High-strength composite nano fiber long yarn and manufacturing method thereof

A technology of composite nanofibers and nanofibers, applied in fiber processing, filament/thread forming, fabrics, etc., can solve the problems of ineffective deposition of guiding filaments, high strength, etc., and achieve excellent mechanical properties, high efficiency, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

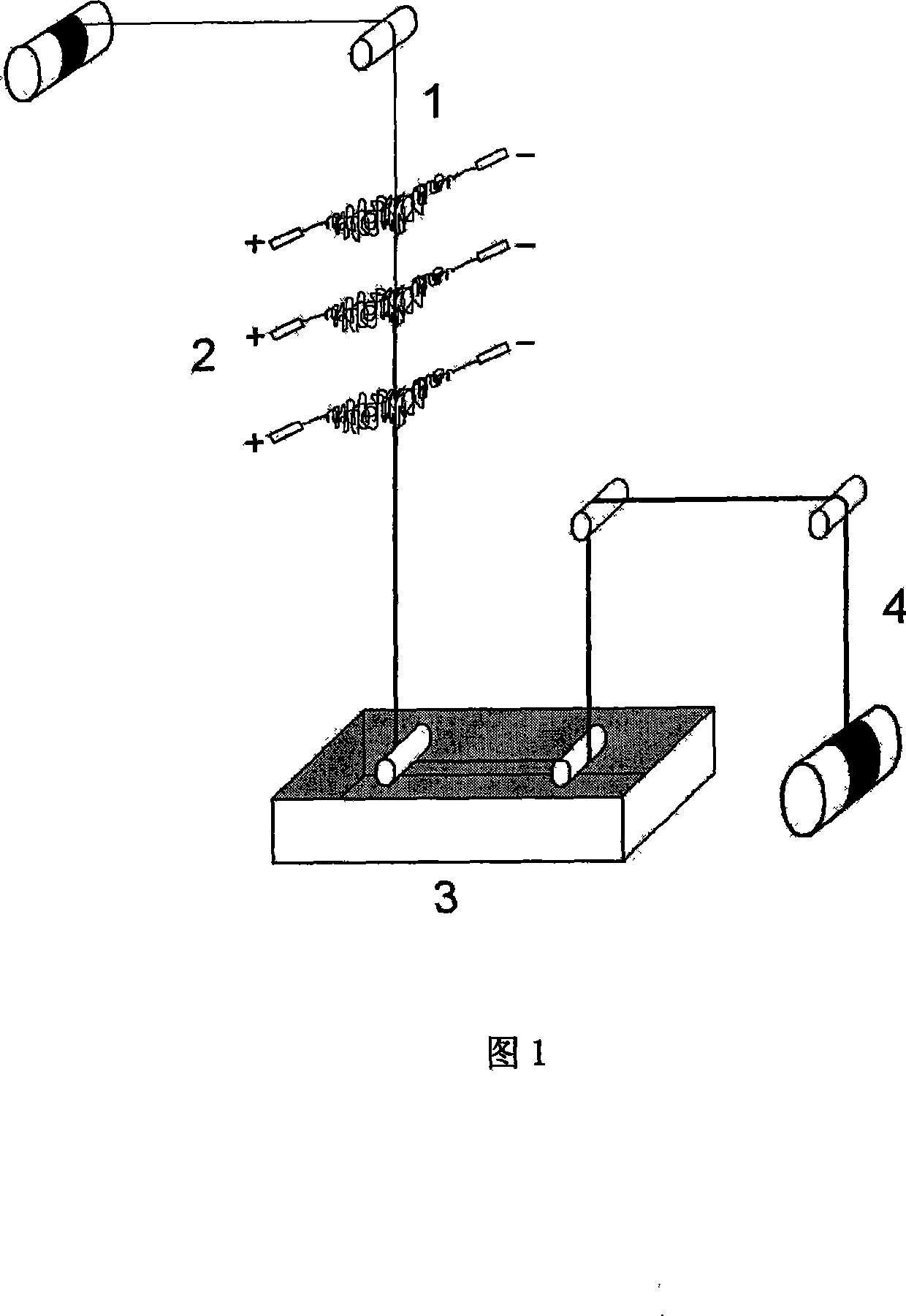

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 1.0g of collagen in 5ml of hexafluoroisopropanol, use chitosan yarn as the core material, and deliver the solution to a pair of spinnerets that are placed opposite to each other at a distance of 20cm from the core material. The inner diameter of the spinnerets is 0.6mm. The distance between the pairs is 25cm, and the opposite polarity DC high voltage ±8kv is applied to the spinneret respectively, and the collagen solution at the top of the spinneret is stretched and whipped under the action of the electric field force to form charged collagen nanoparticles. Fibers, the collagen nanofibers ejected from the spinneret opposite to the nozzle have opposite charges, attract and collide with each other in the air, and deposit on the central core material chitosan yarn pulled forward at a speed of 5m / min, to obtain The long chitosan yarn coated with collagen nanofibers has a tensile strength of 0.56cN / dtex and an elongation at break of 37%.

Embodiment 2

[0022]Dissolve 1.5g of gelatin in 20ml of trifluoroethanol, then add 0.05g of ibuprofen, ultrasonically oscillate, take silk as the core material, and deliver the solution to three pairs of spinnerets that are placed opposite each other at a distance of 50cm from the core material, with an inner diameter of 0.6mm , the distance between the spinneret pairs is 25cm, and the opposite polarity DC high voltage ±10kv is applied to the spinnerets respectively, and the gelatin solution at the top of the spinnerets is stretched and whipped under the action of the electric field force to form a charged Gelatin-ibuprofen nanofibers, the gelatin-ibuprofen nanofibers ejected from the spinneret opposite to the nozzle have opposite charges, attract and collide with each other in the air, and deposit on the silk core that is pulled forward at a speed of 10m / min On the material, obtain the long silk yarn of surface coating gelatin (containing ibuprofen) nanofiber. After further treatment in a ...

Embodiment 3

[0024] Dissolve 1.0 g of dextran in 10 ml of trifluoroacetic acid, use poly-L-lactic acid fiber long yarn as the core material, and deliver the solution to a pair of spinnerets that are placed opposite to each other at a distance of 20 cm from the core material, and the distance between the spinneret pairs is 20 cm , with an inner diameter of 0.4mm, apply DC high voltage +10kv of opposite polarity to the spinneret respectively, and the dextran solution at the top of the spinneret will be stretched and whipped under the action of the electric field force to form charged dextran Nanofibers, the dextran nanofibers ejected from the spinneret opposite to the nozzle have opposite charges, attract and collide with each other in the air, and deposit on the poly-L-lactic acid fiber filaments that are pulled forward at a speed of 2m / min , to obtain the poly-L-lactic acid fiber long yarn coated with dextran nanofibers. After further treatment in a methanol coagulation bath, a long yarn w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com