Battery isolating film and method for producing the same

A battery separator and separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of polyolefin material melting, battery fire, separator damage, etc., and achieves low thermal shrinkage, good permeability, and high mechanical properties. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

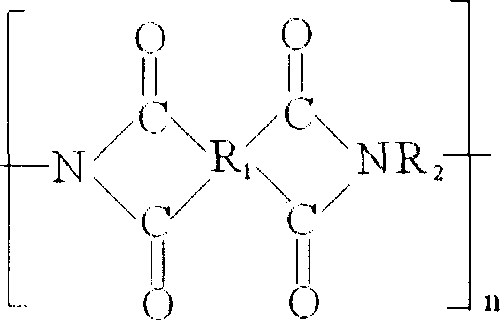

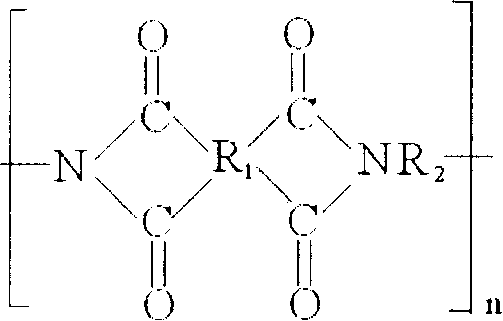

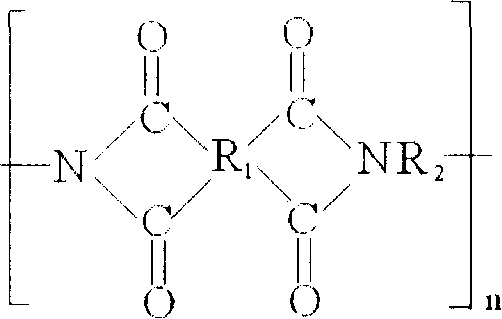

[0020] The preparation method of the battery separator provided by the invention comprises forming a film from a solution containing a base material, a solvent, and a pore-forming substance, removing the pore-forming substance to obtain a porous film, and then coating the polyolefin solution on the porous film and heating it under vacuum, Cooling and phase separation, wherein the base material contains polyimide, and the holes on the base material contain a polyolefin layer.

[0021] In the present invention, there is no special limitation on the amount of polyimide, pore-forming substance, solvent and polyolefin, which is determined according to the required pore density and pore size of the battery separator. Preferably, the weight ratio of the polyimide to the pore-forming substance is 100:20-60, more preferably 100:40-50, and the weight ratio of the polyimide to the solvent is 8-15:100 , more preferably 9-12:100, the weight ratio of polyimide to polyolefin is 100:5-50, mor...

Embodiment 1

[0038] This example is used to illustrate the battery separator provided by the present invention and its preparation method.

[0039] 2500 parts by weight of pyromellitic dianhydride (PMDA, Liyang Longsha Chemical Co., Ltd.) and 2450 parts by weight of diaminodiphenyl ether (ODA, Shanghai Test Machine No. 3 Factory) are synthesized into a polyamic acid solution; The polyamic acid of weight part and the magnesium hydroxide whisker (M-HOW of Yingkou Wesike Chemical Co., Ltd.) of 1900 weight parts in the N of 49500 weight parts, N-dimethylacetamide (DMAC, Shanghai Jingwei Chemical Co., Ltd. ) and mix well. Then apply a coating film on glass to obtain a sheet with a thickness of 0.4 mm. Treat the sheet at 90°C for 5 hours to remove the solvent, program the temperature to 320°C at a rate of 6°C / min, and heat for 3 hours. , carry out imidization to obtain an inorganic hybrid polyimide film, and the thickness of the porous film is 15 microns.

[0040] The hybrid film was immersed ...

Embodiment 2

[0043] This example is used to illustrate the battery separator provided by the present invention and its preparation method.

[0044] 2500 parts by weight of biphenyltetracarboxylic dianhydride (潥yang Longsha Chemical Co., Ltd.) and 2500 parts by weight of diaminobenzophenone (Shanghai Test Machine No. 3 Factory) are synthesized into a polyamic acid solution; Polyamic acid and 2000 parts by weight of basic magnesium sulfate whiskers (Yingkou Wesker Chemical Co., Ltd.) were uniformly mixed in 42000 parts by weight of N-2-dimethylpyrrolidone (Shanghai Jingwei Chemical Co., Ltd.). Then apply a coating film on glass to obtain a sheet with a thickness of 0.4 mm. Treat the sheet at 90°C for 5 hours to remove the solvent, program the temperature to 310°C at a rate of 7°C / min, and heat for 3 hours. , carry out imidization to obtain an inorganic hybrid polyimide film, and the thickness of the porous film is 15 microns.

[0045] The hybrid film was immersed in an aqueous sulfuric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com