upper ends are flush with each other; the left flange plate 3 and the right flange plate 3’ are respectively welded on the outer sides of the upper ends of the left web plate 2 and the right web plate 2’, and the left flange plate 3 and the right flange plate 3’ are connected to the upper top plate 1. Flat; the bottom plate 4 is welded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com