Composite nanofiber lithium battery diaphragm and making method thereof

A composite nanofiber and lithium battery diaphragm technology, which is applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as self-closing performance of thermal dimensional stability, potential safety hazards, and low ion conductivity. , achieving excellent thermal dimensional stability, good thermal dimensional stability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

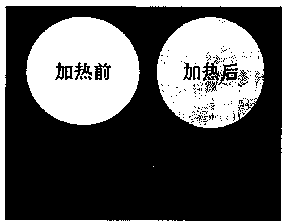

[0023] A meta-aramid-polyvinylidene fluoride composite nanofiber lithium battery diaphragm is composed of a layer of meta-aramid nanofiber film containing nanoparticles and a layer of low-melting polymer nanofiber film containing nanoparticles; The low-melting polymer is polyvinylidene fluoride with a melting point of 168-175°C; the nano-particle-containing meta-aramid nanofibers in the nano-particle-containing meta-aramid nanofiber membrane are interlaced and interlaced Point bonding and interconnection, the low-melting-point polymer nanofibers containing nanoparticles in the low-melting-point polymer nanofiber film containing nanoparticles are interlaced with each other and bonded and interconnected at the interlaced points. The nanofibers in the fiber membrane of the particles are interlaced with each other and bonded and interconnected at the interlaced points.

[0024] The above-mentioned preparation method of composite nanofiber lithium battery separator includes the follow...

Embodiment 2

[0029] A meta-aramid-polyurethane-meta-aramid composite nano-fiber lithium battery diaphragm consists of a layer of meta-aramid nano-fiber membrane containing nanoparticles, a layer of low-melting polymer nano-fiber membrane containing nanoparticles and one Layer of meta-aramid nanofiber film containing nanoparticles; the low-melting polymer is polyurethane with a melting point of 158-163°C; the nano-particle-containing meta-aramid nanofiber film The meta-aramid nanofibers of the particles are interlaced and bonded and interconnected at the interlacing points. The low-melting-point polymer nanofibers containing nano-particles in the low-melting-point polymer nanofiber film containing nanoparticles are interlaced and interlaced with each other. The interlaced points are bonded and interconnected, and the nanofibers in adjacent nanoparticle-containing fiber membranes are interlaced and bonded and interconnected at the interlaced points.

[0030] The above-mentioned preparation meth...

Embodiment 3

[0035] A meta-aramid-polyvinyl chloride / poly(vinylidene fluoride-hexafluoropropylene) composite nanofiber lithium battery separator, composed of a layer of meta-aramid nanofiber membrane containing nanoparticles and a layer of low Composite of melting point polymer nanofiber membrane; the low melting point polymer is polyvinyl chloride with a melting point of 165 to 175°C and poly(vinylidene fluoride-hexafluoropropylene) with a melting point of 138 to 160°C; the containing The nano-particle-containing meta-aramid nanofibers in the nano-particle meta-aramid nanofiber film are interlaced with each other and bonded and interconnected at the staggered points, and the nano-particle-containing low-melting polymer nanofiber film is The low-melting polymer nanofibers containing nanoparticles are interlaced with each other and bonded and interconnected at the interlaced points, and the nanofibers in adjacent nanoparticle-containing fiber membranes are interlaced with each other and bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com