Construction method of large-cross section loess tunnel cave entering shallow buried section

A technology for loess tunnels and construction methods, which is applied to tunnels, tunnel linings, and earthwork drilling and mining, and can solve problems such as complex construction, high cost, and long construction period, and achieve the effects of speeding up construction progress, improving economic benefits, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

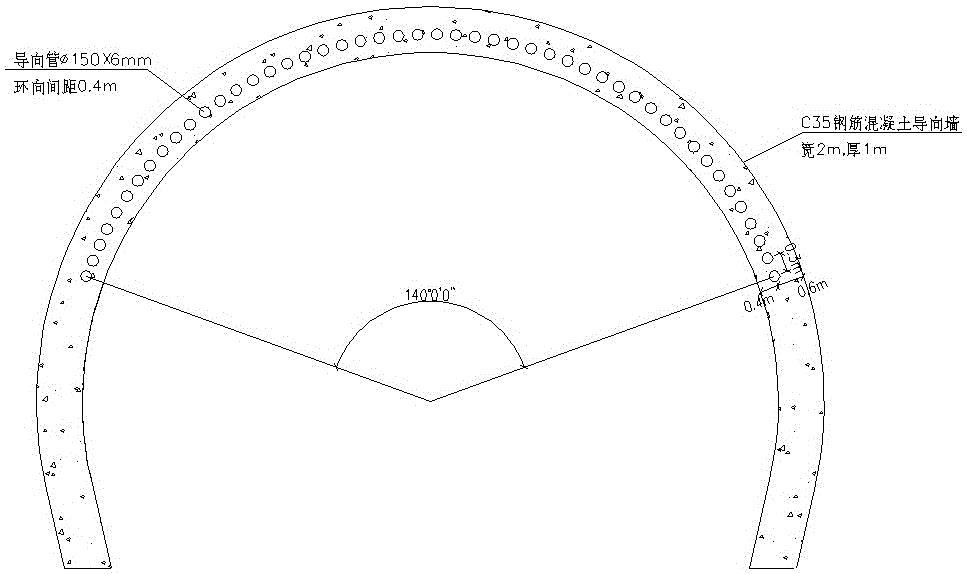

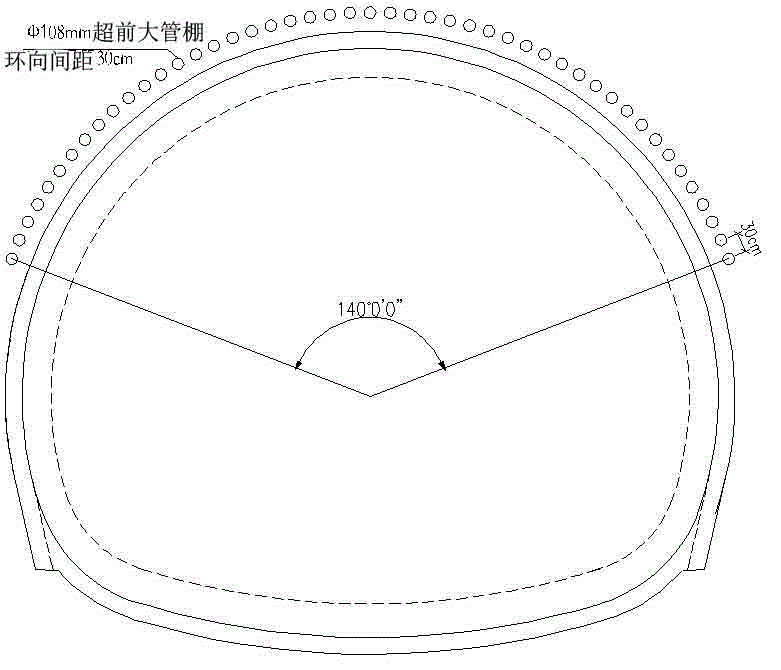

[0032] Example 1: During the construction of the technical scheme of the present invention, a large section loess tunnel entry shallow buried section of a passenger dedicated line in the western region (mileage DK204+702~DK204+752, buried depth 4~10m) was selected and successfully applied With this method, the main construction procedures are as attached Figure 1~8 Shown.

[0033] The present invention will be further described below in conjunction with the drawings and specific embodiments.

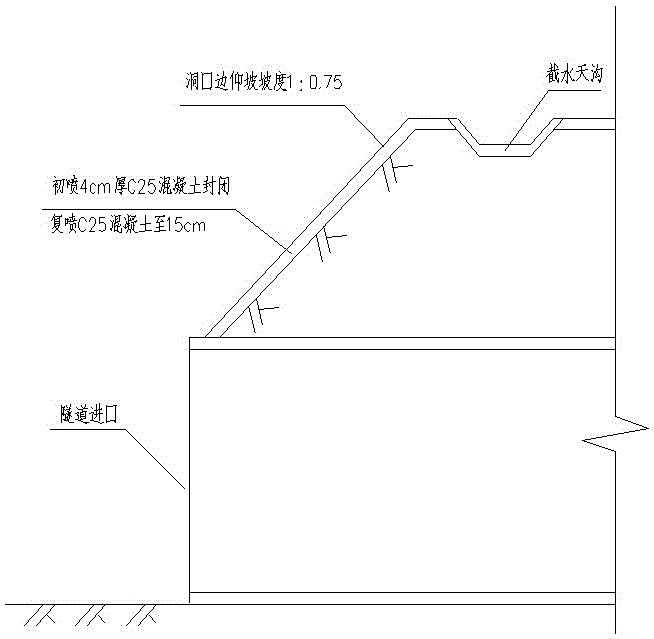

[0034] Step 1. Excavation protection on the side of the cave entrance. Before excavation, measure the edge line of the side slope excavation; make a cut-off gutter 5m away from the excavation line. The slope of the side of the cave entrance is excavated in layers from top to bottom according to the design, with a slope of 1:0.75. After the excavation of the side slope, the 4cm thick C25 concrete was first sprayed to seal it, and Ф22 mortar anchor rods were applied. The length is 3.5m, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com