Preparation method and application of organosilicone flame-retardant fireproof coating

A technology for fire-retardant coatings and silicones, applied in fire-resistant coatings, coatings, etc., can solve the problems of easy aging, easy combustion, poor fire safety, etc., and achieve the effect of simple preparation method and good bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 20g of MQ resin, add 20g of hydrogen-containing silicone oil, stir well and evenly under mechanical stirring, and use it as component A; add 48g of vinyl silicone resin, add 20g of platinum complex containing 40ppm, stir fully and evenly under mechanical stirring, and use it as component B; After mixing Group A and B with equal mass for 5 minutes, a silicone flame retardant coating was obtained. Dip or spray it on flammable materials such as epoxy resin, and leave it at room temperature to cure for 120 minutes to obtain a silicone flame retardant coating modified epoxy resin sample. The combustion comparison results show that the uncoated epoxy resin sample burns rapidly, accompanied by the burning material dripping in the molten droplet state and a large amount of harmful smoke. In comparison, the epoxy resin splines modified with silicone flame retardant coatings still maintain the basic shape of the foam within 30s, and after burning for 10s, they can be self-ext...

Embodiment 2

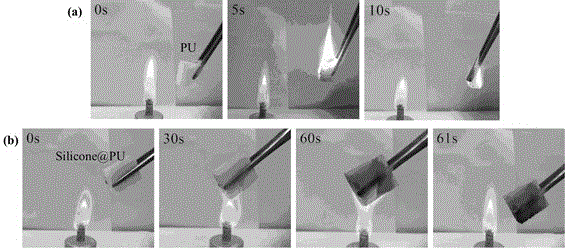

[0024] Add 20g of vinyl silicone resin, 15g of hydrogen-containing silicone oil, 7g of phenyl silicone oil and 3g of nano-silica filler, stir well and evenly under mechanical stirring, and use it as component A; add 40g of vinyl silicone resin, add 100ppm platinum complex Mix 50g of the material, fully and evenly with mechanical stirring, as component B; after mixing components AB and equal mass for 5 minutes, a silicone flame retardant coating is obtained. Spray or apply it to flammable materials such as polyurethane foam, and leave it at room temperature for 90 minutes to cure, and then the surface-modified polyurethane foam material of the silicone flame-retardant coating is prepared.

[0025] The combustion comparison test results are as follows: figure 1 As shown, the polyurethane (PU) foam is easy to ignite, and a large amount of harmful smoke will be generated during the combustion process, and the combustion will be basically completed within 10s. Under the same size ...

Embodiment 3

[0027] Add 15g of hydrogen-containing silicone resin, 15g of silane KH550, 5g of silicone rubber and 15g of layered silicate, stir well and evenly under mechanical stirring, and use it as component A; add 45g of vinyl silicone resin, add 50ppm of platinum complex 50g, fully homogenized by mechanical stirring, as component B; after mixing components AB and equal mass for 5 minutes, a silicone flame retardant coating was obtained. Spray it on the surface of flammable materials such as EPS, and leave it at room temperature for 15 minutes to cure, and then the prepared silicone flame retardant coating surface modifies the EPS material. The results of the combustion comparison test show that: EPS materials are easy to ignite and produce a large amount of toxic gases; however, EPS materials modified with silicone flame-retardant coatings cannot be ignited. According to UL test standards, they have reached the V0 flame-retardant standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com