Device for directly combining nano fiber diaphragm on lithium ionic cell electrode surface and the method

A composite nanofiber, lithium-ion battery technology, applied in secondary batteries, active material electrodes, battery pack components, etc., can solve the problems of slow production speed, unsuitable for large-scale production, and inability to accurately control membrane performance, etc. The effect of meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

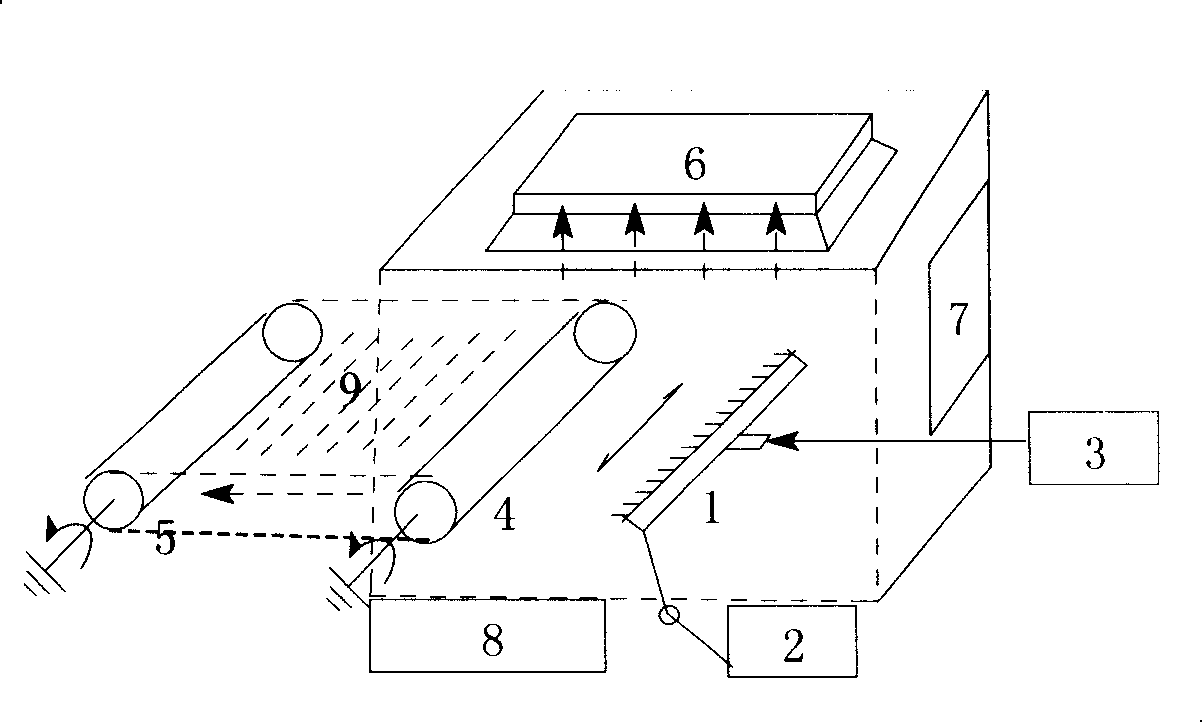

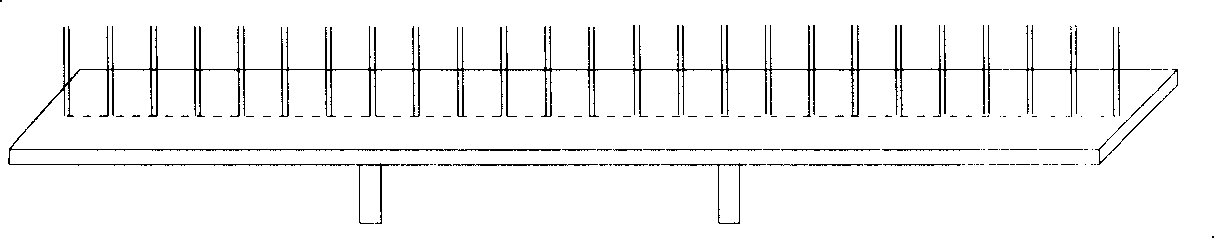

[0040] See Figure 1 ~ Figure 2 . A device with a temperature control device 7 and a mechanical control integration 8 for direct preparation of the electrode sheet surface of a lithium ion battery and a composite nanofiber diaphragm, the single-row multi-needle spinneret 1 of the electrospinning machine in the device (such as figure 2 shown) is connected to the negative high voltage output by one end of the high-voltage DC power supply 2 through a wire, and the feed hole of the multi-needle spinneret 1 is connected with the metering infusion pump 3 through a pipeline; There is a receiving roller 4 with a rotating motor, a solvent recovery device 6 is placed above the receiving roller 4, and a transmission winding device 5 with a rotating motor is installed in front of the receiving roller 4. The receiving roller 4 is connected to a high-voltage DC power supply 2 through a wire The other end is connected to the ground wire, and the receiving roller is effectively grounded thro...

Embodiment 2

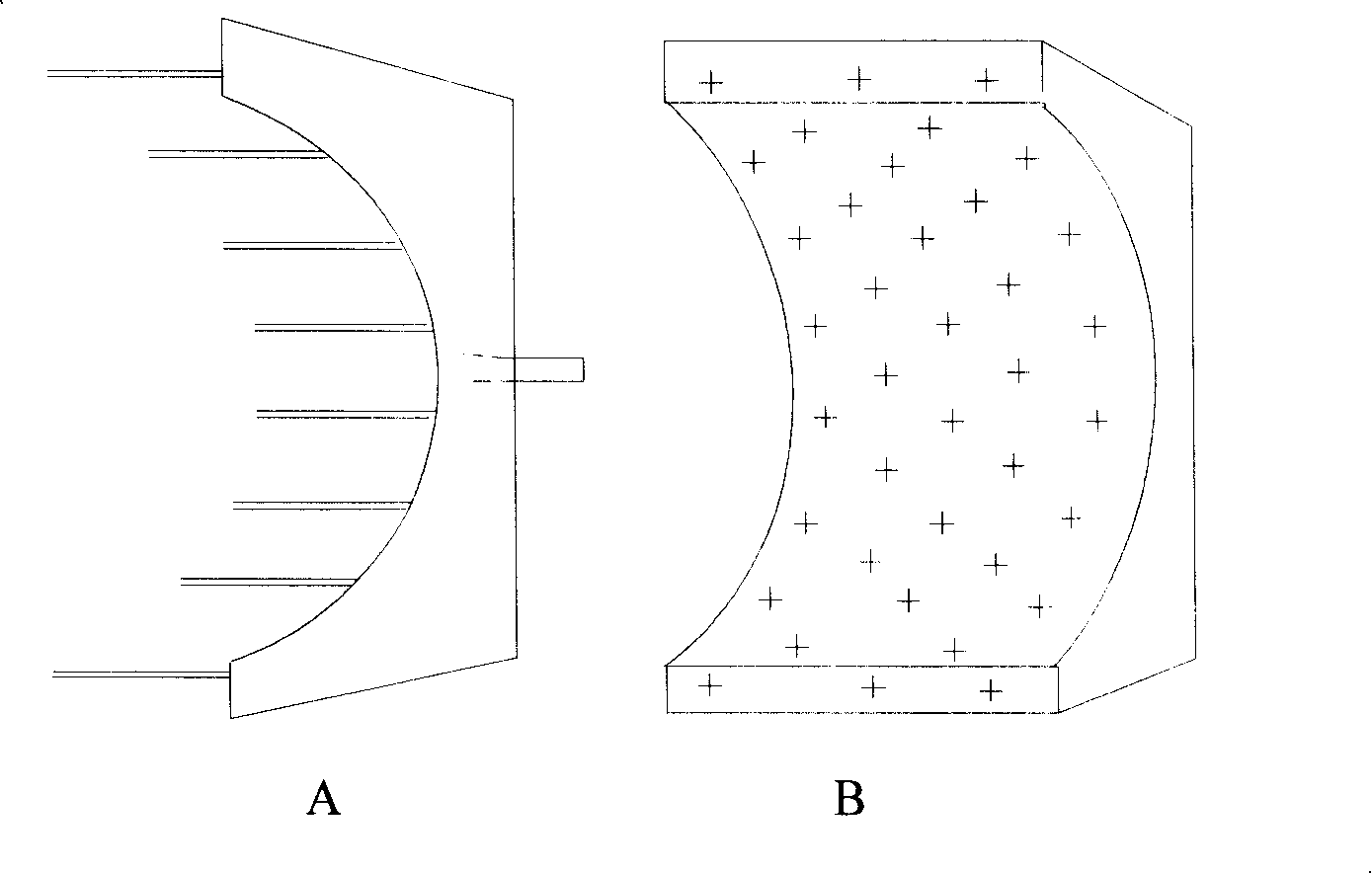

[0046] See figure 1 , image 3 . Device structure is the same as the device of embodiment 1, just change single-row multi-needle spinneret into dense array multi-needle spinneret (such as image 3 shown).

[0047] Prepare a polyacrylonitrile solution with a weight concentration of 9.5%. The viscosity of the solution is between 600 and 700mPa·S. Stir at 25°C for 7 days. The electrode sheet coated with the negative electrode material modified natural graphite on the surface of the metal copper foil is circulated between the receiving roller and the transmission winding device, the electrode sheet conveying speed is 120cm / min, the electric field applied between the spinneret and the electrode (receiving roller) The intensity is 1000V / cm, the distance is 20cm, and the moving speed of the spinneret is 30-60cm / min. Turn on the drive winding device, the receiving roller, the metering infusion pump and the motor of the electrospinning machine, and the polyacrylonitrile spraying l...

Embodiment 3

[0049] The device is the same as in Example 1.

[0050] Prepare a mixed solution containing polyvinylidene fluoride with a weight concentration of 7.5% and polyacrylonitrile with a weight concentration of 1.0%, add 1.0% polymethyl acrylate (both by weight percentage), and the viscosity of the solution is 600-700mPa·S In between, stir at 25°C for 7 days, filter and put it on the machine, and use a single row of multi-needle nozzles to scan and spray horizontally. The electrode sheet coated with the negative electrode material natural graphite on the surface of the metal copper foil is circulated and conveyed between the receiving roller and the transmission winding device, and the electrode sheet conveying speed is 120cm / min. The electric field strength applied between the spinneret and the electrode (receiving roller) is 1000V / cm, the distance is 18cm, and the moving speed of the spinneret is 30-60cm / min. Turn on the drive winding device, the receiving roller, the metering in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com