In-pipe Rubber bladder hydraulic forming device

A technology of hydroforming and rubber bladder, applied in the field of metal pressure processing, can solve the problems of waste of pipes, high requirements for end sealing of pipe fittings, long forming cycle, etc. The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

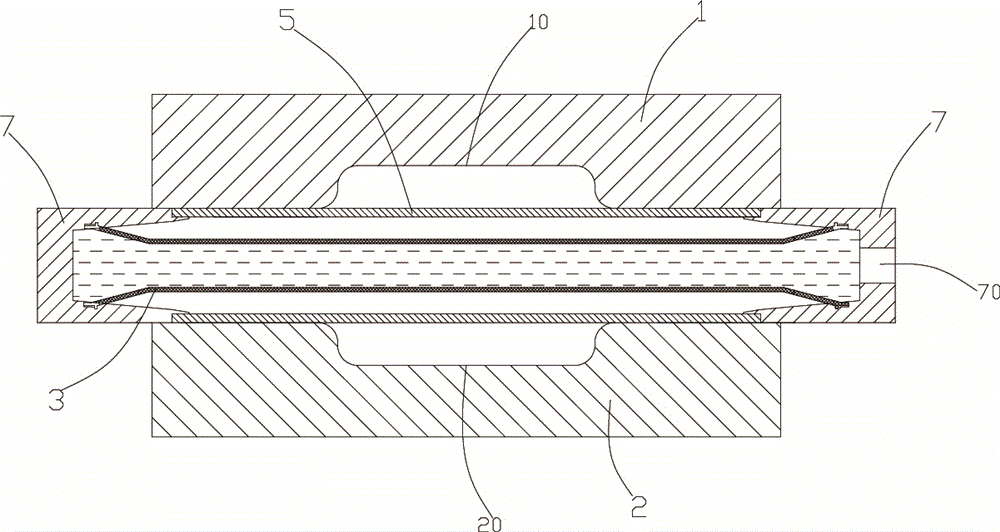

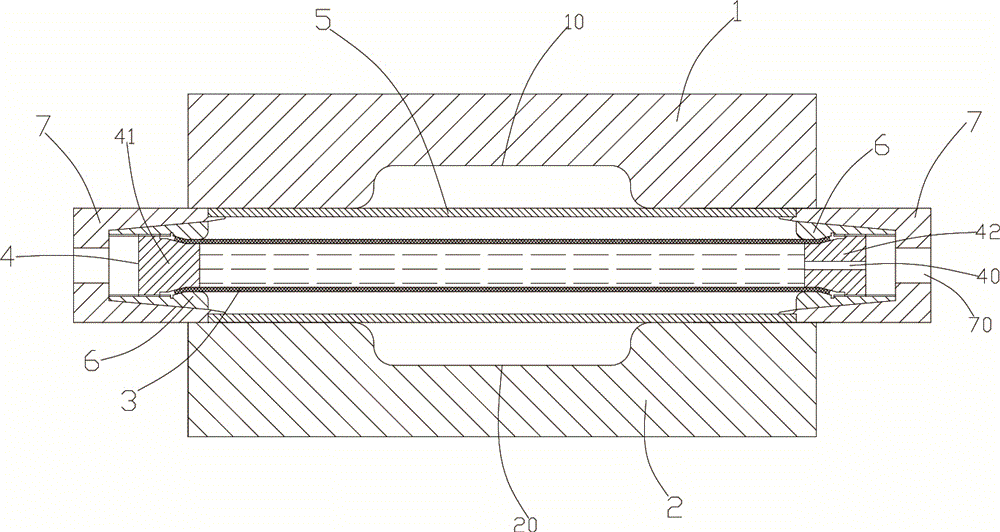

[0035] see figure 1 and figure 2 As shown, a specific embodiment of the rubber bag hydroforming device in the pipe of the present invention. A hydroforming device for a rubber bladder in a tube, comprising an upper mold 1 and a lower mold 2, the upper mold 1 is provided with an upper mold cavity 10, and the lower mold is provided with a lower mold cavity 20, after closing the upper mold cavity 10 and the lower mold cavity The cavities 20 are combined into a complete molding cavity. The shape of the cavity is determined by the shapes of different processed pipe fittings. A push rod 7 is arranged symmetrically between the upper die 1 and the lower die 2. On the push rod 7 A structure for medium injection is provided, which is an injection hole 70 for injecting the medium. The injection hole 70 is arranged on the push rod 7 on one side, and a rubber bag 3 is arranged between the push rods 7, and the rubber bag 3 The outer side is the pipe fitting 5 to be formed, and the two en...

Embodiment 2

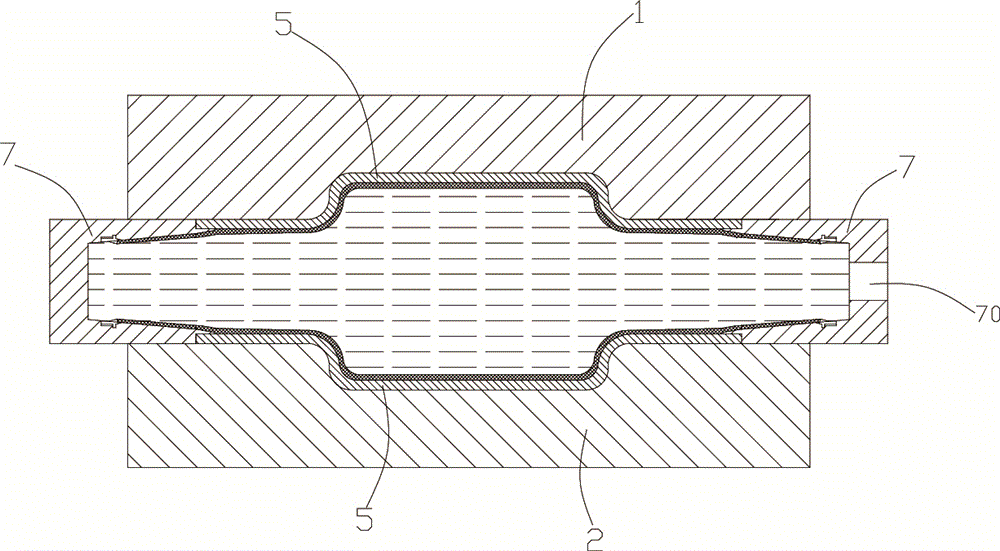

[0042] see image 3 and Figure 4 Shown, another specific embodiment of the hydroforming device of the rubber bag in the tube of the present invention. A hydroforming device for a rubber bladder in a tube, comprising an upper mold 1 and a lower mold 2, the upper mold 1 is provided with an upper mold cavity 10, and the lower mold is provided with a lower mold cavity 20, after closing the upper mold cavity 10 and the lower mold cavity The cavities 20 are combined into a complete molding cavity. The shape of the cavity is determined by the shapes of different processed pipe fittings. A push rod 7 is arranged symmetrically between the upper die 1 and the lower die 2. On the push rod 7 A structure for medium injection is provided, and the structure is an injection hole 70 for injecting medium. The injection hole 70 is arranged on one of the push rods 7 on one side, and a rubber bag 3 is arranged between the push rods 7 .

[0043] In the above technical solution, the two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com