Preparation method of aminated nanofiber membrane with high specific surface area

A nanofiber membrane, high specific surface area technology, applied in chemical instruments and methods, fiber processing, inorganic chemistry, etc., can solve problems such as loss of function, and achieve good adsorption, low cost, and easy large-scale production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

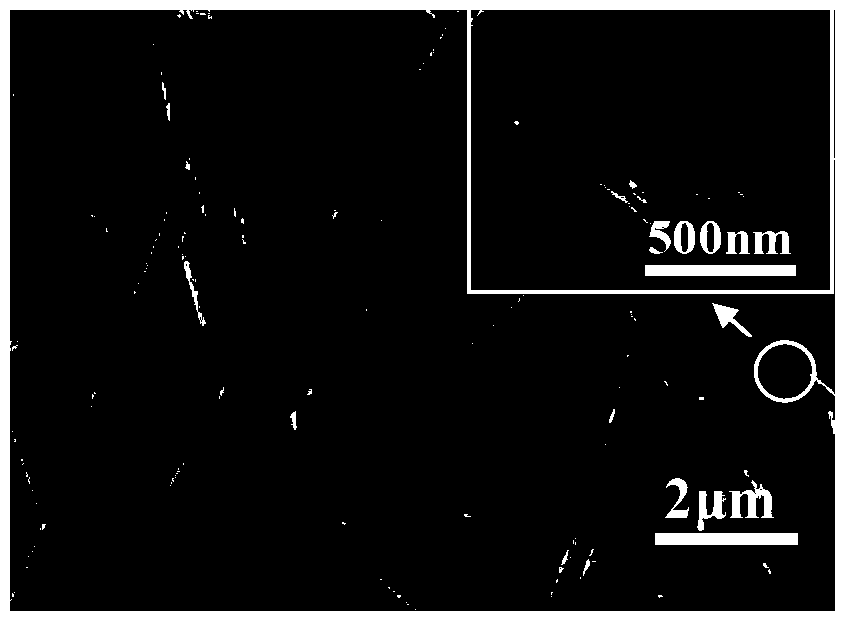

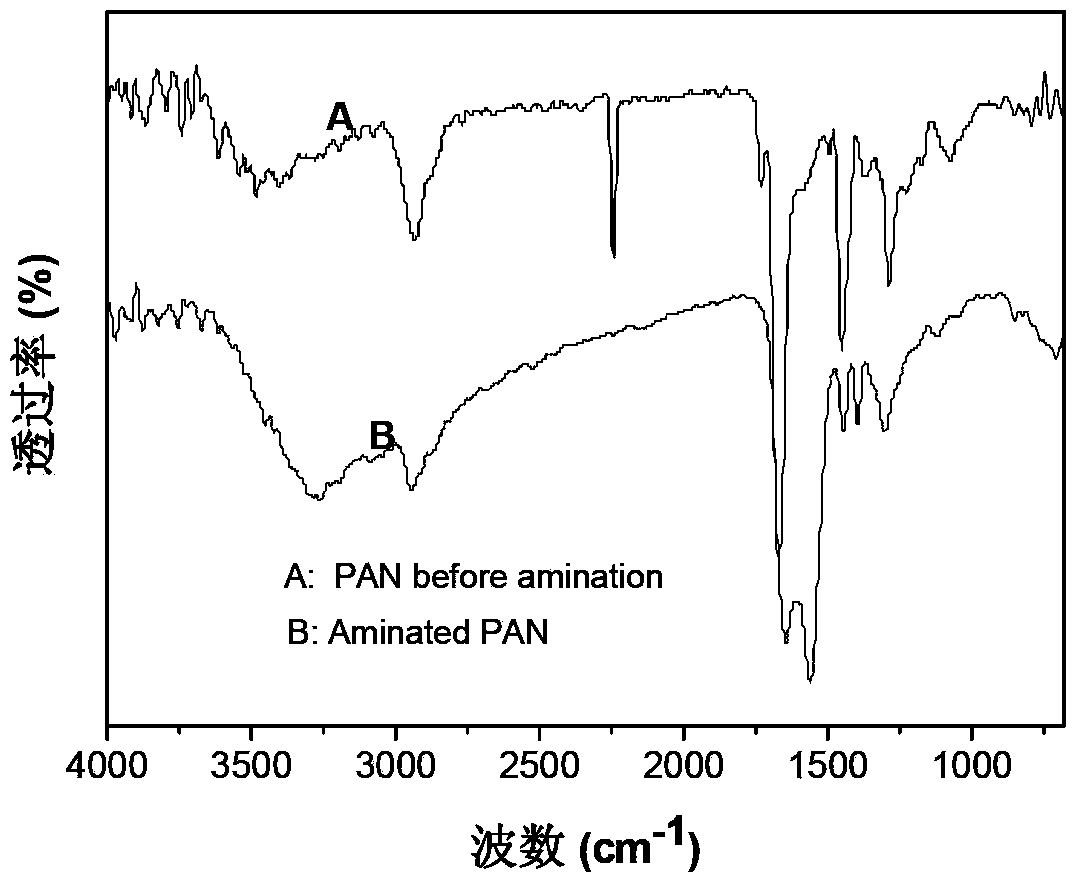

[0027] (1) Dissolve 10g of polyacrylonitrile PAN in 90g of N,N'-dimethylformamide DMF, then add 25g of poly-N-vinylpyrrolidone PVP, and stir at 60°C for 48 hours to obtain a uniform, Transparent electrospinning solution; the spinning solution is added to the container, extruded by a micro-injection pump, the nozzle is connected to a high-voltage positive electrode, the electrospinning parameters are voltage 25KV, nozzle aperture 1.5mm, solution flow rate 1.5ml / h, environment The temperature was 25°C, the air relative humidity was 35%, and electrospinning was performed. The obtained PAN-PVP composite nanofibers had an average diameter of 500 nm, a deposition thickness of 100 μm, and a porosity of 93%.

[0028] (2) Soak the PAN-PVP composite nanofiber membrane obtained in (1) into deionized water, adjust pH=5.0 with HCl, soak at 95°C for 48h, take out the membrane, wash it with deionized water, and dry Dry to obtain a nanofibrous membrane with a porous, micro-nano structure, tes...

Embodiment 2

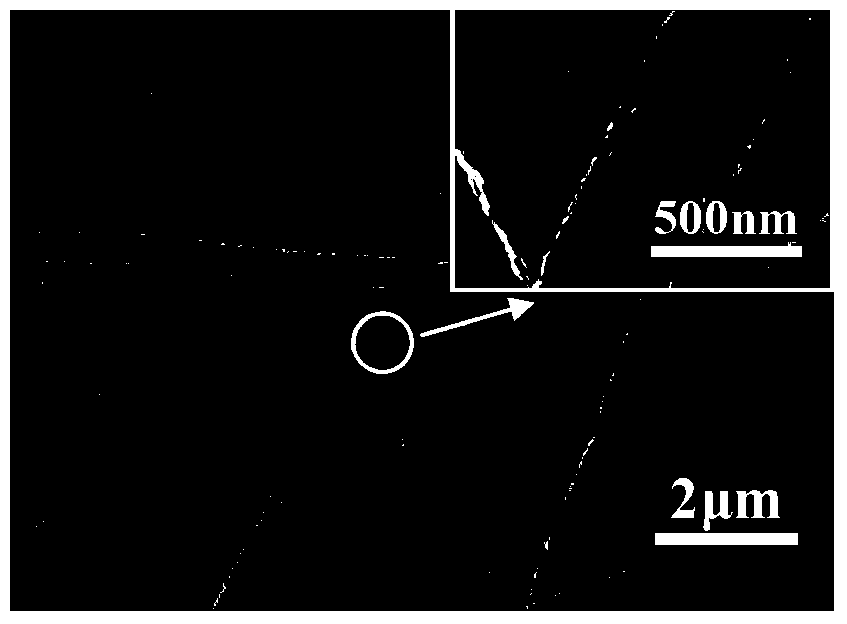

[0032] (1) Dissolve 20g polyacrylonitrile PAN in 70g N,N'-dimethylformamide DMF, then add 10g sodium bicarbonate NaHCO 3 , stirred at 50°C for 24 hours to obtain a uniform electrospinning solution with a concentration of 30%. Add the spinning solution to the container and extrude it under the control of a micro-injection pump. The nozzle is connected to a high-voltage positive electrode. , the nozzle aperture is 1.5mm, the solution flow rate is 1.5ml / h, the ambient temperature is 25°C, and the relative air humidity is 35%. Electrospinning is carried out, and the obtained PAN-NaHCO 3 The composite nanofibers have an average diameter of 450 nm, a deposition thickness of 100 μm, and a porosity of 90%.

[0033] (2) The PAN-NaHCO obtained in (1) 3 Soak the composite nanofiber membrane in deionized water, adjust the pH=3.0 with HCl, soak at 65°C for 24 hours, take out the membrane, wash it with deionized water, and dry it to obtain a nanofiber membrane with a porous, micro-nano str...

Embodiment 3

[0037] (1) Dissolve 10g of polyacrylonitrile PAN in 80g of N,N'-dimethylformamide DMF, then add 20g of ethylene oxide PEO, and stir at 60°C for 48h to obtain a uniform and transparent electrospun electrospun with a concentration of 27.3%. Silk solution: Add the spinning solution to the container, and extrude it under the control of a micro-injection pump. The nozzle is connected to a high-voltage positive electrode. The electrospinning parameters are voltage 25KV, nozzle aperture 1.5mm, solution flow rate 1.5ml / h, and ambient temperature 25°C. The relative air humidity was 35%, and electrospinning was performed. The average diameter of the obtained PAN-PEO composite nanofibers was 600nm, the deposition thickness was 100μm, and the porosity was 90%.

[0038] (2) Soak the PAN-PEO composite nanofiber membrane obtained in (1) into deionized water, adjust pH=5.0 with HCl, soak at 90°C for 48h, take out the membrane, wash it with deionized water, and dry Dry to obtain a nanofibrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com