Method for putting up steel pipe pile platform of abrupt slope bare rock

A steel pipe pile and platform technology, which is applied in bridge construction, erection/assembly of bridges, water conservancy projects, etc., can solve the problems of large amount of riprap, long transportation distance, high cost of caisson manufacturing, etc., and achieves a simple structure of the construction platform, Strengthen the rigidity and stability, the effect of convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

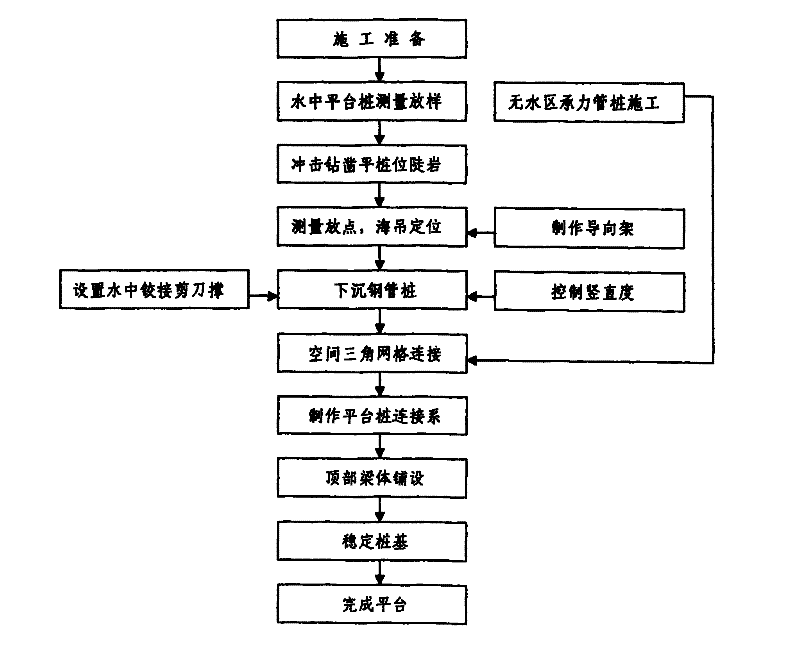

Method used

Image

Examples

Embodiment 1

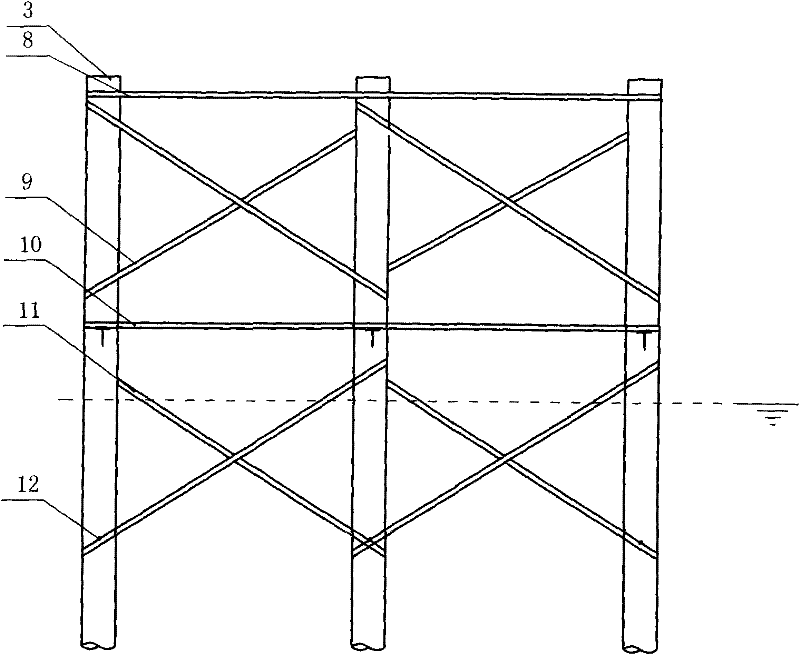

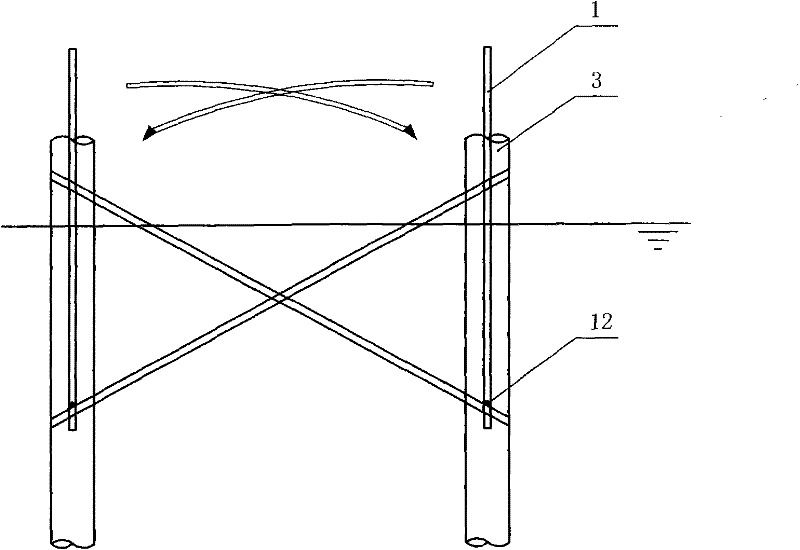

[0012] The steel pipe pile platform in water is composed of support piles, flat joints, scissors braces, top beams, longitudinal beams and platform top pavement. Among them, the platform surface is made of small steel or steel bars and wooden boards, which are laid on the top transverse and longitudinal beams; the top transverse and longitudinal beams are supported on steel pipe piles as the main load-bearing beam; Connection, the scissor brace is connected obliquely to ensure the overall stability and torsion resistance of the platform.

[0013] 1. Chisel flat steel pipe pile foundation

[0014] Connect two small construction transport ships with section steel, reserve drilling positions between the hulls, and set up temporary floating platforms in the water. The floating platform composed of construction ships is preliminarily anchored at the platform position. The surveyors accurately stake out the platform pile positions, determine the position of the steel pipe piles on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com