Air-breathing worktable for repairing solar cell laminates

A technology for solar cells and laminates, applied in lamination, electrical components, circuits, etc., can solve problems such as large effort, bending deformation of battery components, and rupture of battery sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

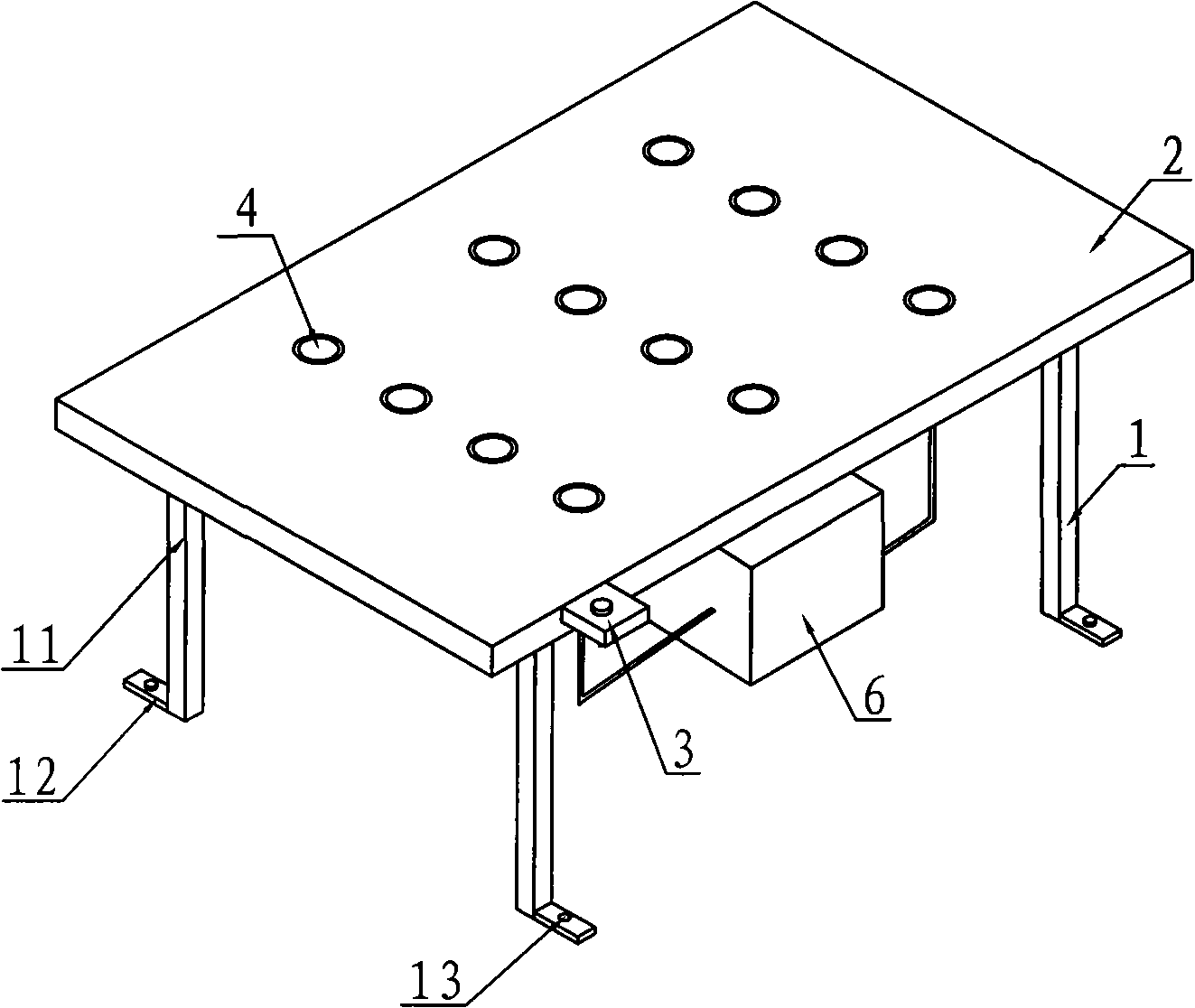

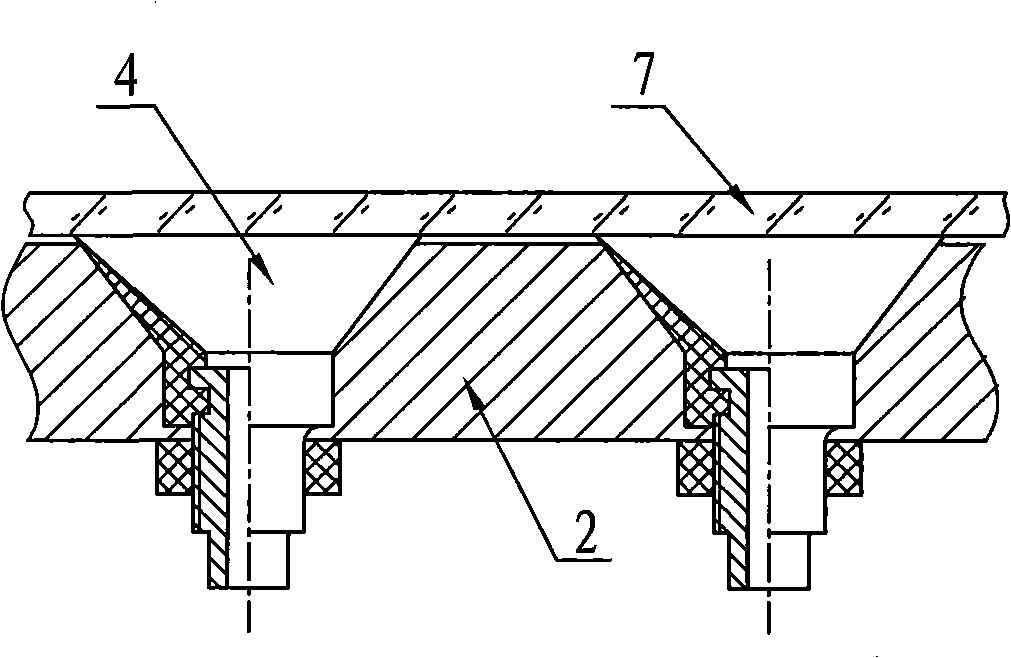

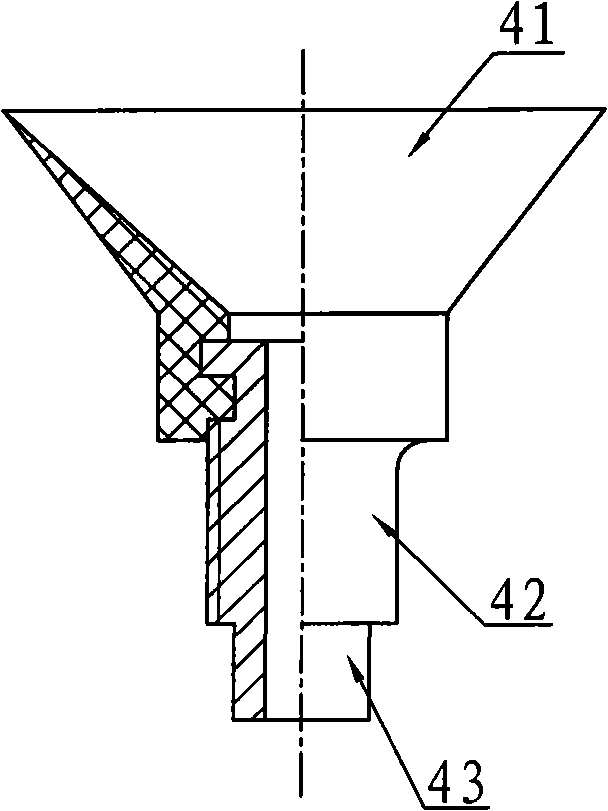

[0019] Example 1: The air-breathing solar cell laminate rework bench, such as Figure 1 to Figure 5 As shown, it includes a table frame 1, a desktop board 2, an electric controller 3, a suction cup 4, a vacuum generator 5 and a vacuum adsorption circuit 6, and a fixed plate 12 is provided at the bottom of the table leg 11 of the table frame 1, and the fixed plate 12 There are mounting holes 13, the upper end surface of the table frame 1 is in the same plane and parallel to the horizontal plane, the table top board 2 is fixed on the table frame 1, the suction cups 4 are evenly distributed on the table top board 2, and the top surfaces of all suction cups 4 are In the same plane, and 0.1mm~0.5mm higher than the upper end surface of the desktop board 2, the suction cup 4 is composed of a cone suction cup 41, a fixed thread section 42 and a casing section 43, and the cone suction cup 41 is arranged on the fixed thread. The upper end of the section 42, the casing section 43 is arra...

Embodiment 2

[0021] The desktop board 2 in Example 1 is set at an angle so that it forms an included angle of 10° to 30° with the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com