Method for preparing NCC/CS/PVA composite nano-membrane

A nano-crystal, polyvinyl alcohol technology, applied in spinning solution preparation, textiles and papermaking, non-woven fabrics, etc., to achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

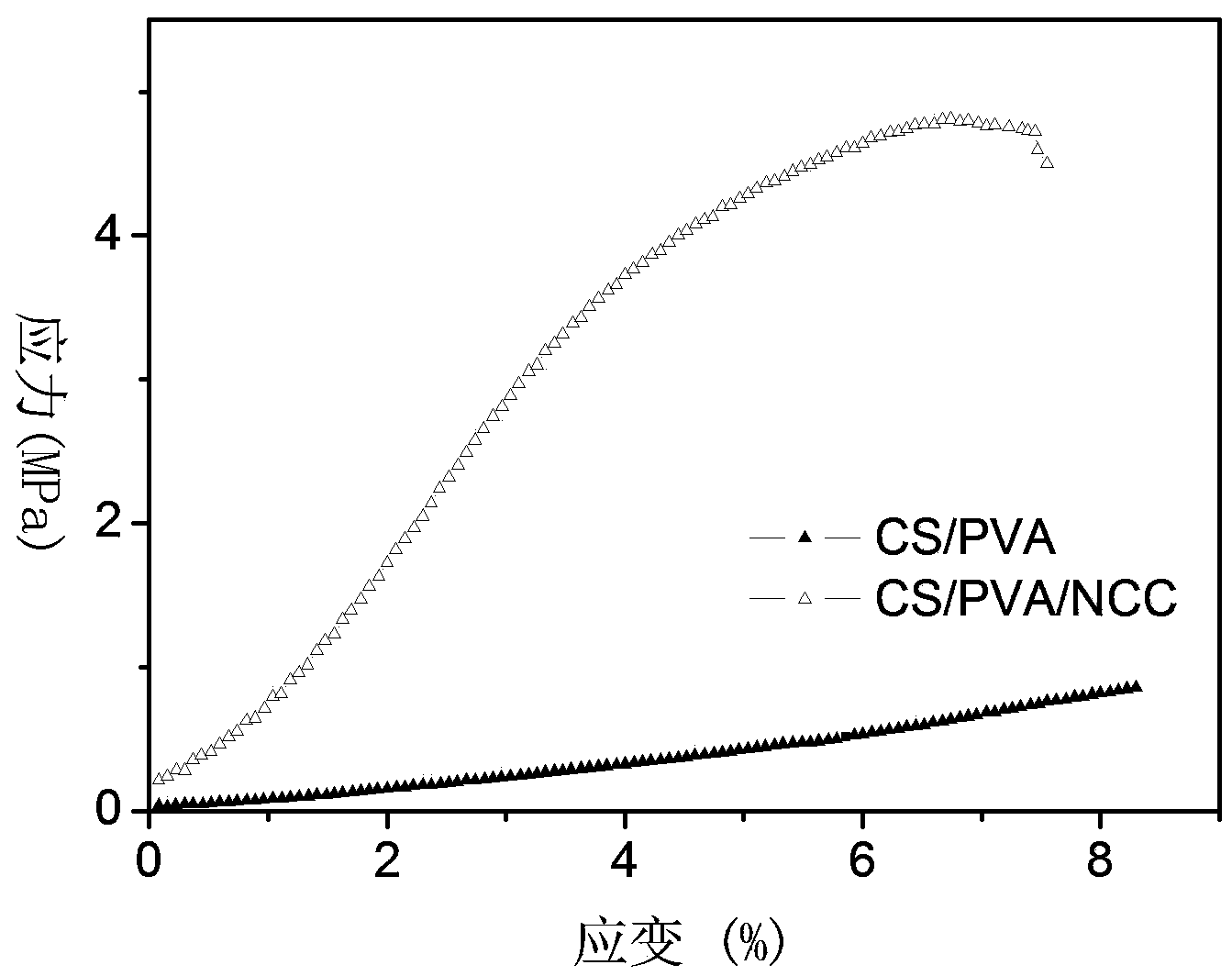

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of nanocrystalline cellulose: Weigh 5 g of microcrystalline cellulose (MCC) into 50 ml of deionized water. The MCC mixture was placed in an ice-water bath, 87 g of concentrated sulfuric acid was added dropwise, heated and stirred at 44 °C for 2 h, and then 1500 ml of deionized water was quickly added to terminate the reaction. The mixture was left to stand for 3 days, during which time the supernatant was poured off 3 times, and an equal amount of deionized water was added each time to let it stand again. The resulting final suspension was centrifuged repeatedly 5 times (5 min, 10000 rpm). The centrifuged mixed solution was dialyzed until the pH of the solution outside the dialysis bag was close to 7. Pour out the solution in the dialysis bag, sonicate for 20 min, and finally lyophilize into powder;

[0023] (2) Prepare a 3wt% chitosan solution with 1 mol / L acetic acid;

[0024] (3) Mix the nano-microcrystalline cellulose prepared in step (1) with the...

Embodiment 2

[0031] (1) Preparation of nanocrystalline cellulose: Weigh 5 g of microcrystalline cellulose (MCC) into 50 ml of deionized water. The MCC mixture was placed in an ice-water bath, 87 g of concentrated sulfuric acid was added dropwise, heated and stirred at 44 °C for 2 h, and then 1500 ml of deionized water was quickly added to terminate the reaction. The mixture was left to stand for 3 days, during which time the supernatant was poured off 3 times, and an equal amount of deionized water was added each time to let it stand again. The resulting final suspension was centrifuged repeatedly 5 times (5 min, 10000 rpm). The centrifuged mixed solution was dialyzed until the pH of the solution outside the dialysis bag was close to 7. Pour out the solution in the dialysis bag, sonicate for 20 minutes, and finally lyophilize into powder;

[0032] (2) Prepare a 3wt% chitosan solution with 1 mol / L acetic acid;

[0033] (3) Mix the nano-microcrystalline cellulose prepared in step (1) with...

Embodiment 3

[0041] (1) Preparation of nanocrystalline cellulose: Weigh 5 g of microcrystalline cellulose (MCC) into 50 ml of deionized water. The MCC mixture was placed in an ice-water bath, 87 g of concentrated sulfuric acid was added dropwise, heated and stirred at 44 °C for 2 h, and then 1500 ml of deionized water was quickly added to terminate the reaction. The mixture was left to stand for 3 days, during which time the supernatant was poured off 3 times, and an equal amount of deionized water was added each time to let it stand again. The resulting final suspension was centrifuged repeatedly 5 times (5 min, 10000 rpm). The centrifuged mixed solution was dialyzed until the pH of the solution outside the dialysis bag was close to 7. Pour out the solution in the dialysis bag, sonicate for 20 min, and finally lyophilize into powder;

[0042] (2) Prepare a 3wt% chitosan solution with 1 mol / L acetic acid;

[0043] (3) Mix the nanocrystalline cellulose prepared in step (1) with the chito...

PUM

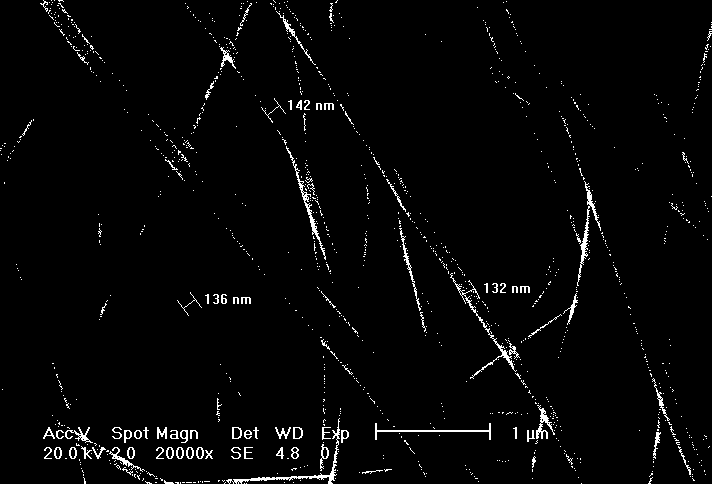

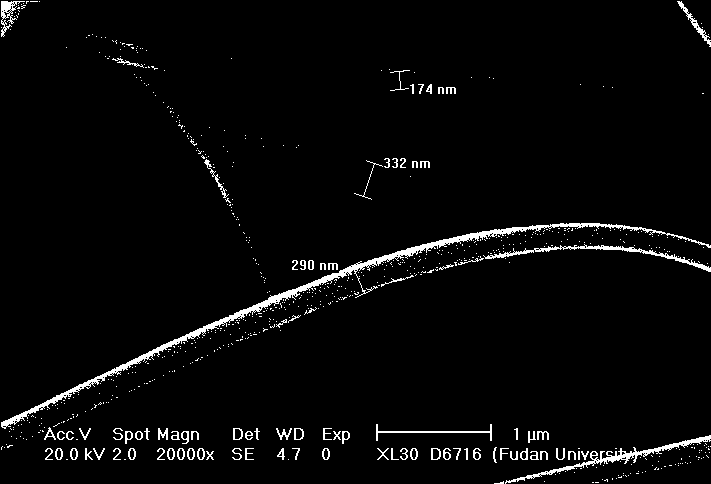

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com