Photocurable resin composition for laminating optically functional material

A resin composition and light-curing technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, graft polymer adhesives, etc., can solve the problem of peeling of the adhesive surface, LCD display spots, LCD problems such as rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

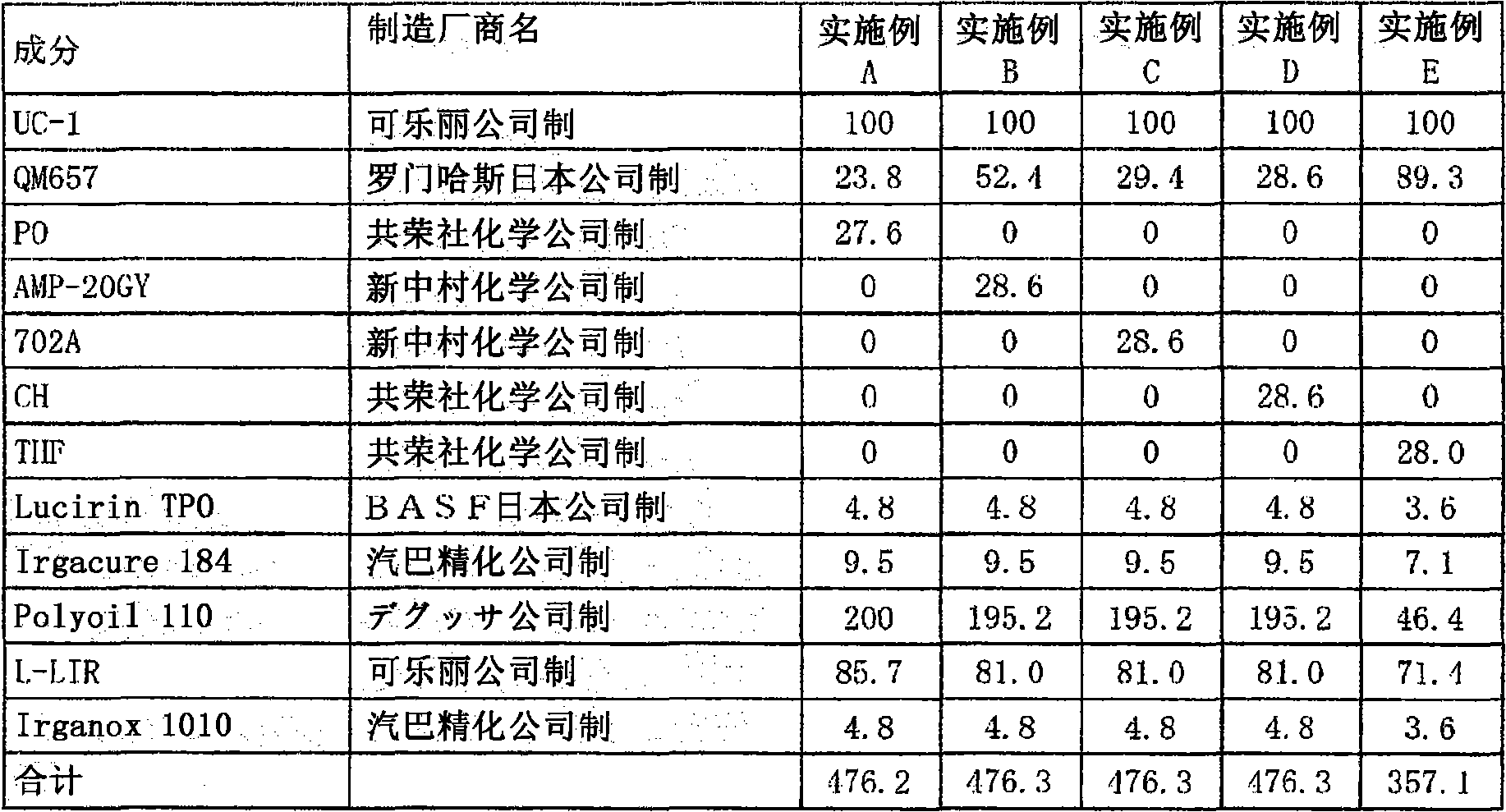

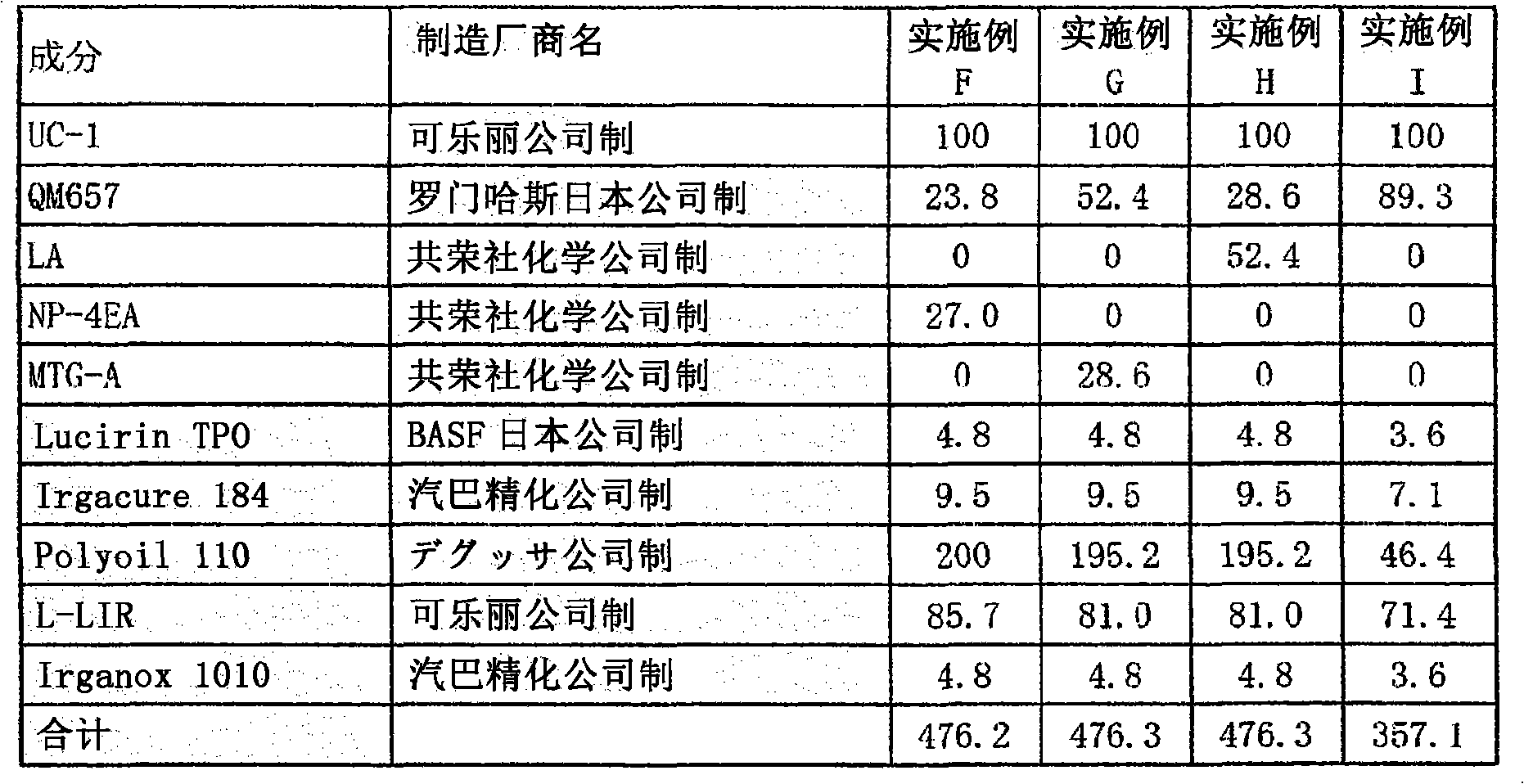

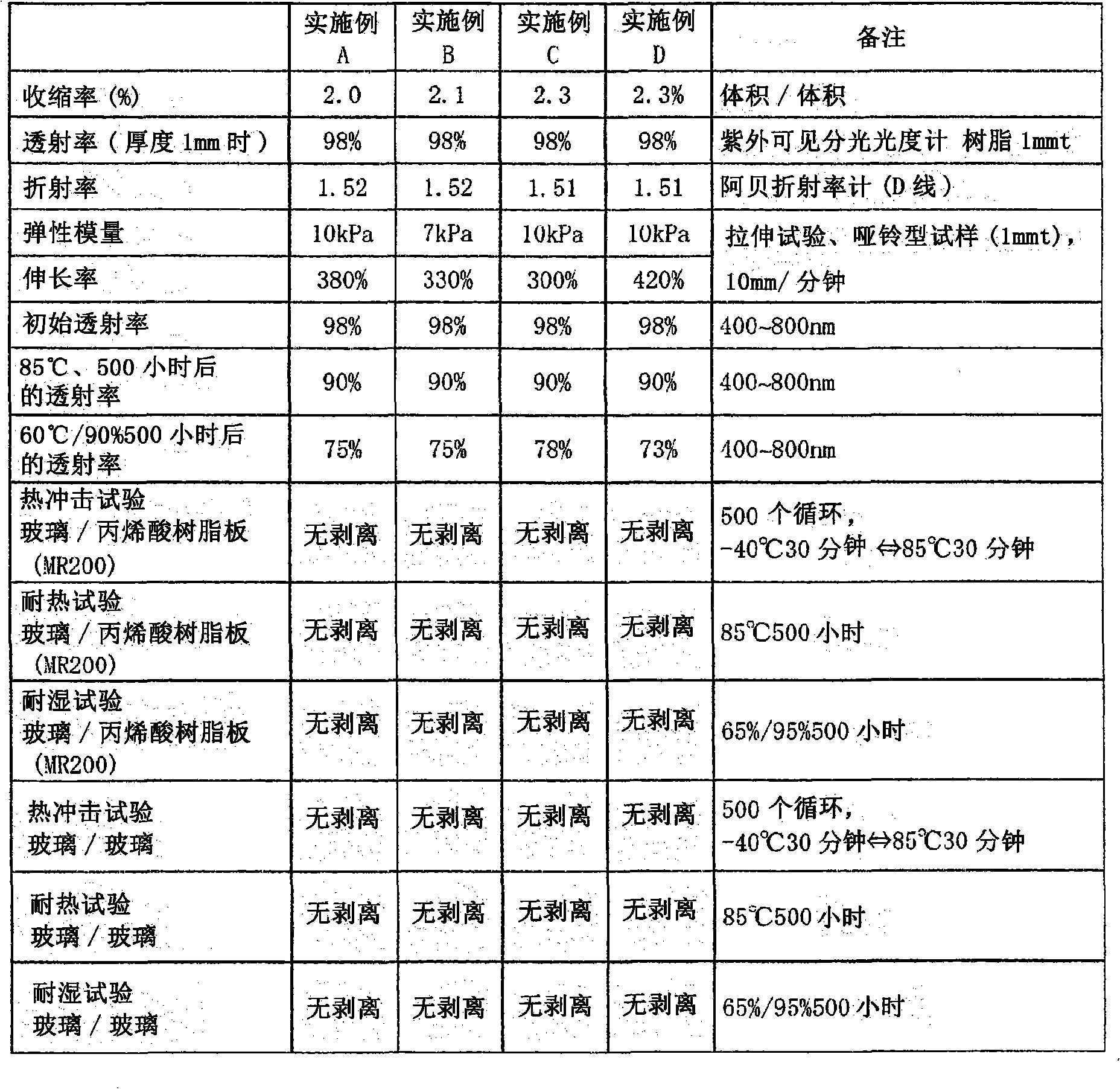

[0081] The components shown in Tables 1 and 2 were mixed in the amounts (parts by mass) shown in Tables 1 and 2 to obtain the photocurable resin compositions of Examples A to I.

[0082] Table 1

[0083]

[0084] Table 2

[0085]

[0086] UC-1: polyisoprene methacrylate oligomer (molecular weight 25000)

[0087] QM657: Dihydrodicyclopentadienyloxyethyl methacrylate

[0088] LA: lauryl acrylate

[0089] CH: cyclohexyl methacrylate

[0090] PO: Phenoxyethyl methacrylate

[0091] AMP-20GY: Phenoxypolyethylene glycol acrylate

[0092] 702A: 2-Hydroxy-3-phenoxypropyl acrylate

[0093] THF: tetrahydrofurfuryl methacrylate

[0094] NP-4EA: Nonylphenol EO Adduct Acrylate

[0095] MTG-A: Methoxytriethylene glycol acrylate

[0096] Lucirin TPO: 2,4,6-Trimethylbenzoylphenylethoxyphosphine oxide

[0097] Irgacure 184: 1-Hydroxycyclohexyl phenyl ketone

[0098] Polyoil 110: liquid polybutadiene

[0099] L-LIR: Liquid Polyisoprene

[0100] Irganox 1010: Pentaerythritol tetr...

Embodiment 2

[0118] The components shown in Table 6 were mixed in the quantities shown in Table 6 to obtain photocurable resin compositions of Examples A2 to H2.

[0119]

[0120] UC-1: polyisoprene methacrylate oligomer (molecular weight 25000)

[0121] HOB: 2-Hydroxybutyl methacrylate

[0122] QM657: Dihydrodicyclopentadienyloxyethyl methacrylate

[0123] BZ: benzyl methacrylate

[0124] Karenz PE-1: Pentaerythritol tetrakis (3-mercaptobutyrate)

[0125] TMMP: Trimethylolpropane tris(3-mercaptopropionate)

[0126] LucirinTPO: 2,4,6-Trimethylbenzoylphenylethoxyphosphine oxide

[0127] Irgacure 184: 1-Hydroxycyclohexyl phenyl ketone

[0128] Polyoil 110: liquid polybutadiene

[0129] L-LIR: Liquid Polyisoprene

[0130] Irganox 1010: Pentaerythritol tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]

[0131] Irganox 1520L: 4,6-bis(octylthiomethyl) o-cresol

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com