A/B shaft used for ultrasound scanning and examination of complex shape/contour

An ultrasonic and B-axis technology, which is applied in the direction of material analysis, measurement device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problems of difficult detection of irregular specimens and complicated triaxial devices, and achieves improved accuracy and efficiency. The effect of small footprint and strong interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described in detail below:

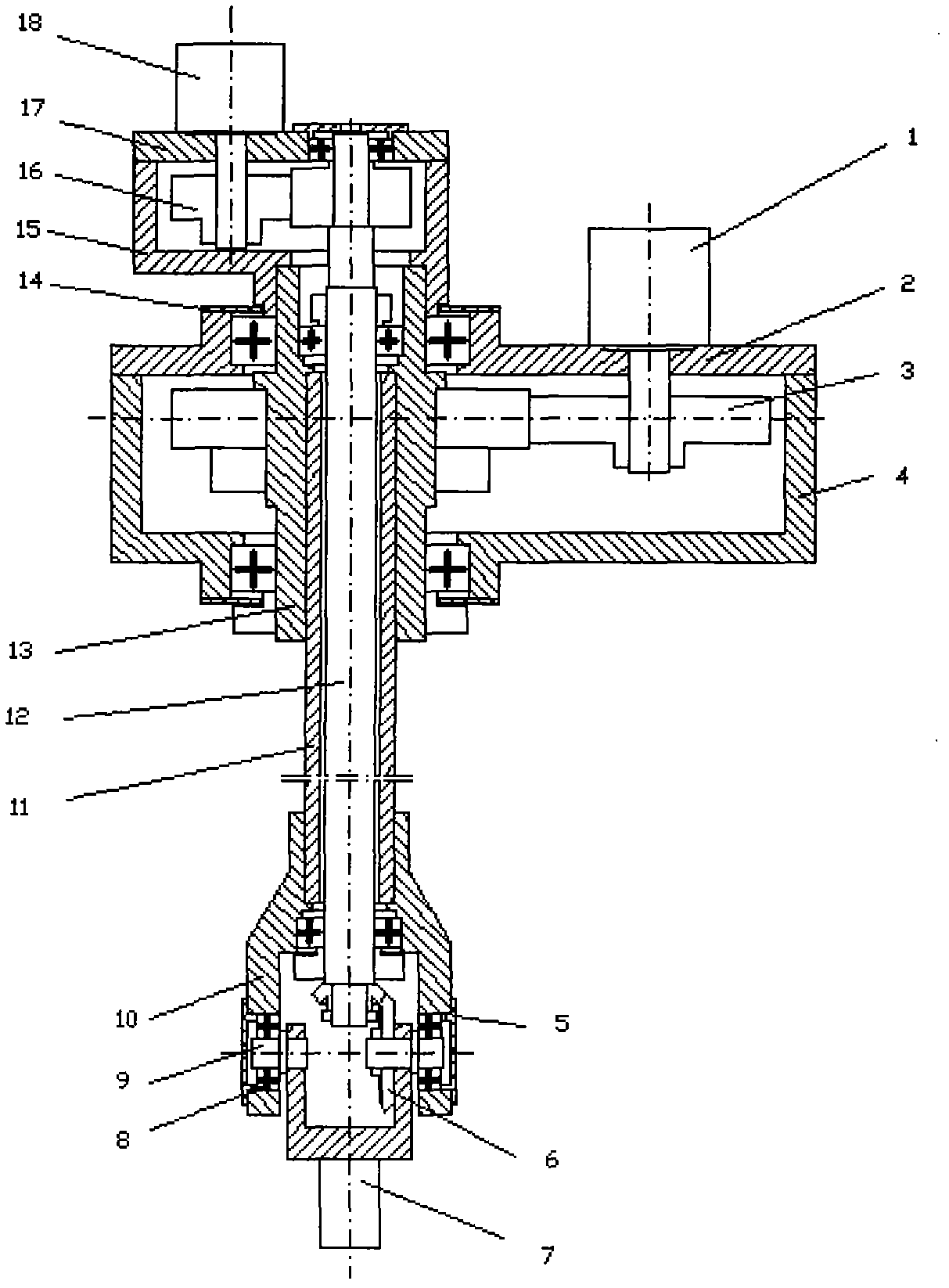

[0023] attached figure 1 The main structural components include stepping motor 1, 18, base cover 2, 17, spur gear pair 3, 16, base 4, 15, end cover 5, spur bevel gear 6, probe base 7, bearing 8. Drive shafts 9, 12, probe support frame 10, sleeve 11, sleeve shaft 13, bearing cover 14.

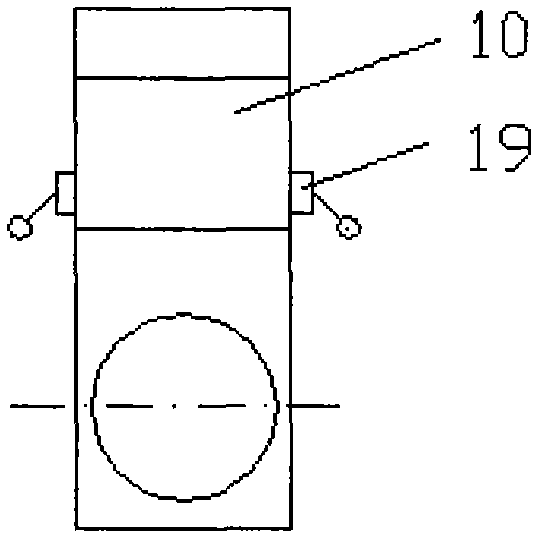

[0024] attached figure 2 Another view of the probe support frame 10 includes a travel limit switch 19 .

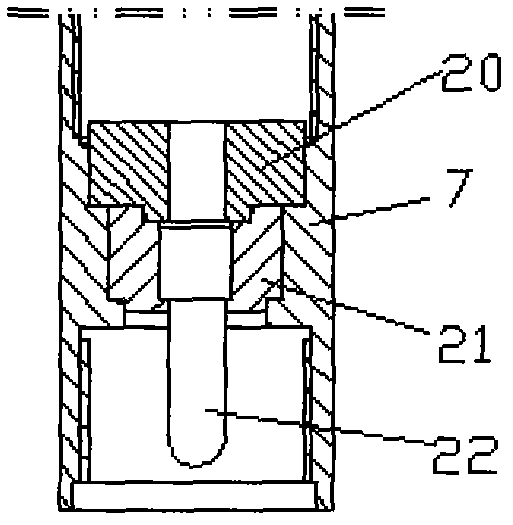

[0025] attached image 3 It is a sensor probe seat structure, including a nylon top block 20, a probe seat 7, a nylon block 21 for fixing UHF male pins, and a UHF male pin 22.

[0026] The device controls the A and B axes respectively through two stepping motors, wherein the motor 18 is used to control the rotation of the transmission shaft 12, and then transmits the motion to the probe base 7 through a pair of bevel gears 6 to realize the rotation of the probe . The whole B-axis device is driven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com