Field-responsive superparamagnetic composite nanofibers and methods of use thereof

a composite nanofiber, field-responsive technology, applied in the field of field-responsive composite nanofibers, can solve the problems of inability to achieve superparamagnetic properties, 100 nm, and inability to produce magnetic composite nanofibers (100 nm),

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Composite Nanofibers Containing Magnetite Nanoparticles

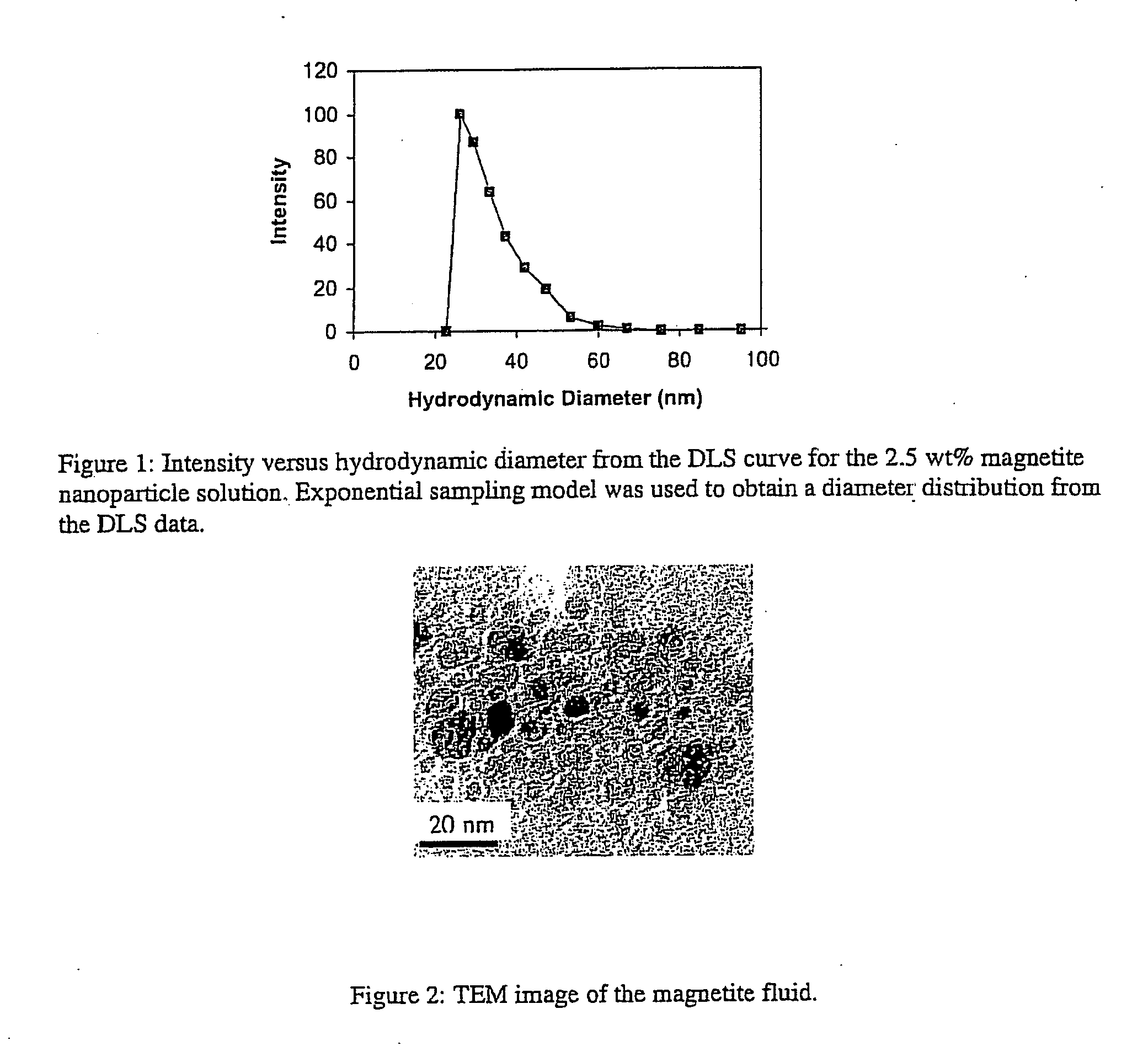

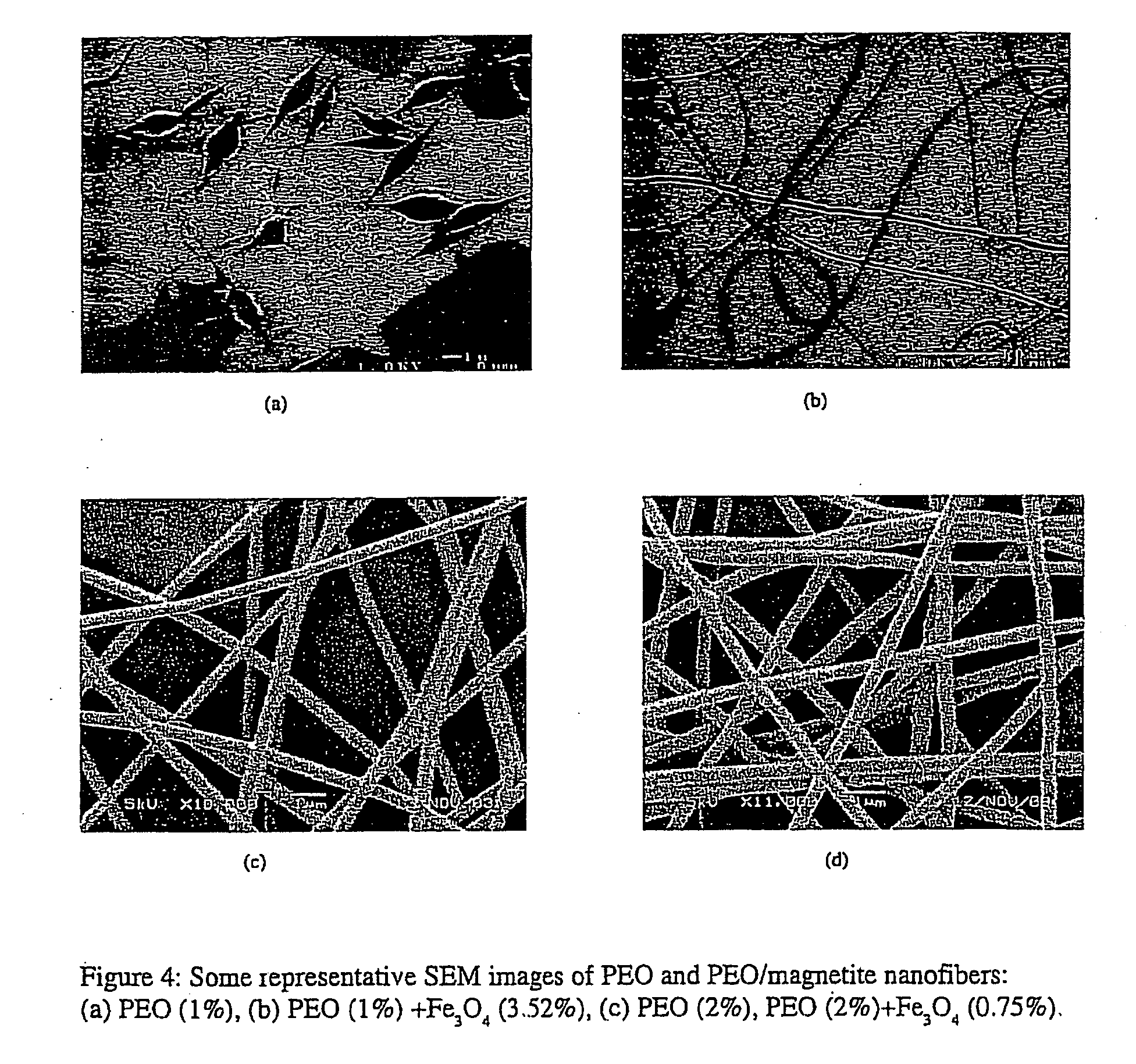

[0099] The size distribution of the magnetite nanoparticles was determined by DLS (FIG. 1), and corresponded to an average hydrodynamic diameter of 25 nm. An analysis of TEM images of the as-synthesized magnetite nanoparticles (FIG. 2) indicated an average core size, assuming a log normal distribution, of 7.5±2.9 nm. Only the magnetite cores were visible in TEM measurements, as the polymer coatings were of low contrast, and could not be discerned in these images. The difference between the average hydrodynamic diameter and core size yielded a thickness of about 9 nm for the polymer shell.

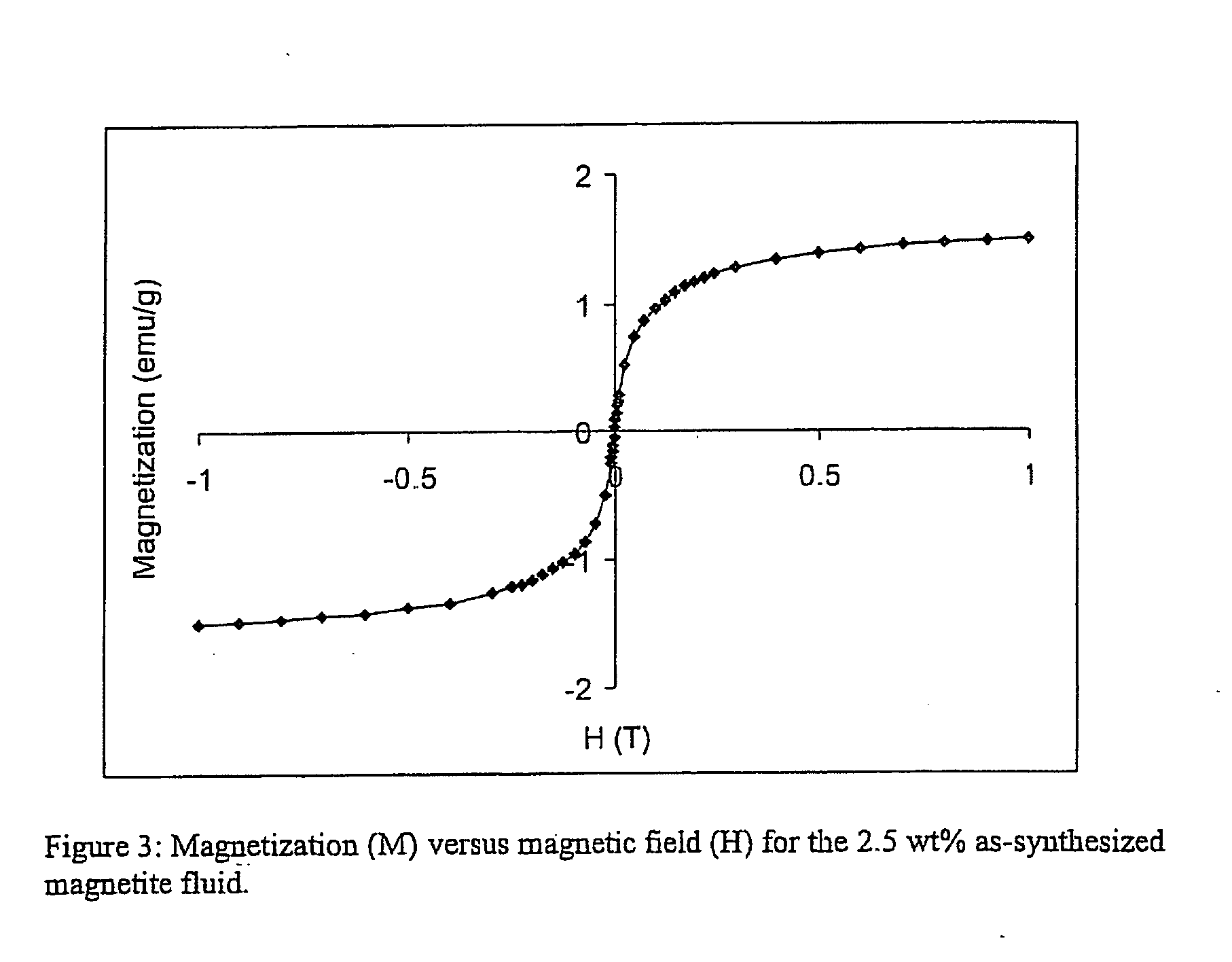

[0100] The dependence of the magnetization, M, of the magnetite fluid on the applied magnetic field in the SQUID tests is shown in FIG. 3. The magnetite nanoparticle suspension exhibited superparamagnetic behavior in that there was zero remnant magnetization at zero applied field. The saturation magnetization was approximately 0.5...

example 3

Electrospinning Effects on Nanofiber Characteristics

[0105] In order to further characterize PEO / magnetite and PVA / magnetite nanofibers, transmission electron microscropy was utilized to visualize the fibers (FIG. 6). The weight percentages of magnetite nanoparticles within the fibers were 28%, and 8% for PEO / magnetite and PVA / magnetite nanofibers, respectively. The relatively large size of the PEO fiber and high content of nanoparticles within the fiber made it difficult to focus the TEM pictures, but the contour of the alignment of the nanoparticles into columns along the fiber axis direction was readily visible. For the PVA / magnetite fiber, the images were clearer, and demonstrated magnetite nanoparticle alignment in columns parallel to the fiber axis direction within the fiber.

[0106] Magnetite nanoparticles can form chains in solution owing to magnetic coupling effects between particles. The number of nanoparticles, n0. in a chain in the fluid, at zero external field, can be es...

example 4

Structural Characterization of the Composite Nanofibers Comprising Magnetite Nanoparticles

[0109] The elastic modulus of the fibers was evaluated using an AFM indentation technique according to the following formula [Vanlandingham M. R., et al., J. Adhesion 1997; 64: 31-57; Sneddon J. N., Int. J. Engng. Sci. 1965; 3: 47-56; Pharr G. M., et al., J. Mater. Res. 1992; 7: 613-617; Vanlandingham M. R., et al., Composites Part A1999; 30:75-83; Drechsler D., et al., Appl. Phys. A 1998; 66: S825-S829]: S=ⅆPⅆΔ Zi❘Pmax=2E*(Aπ)12(3)

[0110] Here, S was the slope of the unloading curve at Pmax, P was the applied load, A was the contact area, ΔZi is the indentation depth, and E* was the effective Young's modulus of the contact as defined by 1E*=1-vs2Es+1-vt2Et(4)

[0111] In equation (4), Es and Et were the elastic moduli, and vσ and vt the Poisson ratios of the sample and the tip, respectively. A diamond tip was used, with asymmetric pyramidal geometry; indent size was characterized by the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Nèel relaxation time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com