ZIF-8/poly(vinyl alcohol) (PVA) composite nanofiber membrane as well as preparation method and application thereof

A composite nanofiber, ZIF-8 technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., to achieve the effects of reducing loss, easy recycling, and easy reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

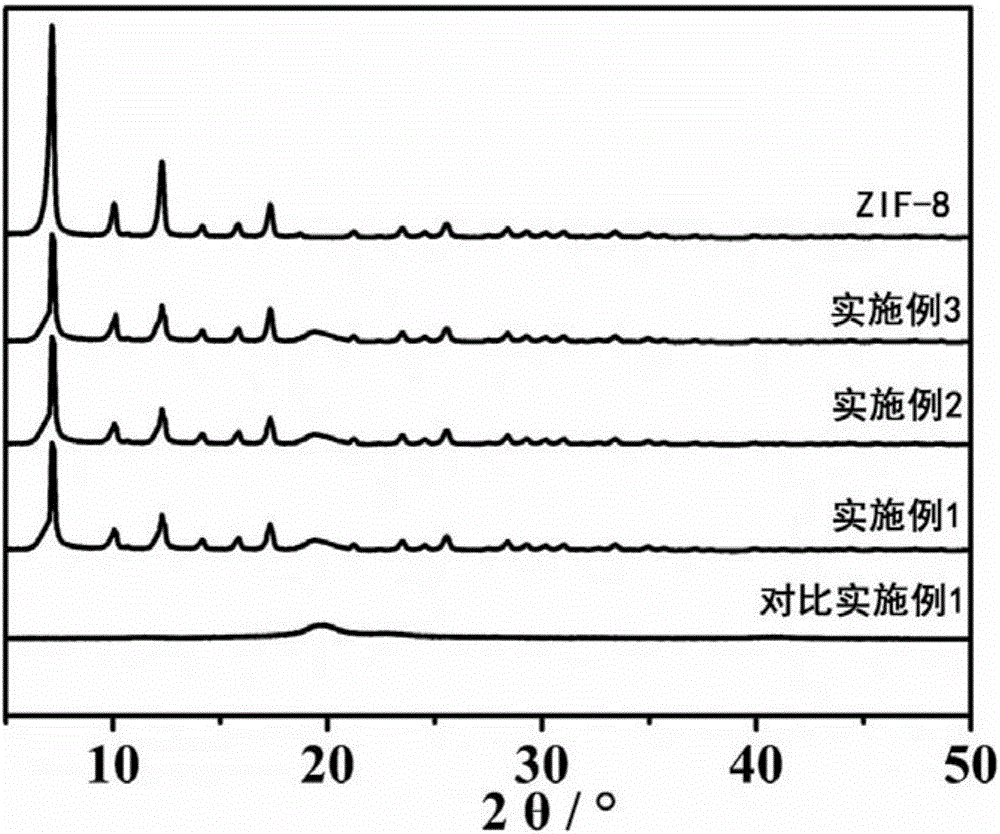

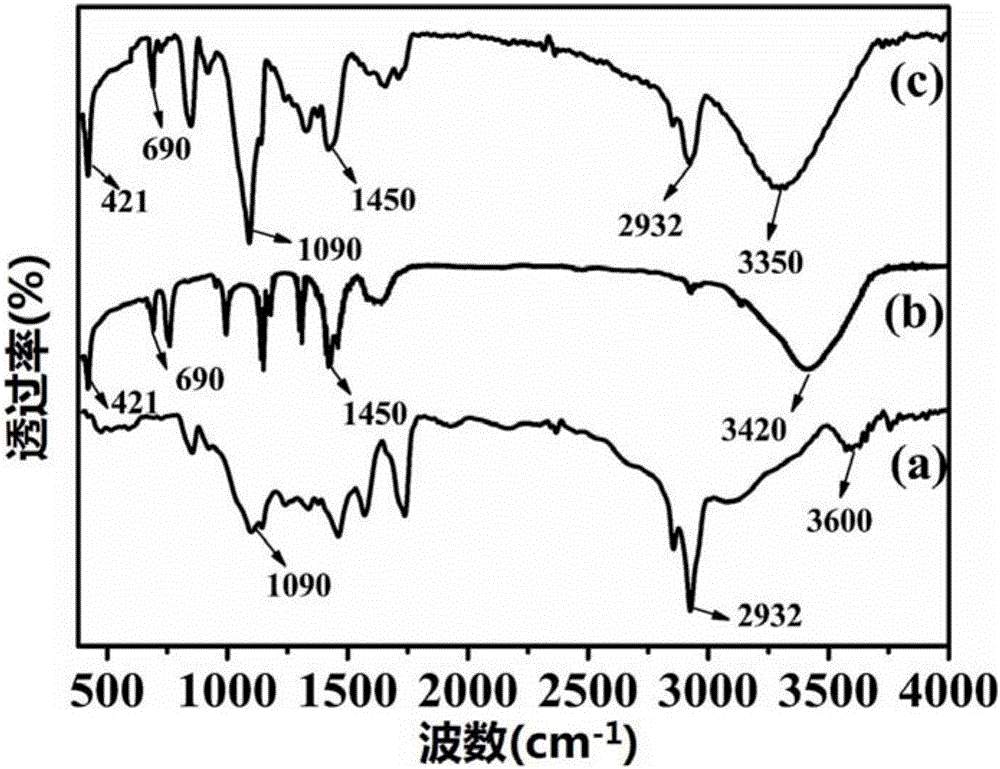

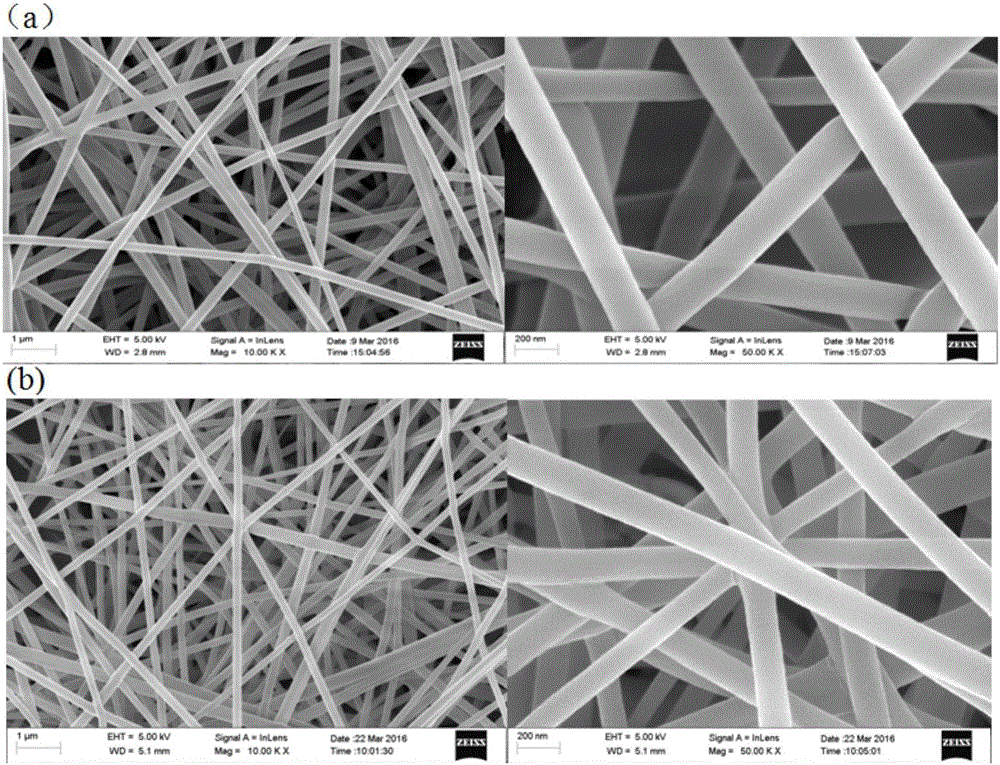

[0037] Embodiment 1: Preparation of 3wt%ZIF-8 / PVA porous nanofiber membrane

[0038] 200mL methanol solution containing 2.6g zinc nitrate hexahydrate and 200mL methanol solution containing 6.0g 2-methylimidazole were magnetically stirred and mixed at room temperature for 20h at room temperature, and the stirring speed was 1000rpm to prepare ZIF-8 nanoparticles, which were centrifuged at 5000rpm for 20min and used After washing with methanol, the obtained nanocrystals were vacuum-dried at 40° C. for 24 hours to obtain ZIF-8 nanoparticles.

[0039]Get 0.036g of the obtained ZIF-8 nanoparticles and mix them with 1.2g polyvinyl alcohol (PVA), then dissolve them in 18.764g deionized water, stir on a magnetic stirrer for 20min to fully swell, then heat and stir in a water bath at 80°C for 2h, the stirring speed 350rpm. Cool to room temperature to obtain a uniformly dispersed spinning solution.

[0040] The resulting electrospinning solution was placed in a 10mL syringe for electro...

Embodiment 2

[0041] Embodiment 2: Preparation of 1wt%ZIF-8 / PVA porous nanofiber membrane

[0042] A 200mL methanol solution containing 2.933g zinc nitrate hexahydrate and a 200mL methanol solution containing 6.489g 2-methylimidazole were magnetically stirred and mixed at room temperature for 22 hours at a stirring speed of 1100rpm to obtain ZIF-8 nanoparticles, centrifuged at 7000rpm for 15min and used After washing with methanol, the obtained nanocrystals were dried in vacuum at 50° C. for 20 h to obtain ZIF-8 nanoparticles.

[0043] Get 0.014g of the obtained ZIF-8 nanoparticles and mix them with 1.4g polyvinyl alcohol (PVA) and then dissolve them in 18.596g deionized water, stir on a magnetic stirrer for 30min to fully swell, then heat and stir in a water bath at 85°C for 2.5h, and stir The speed is 370rpm. Cool to room temperature to obtain a uniformly dispersed spinning solution.

[0044] The resulting electrospinning solution was placed in a 10mL syringe for electrospinning, the sp...

Embodiment 3

[0045] Embodiment 3: Preparation of 2wt% ZIF-8 / PVA porous nanofibrous membrane

[0046] 200mL methanol solution containing 3.4g zinc nitrate hexahydrate and 200mL methanol solution containing 7.0g 2-methylimidazole were magnetically stirred and mixed at room temperature for 24h at room temperature, and the stirring speed was 1200rpm to obtain ZIF-8 nanoparticles. Centrifuge at 8000rpm for 10min and use methanol After washing, the obtained nanocrystals were vacuum-dried at 60° C. for 12 hours to obtain ZIF-8 nanoparticles.

[0047] Get 0.032g of the obtained ZIF-8 nanoparticles and mix them with 1.6g polyvinyl alcohol (PVA) and then dissolve them in 18.368g deionized water, stir on a magnetic stirrer for 40min to fully swell, then heat and stir in a water bath at 90°C for 3h, the stirring speed 400rpm. Cool to room temperature to obtain a uniformly dispersed spinning solution.

[0048] The resulting electrospinning solution was placed in a 10mL syringe for electrospinning, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com