Separate bin grouting method

A technology of silo separation and grouting, which is applied in construction, building structure, construction material processing, etc., to achieve the effect of simple and fast construction operation, ensuring the safety of engineering structure and construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

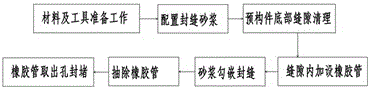

[0020] A grouting method in separate bins, characterized in that: comprising the following steps;

[0021] 1. Material preparation:

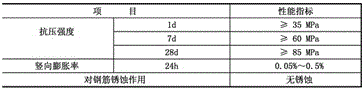

[0022] (1) 20kg bags of CGMJM-Ⅵ high-strength slurry have an initial setting time of 3 hours and 40 minutes at 20°C and 2 hours at 35°C. The performance parameter table of CGMJM-Ⅵ high-strength slurry is attached. figure 1 .

[0023] (2) Drinking water. Drinking water should be used for mixing mortar. When using other water sources, it should meet the requirements of the "Concrete Mixing Water Standard" (JGJ63).

[0024] 2. Preparation of construction machinery and tools.

[0025] (1) 100 kg floor scale (for weighing water and materials);

[0026] (2) Mercury thermometers and surface thermometers;

[0027] (3) 200ml measuring cylinder;

[0028] (4) Mixing barrel with a volume of 200-300L;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com