A manufacturing method of a double-curved fish-belly continuous box girder variable-section steel formwork

A production method and technology for steel formwork, which are applied in the directions of manufacturing tools, auxiliary welding equipment, welding equipment, etc., can solve the problems of difficulty in ensuring the construction quality of the overall smoothness of the appearance of the landscape bridge, low difficulty in production and assembly, and increased construction difficulty. To achieve the effect of improving the visual quality, fast construction speed and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0031] The manufacturing method of the double-curved fish-belly continuous box girder variable-section steel formwork designed by the present invention, the specific operation process is as follows:

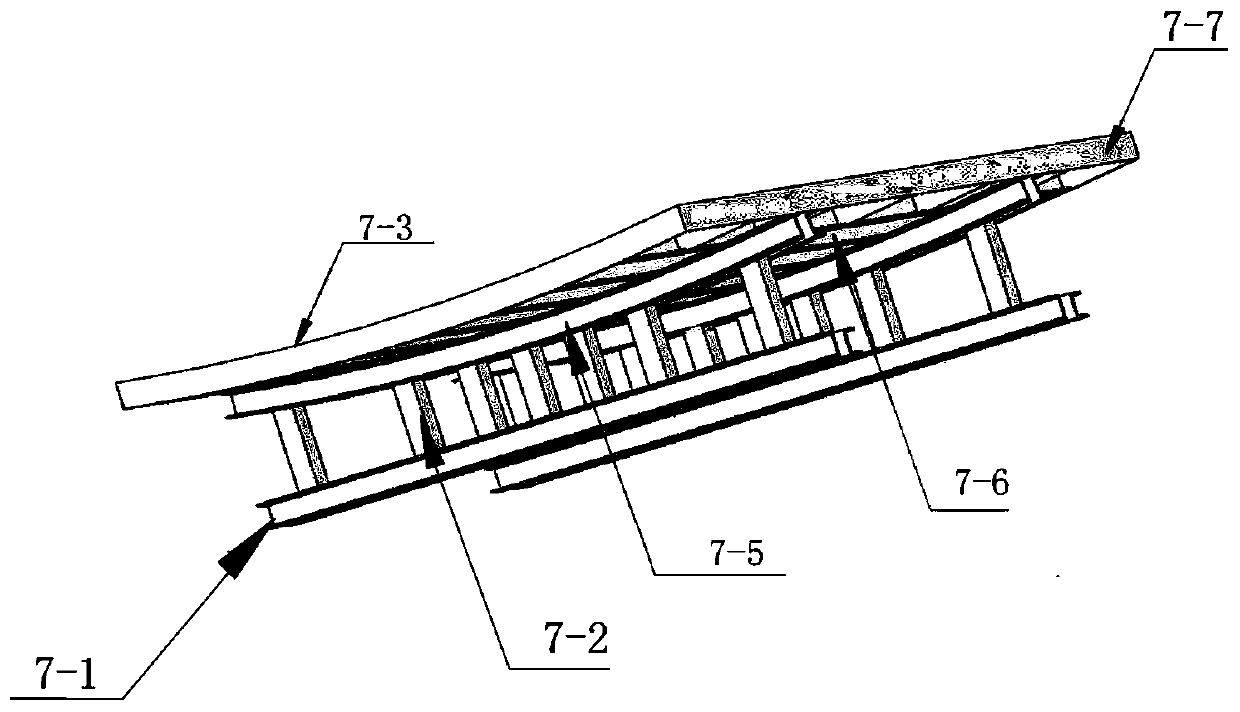

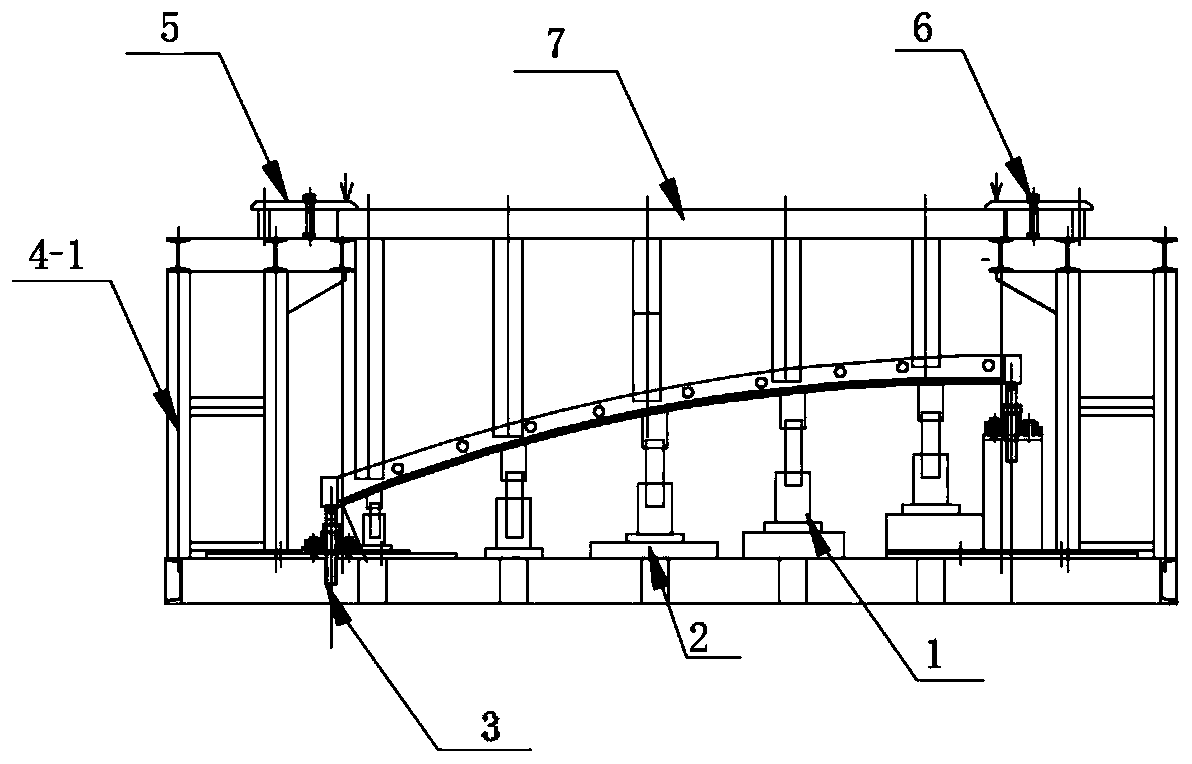

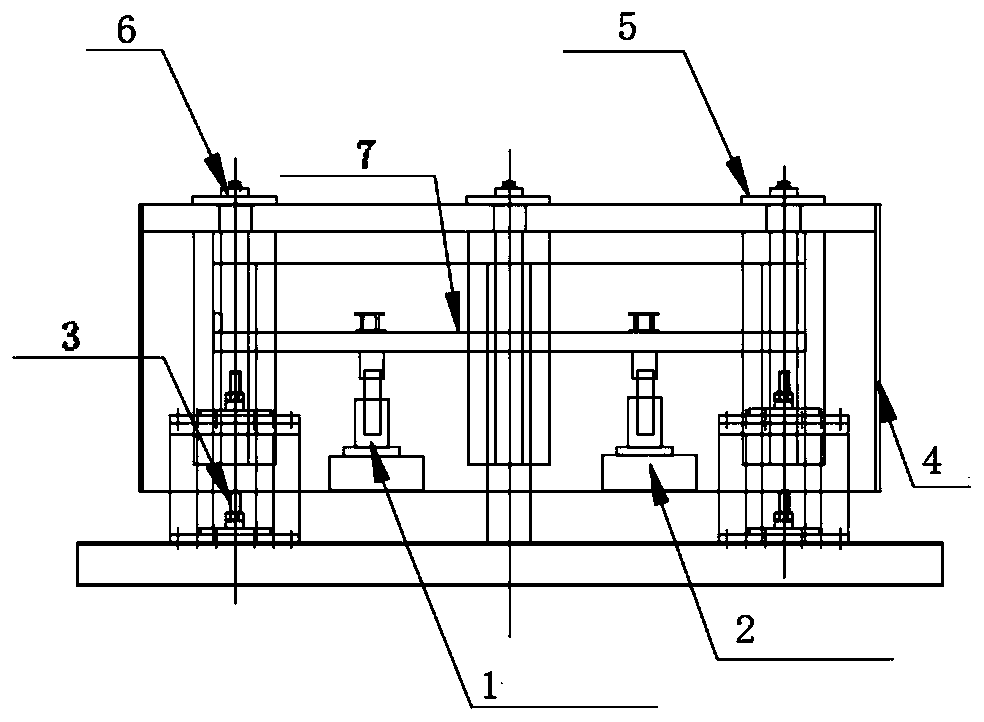

[0032] 1. First, use drawing software, CAD or BIM to carry out three-dimensional modeling, and then use total station and calipers to measure and collect the deviation data of the position of the wrong platform. Lofting technology, which divides the three-dimensional curved bottom mold into small unit templates of various specifications. On the one hand, the division is based on the requirement of designing variable cross-section arcs. The panels at positions with large radii are relatively large, and the panels at positions with small radii are divided into smaller pieces, taking into account the difficulty of splicing and fabrication; on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com