Method for preparing gold nanoparticles

A gold nanoparticle, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Uniformity, nano- or micro-morphological differences, etc., to achieve good surface plasmon resonance properties, no toxic side effects, easy preparation and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

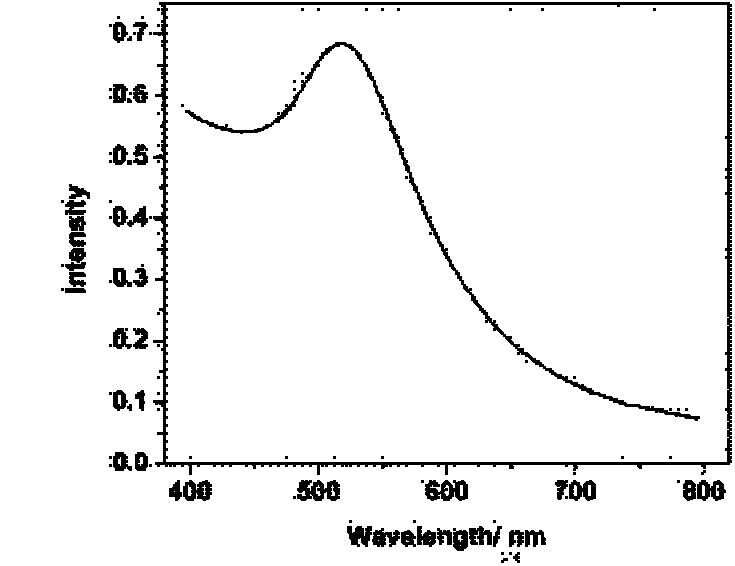

[0020] First, chloroauric acid (HAuCl 4 ·3H 2O) be made into 0.1M / L aqueous solution, take 20mL and 5M / L 2,6-pyridinedicarboxylic acid aqueous solution 20mL mix and stir under the water bath heating condition of 80 ℃, after reaction lasts 15 minutes, the color of solution From the original nearly colorless to pink, the color gradually deepens as time goes by, and finally turns red. After the reaction is stopped, the solution is slowly cooled to room temperature, and the resulting solution is centrifuged at 8000 rpm. Centrifuge at the speed of 10 minutes, discard the supernatant, remove the unreacted reducing agent 2,6-pyridinedicarboxylic acid, and re-disperse the obtained precipitate into ultrapure water with the same volume as the original, and then obtain 2 , 6-pyridinedicarboxylic acid protected gold nanoparticles. The obtained gold nanoparticles were tested for their absorption by ultraviolet-visible spectroscopy (UV-vis) to verify their surface plasmon resonance proper...

Embodiment 2

[0022] First, chloroauric acid (HAuCl 4 ·3H 2 O) be made into 0.1M / L aqueous solution, get 30mL and 5M / L 2,6-pyridinedicarboxylic acid aqueous solution 5mL mix and stir under the water bath heating condition of 50 ℃, after reaction continues 30 minutes, the color of solution From the original nearly colorless to pink, the color gradually deepens as time goes by, and finally turns red. After the reaction is stopped, the solution is slowly cooled to room temperature, and the resulting solution is centrifuged at 6000 rpm. Centrifuge at a speed of 15 minutes, discard the supernatant, and remove the unreacted reducing agent 2,6-pyridinedicarboxylic acid, and then ultrasonically disperse the resulting precipitate into ultrapure water of the same volume as the original to obtain 2 , 6-pyridinedicarboxylic acid protected gold nanoparticles. The obtained gold nanoparticles were tested for their absorption by ultraviolet-visible spectroscopy (UV-vis) to verify their surface plasmon re...

Embodiment 3

[0024] First, chloroauric acid (HAuCl 4 ·3H 2 O) be made into 0.1M / L aqueous solution, take 25mL and 5M / L 2,6-pyridinedicarboxylic acid aqueous solution 15mL mix and stir under the water bath heating condition of 70 ℃, after reaction continues 20 minutes, the color of solution From the original nearly colorless to pink, the color gradually deepens as time goes by, and finally turns red. After the reaction is stopped, the solution is slowly cooled to room temperature, and the resulting solution is centrifuged at 7000 rpm. Centrifuge at a speed of 15 minutes, discard the supernatant, and remove the unreacted reducing agent 2,6-pyridinedicarboxylic acid, and then ultrasonically disperse the resulting precipitate into ultrapure water of the same volume as the original to obtain 2 , 6-pyridinedicarboxylic acid protected gold nanoparticles. The obtained gold nanoparticles were tested for their absorption by ultraviolet-visible spectroscopy (UV-vis) to verify their surface plasmon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com