Propenyl hot-melt adhesive composition and preparation method thereof

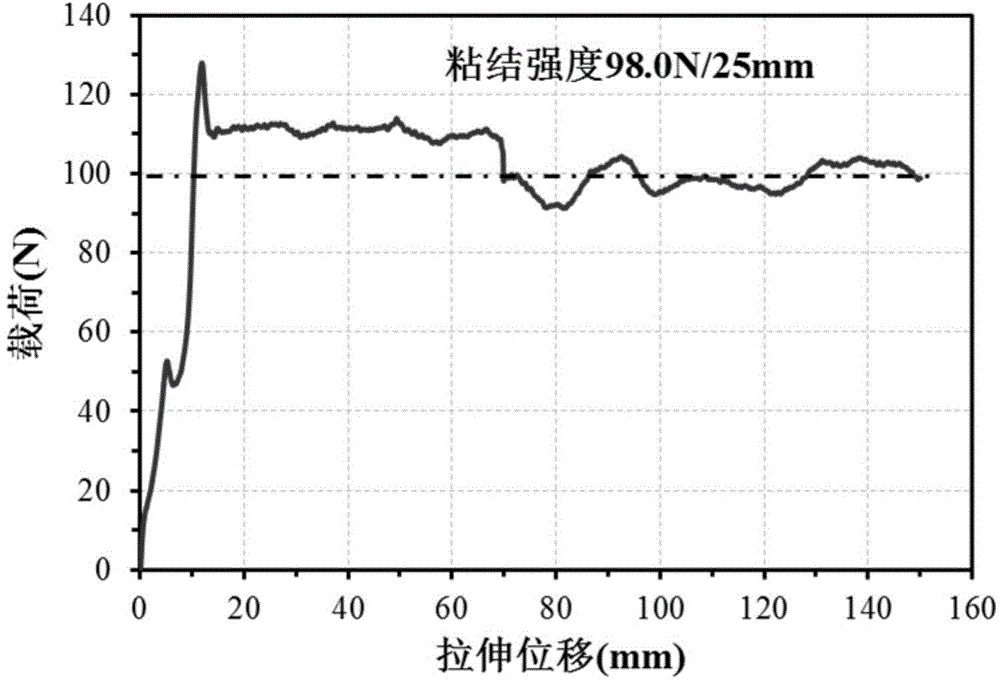

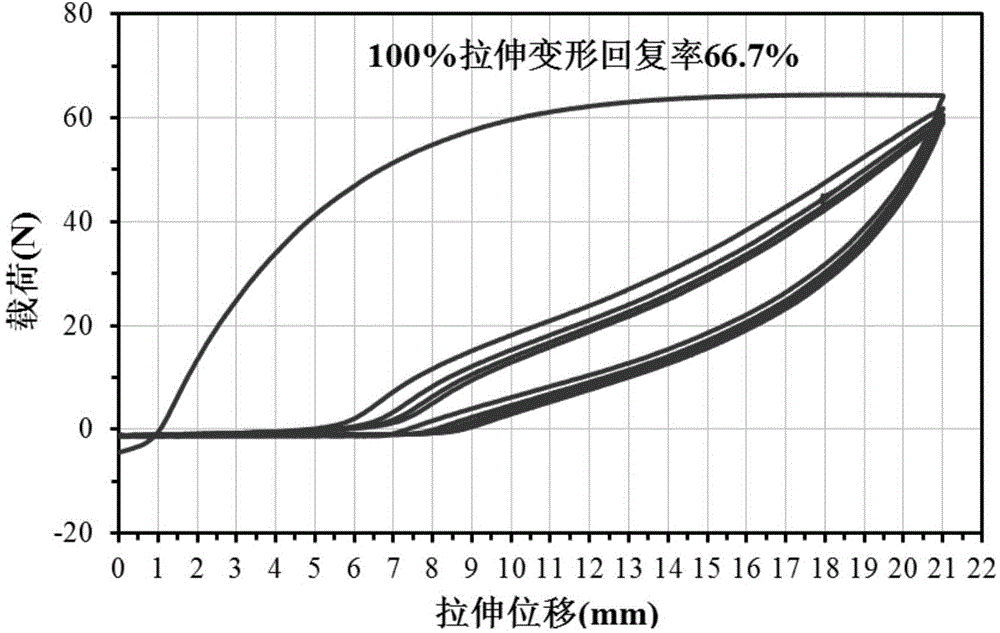

A technology of propylene-based heat and composition, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve problems such as hidden dangers in the use of steel-plastic composite pipes, increased processing difficulty and cost, and depressions. Achieve the effects of high controllable processing fluidity, high cohesion and deformation recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a propylene-based hot melt adhesive composition, which is characterized in that the propylene-based hot melt adhesive composition contains the following components:

[0030] (A) Polypropylene;

[0031] (B) Polyolefin elastomer;

[0032] (C) Polar monomer;

[0033] (D) Grafting initiator; and

[0034] Optionally, (E) other auxiliary agents.

[0035] Component (A) Polypropylene

[0036] Polypropylene is the matrix component of the propylene-based hot-melt adhesive composition of the present invention and imparts the adhesive properties of the adhesive.

[0037] Polypropylene (PP) includes propylene homopolymer, propylene and other C 2-20 Random copolymers or block copolymers formed by α-olefins, as well as propylene and ethylene and a kind of other C 2-20 α-olefin terpolymer.

[0038] The above C 2-20 Examples of α-hydrocarbons include ethylene, 1-butene, 2-butene, 1-pentene, 1-hexene, 1-heptene, 1-octene, 1-decene, 1-dodecene, 4-methyl-1-pentene, 2-meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com