Multifunctional cigarette cracking capsule based on liquid marble and preparation method of multifunctional cigarette cracking capsule

A liquid marble and multi-functional technology, applied in tobacco, e-liquid filter elements, applications, etc., can solve the problems of inability to realize large-scale batch production, complicated preparation process of functional filters, poor stability, etc., and achieve function adjustable Strong, excellent stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] On the plastic substrate scattered with hydrophobic powder, drop 10 μL of saturated potassium acetate droplet with a microsampler, and then shake the substrate to make the surface of the droplet fully cover the powder to form a liquid marble.

[0023] Make a mixture of epoxy soybean oil acrylic resin and diluent at a volume ratio of 1:5, then add 3% of the I-184 photoinitiator by mass fraction, stir and mix evenly, and spray it on the surface of the liquid marbles in a UV light curing machine and solidified for 3 minutes to obtain microcapsules.

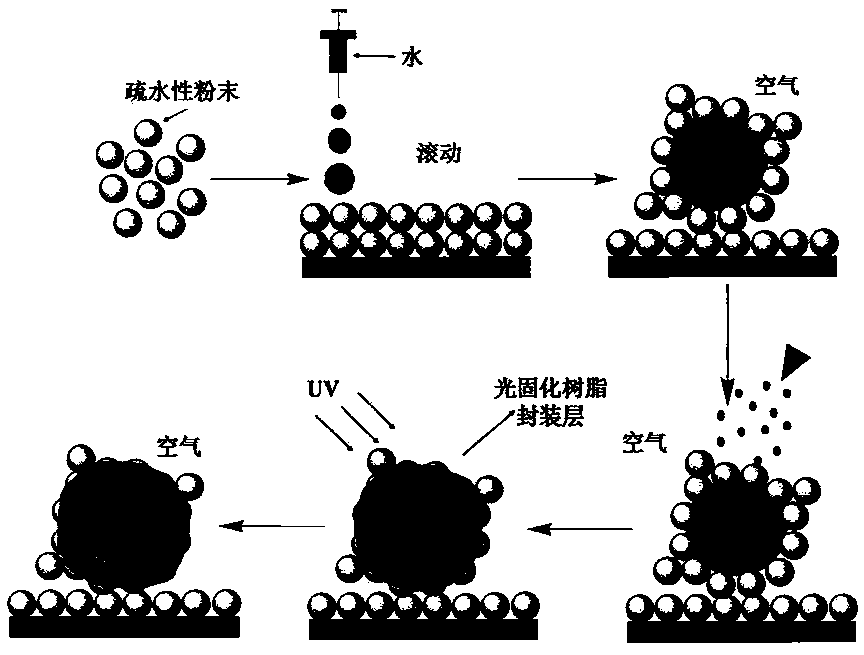

[0024] Implementation effect of this embodiment: figure 1 It is a schematic diagram of the preparation route of microcapsules. The hydrophobic powder is used as a stabilizer to prepare liquid marbles by a rolling drop method, and a photocurable coating containing an initiator is sprayed on the outside of the liquid marbles, and cured by ultraviolet radiation to obtain capsules.

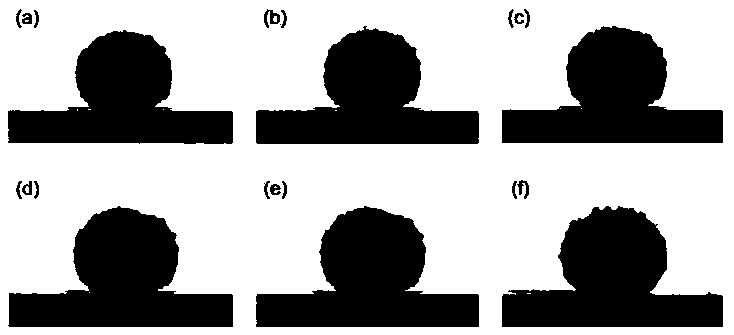

[0025] figure 2 Digital photographs for the...

Embodiment 2

[0029] On the plastic substrate scattered with hydrophobic powder, drop 10 μL of saturated potassium acetate droplet with a microsampler, and then shake the substrate to make the surface of the droplet fully cover the powder to form a liquid marble.

[0030] Make a mixture of epoxy soybean oil acrylic resin and diluent at a volume ratio of 1:3, then add 4% of the I-184 photoinitiator by mass fraction, stir and mix evenly, and spray it on the surface of the liquid marbles in a UV light curing machine Curing at lower temperature for 4 minutes to obtain microcapsules.

Embodiment 3

[0032] On the plastic substrate scattered with hydrophobic powder, drop 10 μL of saturated potassium acetate droplet with a microsampler, and then shake the substrate to make the surface of the droplet fully cover the powder to form a liquid marble.

[0033] Make a mixture of epoxy soybean oil acrylic resin and diluent at a volume ratio of 1:1, then add 4% of the I-184 photoinitiator by mass fraction, stir and mix evenly, and spray it on the surface of the liquid marbles in a UV light curing machine Curing at lower temperature for 2 minutes to obtain microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com