Method for building prestressed concrete through bowstring arch bridge

A technology of tied arch bridges and construction methods, applied in arch bridges, bridge construction, construction, etc., can solve problems such as restrictions on the transportation of rack-transporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

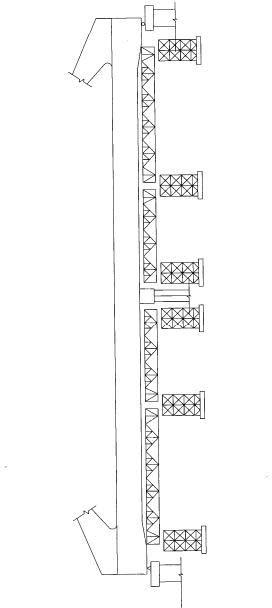

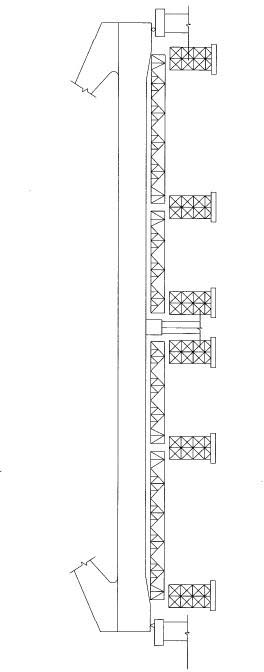

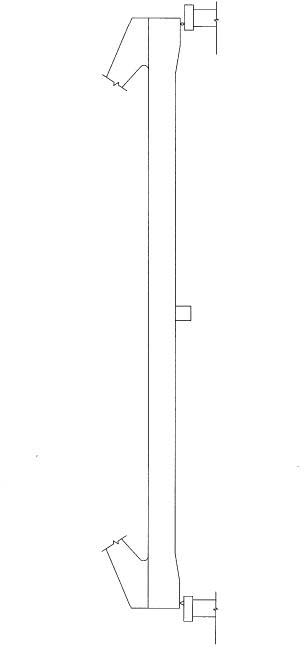

Image

Examples

Embodiment Construction

[0021] At both ends of the pre-installed tied arch bridge, permanent piers are built first, and temporary piers are erected in the middle span of the tied arch bridge. The structural form of the temporary piers needs to be compared and selected, and the stability is checked. The support must correspond to the position of the diaphragm of the box girder. After the construction of the temporary buttress in the mid-span is completed, the girder support and the door opening for passing the vehicle are erected, and the box girder of the main girder of the arch bridge and the 0.4-meter-high concrete arch foot are poured by conventional methods. The supports at the fixed end of the beam cannot be locked.

[0022] After the strength and elastic modulus of the box girder concrete of the main girder of the arch bridge reach more than 90% of the design value and not less than 10 days of age, the box girder of the main girder of the arch bridge is stretched in a vertical and symmetrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com