Method for preparing nano fiber endless tow

A technology of nanofibers and filament bundles, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve problems such as loss, fiber scattering, and fiber loss, so as to avoid scattering and loss, improve production efficiency, The effect of efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

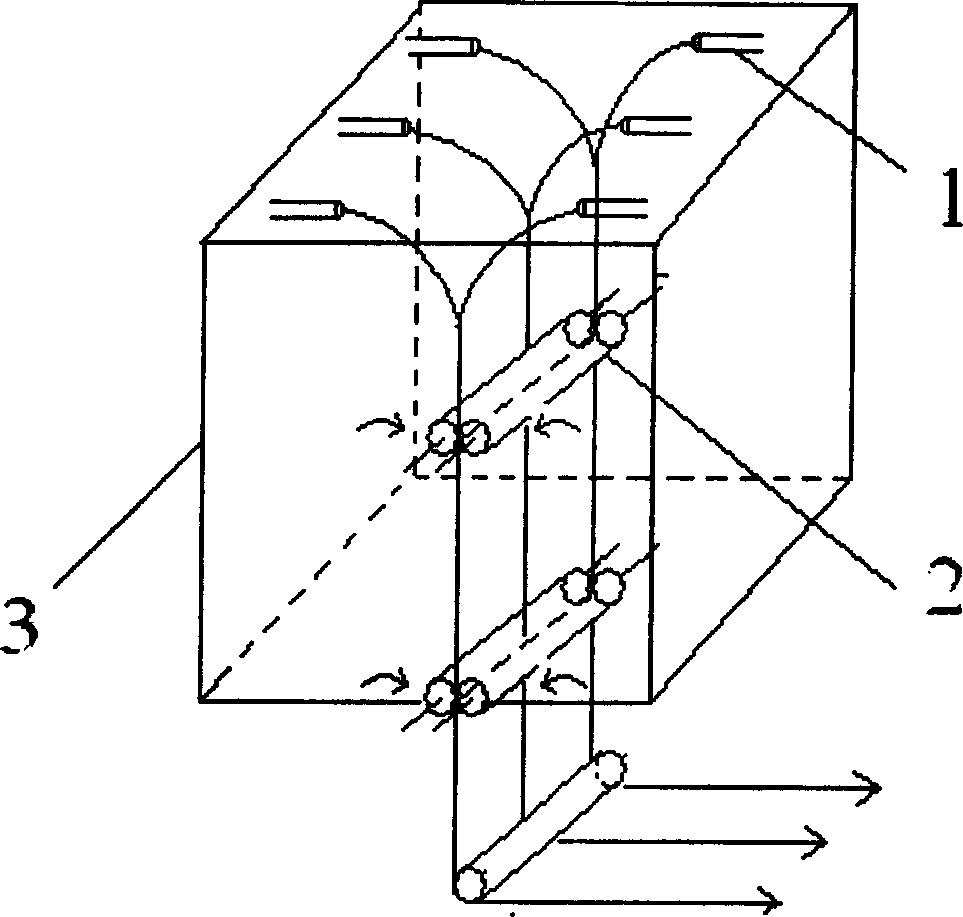

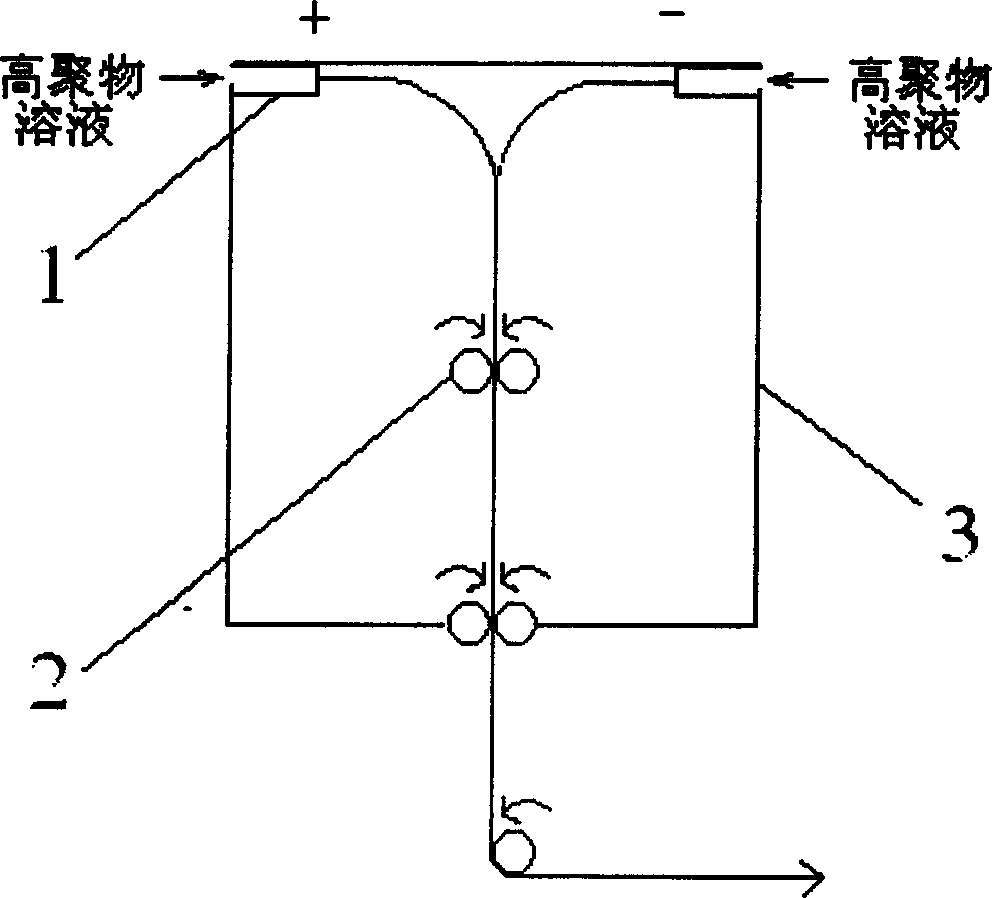

[0021] A method for preparing nanofiber filament bundles adopts a spinning box, two rows of electrospinning nozzles with opposite nozzles are placed in parallel at the same height on the top of the spinning box, and several sets of godet rolls are arranged in the middle of the spinning box Yes, the distance between the godet pair and the electrospinning nozzle facing the two rows of nozzles is equal. The specific preparation steps of a nanofiber filament bundle are as follows: (1) the high polymer solution is delivered to the electrospinning nozzle in the nanofiber filament bundle spinning box; (2) the electrospinning nozzle facing two rows of nozzles Apply a DC high voltage of 10KV-100KV with opposite polarity respectively; (3) The polymer solution at the top of the electrospinning nozzle is stretched and whipped under the action of the electric field force to form charged nanofibers, and the electrospinning nozzle with the opposite nozzle sprays The nanofibers produced have ...

Embodiment 1

[0024] Polyacrylonitrile PAN100g is dissolved in 1000mlN, in N-dimethylformamide, and this polymer solution is delivered to two rows of 100 electrospinning nozzles in the nanofiber filament bundle spinning box. The distance between each row of electrospinning nozzles in the spinning box is 5 cm, and the distance between two rows of electrospinning nozzles facing each other is 10 cm. Apply opposite polarity DC high voltage ±20kv to the electrospinning nozzles with two rows of nozzles facing each other, and the inner diameter of the electrospinning nozzles is 0.5mm. The speed at which the godet pulls the filament bundle is 3 cm / s. The nanofibers ejected from the top of the electrospinning nozzle are drawn by the godet roller to form filament bundles and are led out for collection.

Embodiment 2

[0026] Poly-L-lactic acid PLLA (viscosity average molecular weight 100,000) 100g is dissolved in 500ml acetone and 500ml N, in the mixed solvent of N-dimethylformamide, this polymer solution is delivered to nanofiber filament bundle spinning box There are 100 electrospinning nozzles in each of the two rows. The distance between the nozzles in each row of electrospinning nozzles is 30 cm, and the distance between two rows of electrospinning nozzles facing each other is 50 cm. Apply opposite polarity DC high voltage ±10kv to the electrospinning nozzles with two rows of nozzles facing each other, and the inner diameter of the electrospinning nozzles is 0.2mm. The speed at which the godet pulls the filament bundle is 6 cm / s. The nanofibers ejected from the top of the electrospinning nozzle are drawn by the godet roller to form filament bundles and are led out for collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com