Oblique curtain wall system and installation method thereof

A curtain wall and floor slab technology is applied in the field of slanted glass curtain wall and its construction, which can solve the problems of difficulty in high-rise construction of slanted curtain wall and difficulty in ensuring construction safety, and achieve the effect of convenient temporary fixation, meeting the needs of construction technology and beautiful overall effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

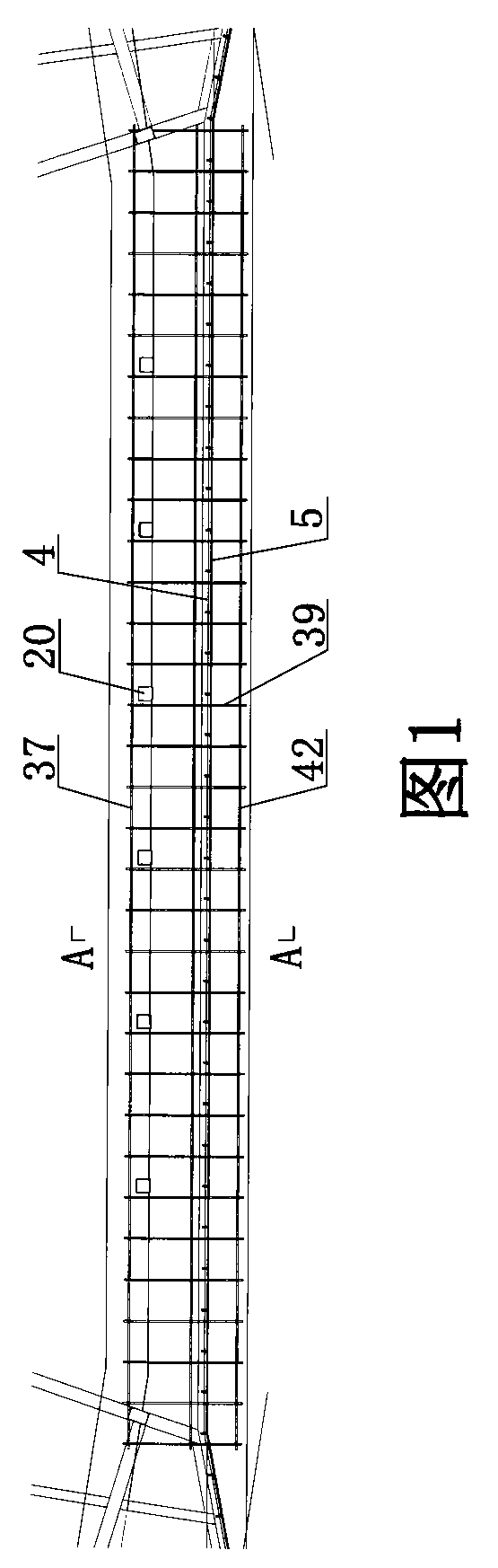

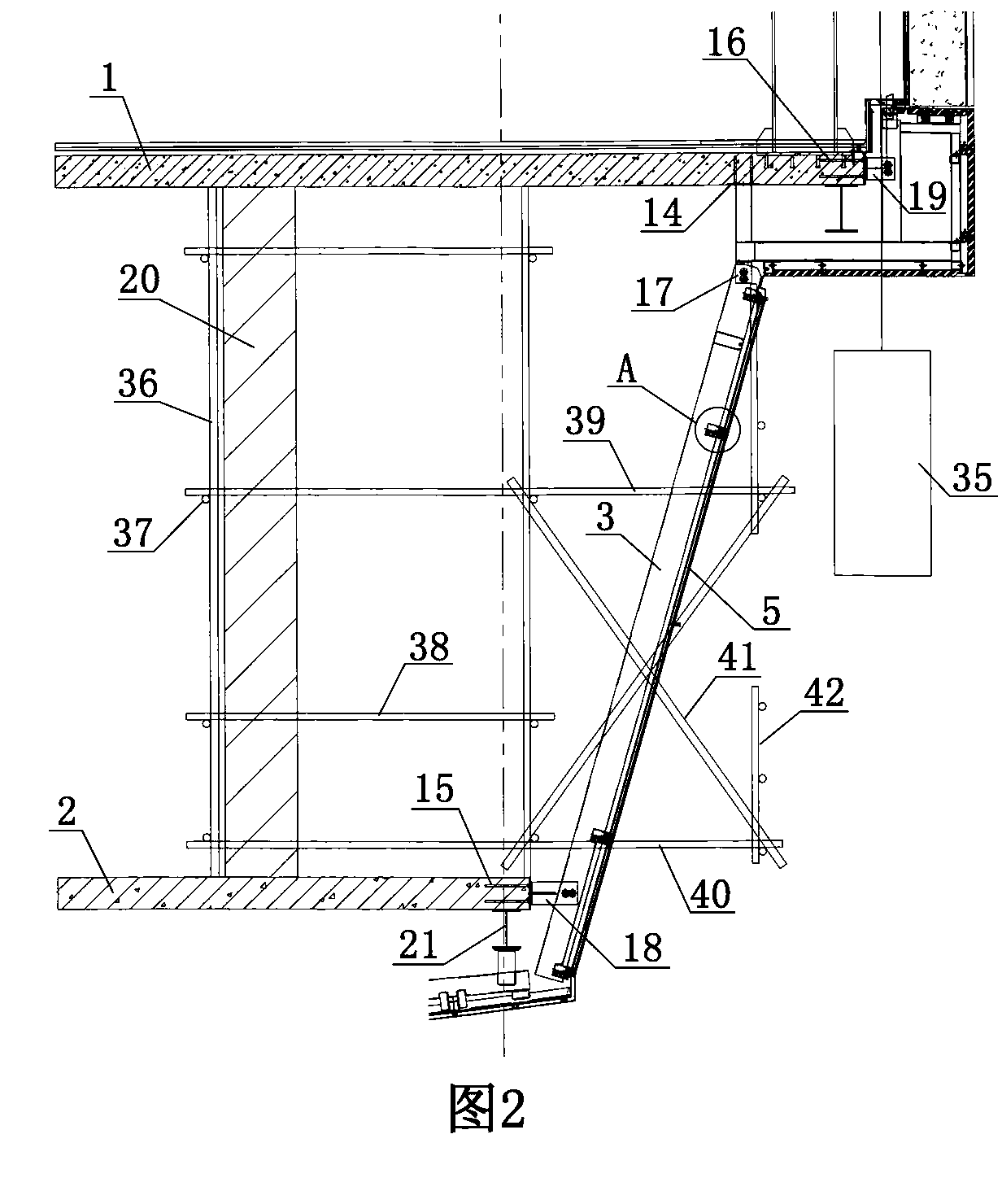

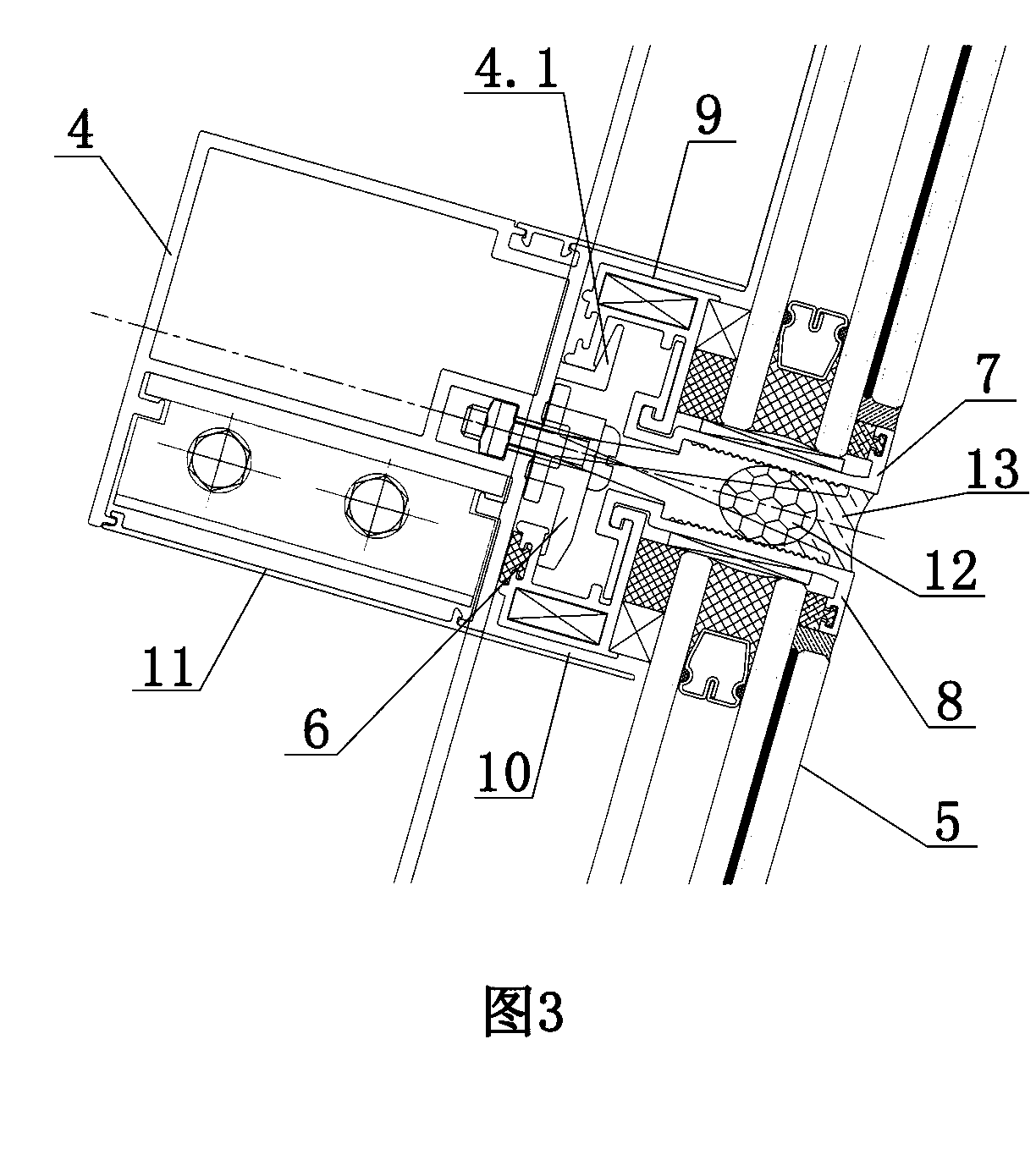

[0041] Examples see Figure 1 to Figure 5 As shown, this inclined curtain wall system includes a column 3 connected between the upper floor 1 and the lower floor 2, a horizontal frame 4 and a glazing assembly;

[0042] The lower surface of the outer end of the upper floor 1 is fixed with embedded parts I14, the outer side of the lower floor 2 is fixed with embedded parts II15, and the outer side of the upper floor 1 is fixed with embedded parts III16; Part III16 is respectively connected with connection angle code II18 and connection angle code III19, and the connection angle code is an angle steel with two oblong bolt holes on one side.

[0043] A steel frame connected by a steel frame beam 22, a steel frame column 23 and a steel frame longitudinal beam 24 is installed at the corner of the upper floor slab 1, the side of the steel frame column 23 is fixed with the connecting corner code III19, and the steel frame beam 22 is fixed on the pre- Below the embedded part I14, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com