Cosmetic packaging bottle and manufacturing process thereof

A production process and packaging bottle technology, which is applied in the field of cosmetic packaging bottles and new cosmetic bottle packaging bottles, can solve problems such as inability to control well, and achieve the effect of avoiding injection molding defects and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

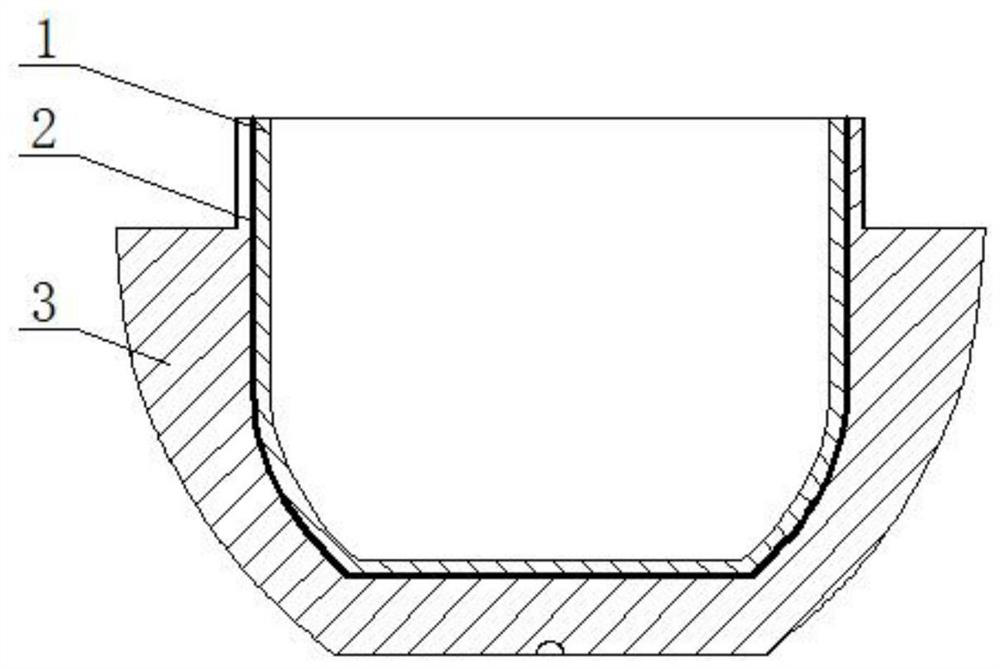

[0021] refer to figure 1 , the present invention comprises a bottle inner embryo 1, an electroplating layer 2 and a bottle shell 3, the electroplating layer 2 is electroplated on the outside of the bottle inner embryo 1, and a bottle shell 3 is injection-molded on the exterior of the electroplating layer 2, and the thickness of the bottom of the bottle shell 3 is greater than that of the bottom The thickness of the edge, the bottom center of the bottle shell 3 has an injection shrinkage port.

[0022] Specifically, the bottle inner embryo 1 is a hollow circular shell, and the bottle shell 3 is a hollow circular or hollow square shell.

[0023] The present invention also includes its manufacturing process, comprising the following steps:

[0024] Step 1: forming the inner embryo 1 of the raw material 1 by injection molding or casting;

[0025] Step 2: Electroplating the bottle inner embryo 1 to form an electroplating layer 2 on the outer surface of the bottle inner embryo 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com