Preparation method of electric spinning-based composite nano fiber material for filters

A technology of composite nanofibers and electrospun nanofibers, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problem that the overall quality of the product cannot be guaranteed, it is difficult to detect and ensure the uniformity of nanofibers, and the continuity of spinning It is difficult to guarantee the stability of the spinning rate and other problems, and achieve the effects of low manufacturing cost, small increase in filtration resistance, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

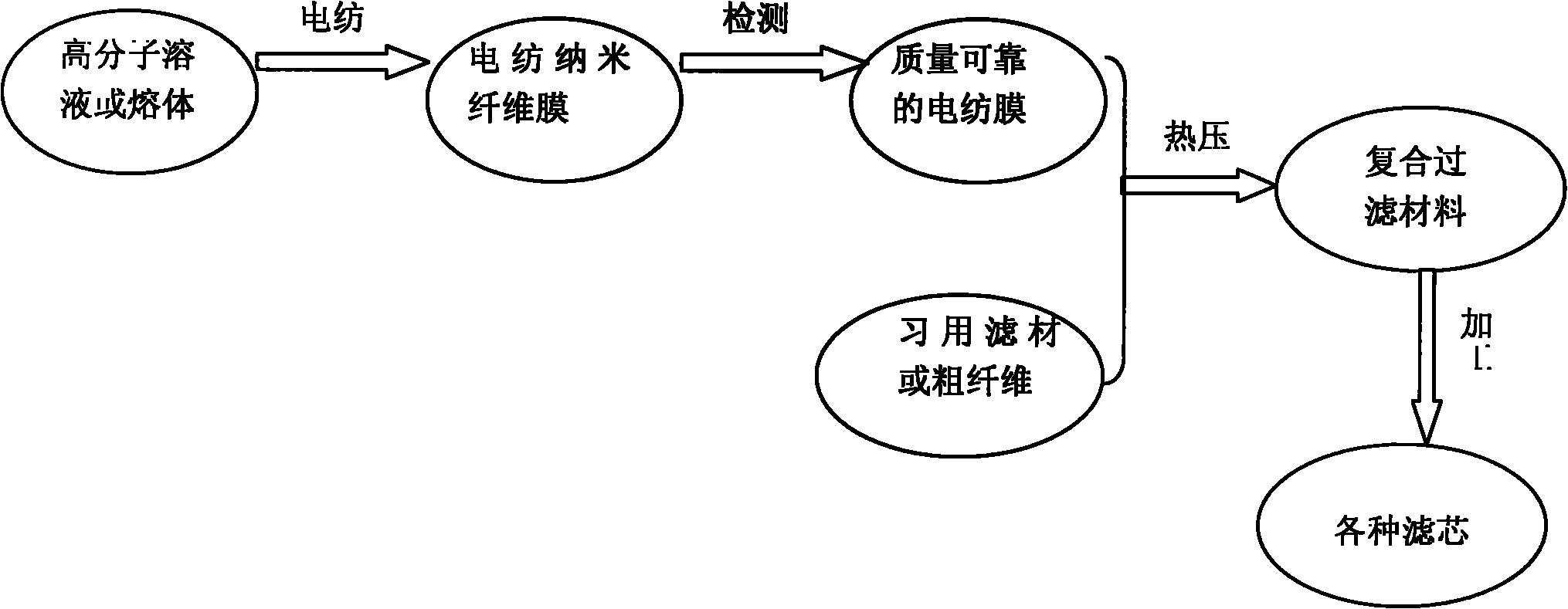

Method used

Image

Examples

Embodiment 1

[0024] A certain quality of polyester chips (PET) is dissolved in trifluoroacetic acid and dichloromethane volume ratio in the mixed solvent of 4: 1, the mass fraction of the solution is 13%, at room temperature into a stable, uniform solution, stand After a few minutes, inject the resulting solution into the electrospinning device to obtain a PET electrospun fiber membrane; then place the membrane between No. 1 industrial filter cloth and glass fiber and heat press at 180°C to form a sandwich composite nanofiltration material .

Embodiment 2

[0026] A certain mass of polyacrylonitrile (PAN) is dissolved in N, N-dimethylformamide (DMF), the mass fraction of the solution is 10%, and it becomes a stable and uniform solution at room temperature. After standing for a few minutes, The resulting solution was injected into an electrospinning device to prepare a PAN electrospun fiber membrane; then the membrane was placed between No. 1 industrial filter cloth and glass fiber and hot-pressed at 180°C to form a sandwich composite nanofiltration material.

Embodiment 3

[0028] A certain mass of nylon (PA6) particles was dissolved in a mixed solvent with a volume ratio of formic acid and glacial acetic acid of 8:2, the mass fraction of the solution was 12%, and it became a stable and uniform solution at room temperature. After standing for a few minutes, The resulting solution was injected into an electrospinning device to prepare a PA6 electrospun fiber membrane; then the membrane was placed between No. 1 industrial filter cloth and glass fiber and hot-pressed at 180°C to form a sandwich composite nanofiltration material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com