Ventilation encapsulation method for fuel cell pile

A technology of fuel cell stacks and packaging methods, which is applied in the direction of fuel cells, fuel cell additives, fuel cell groups, etc., and can solve problems such as easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

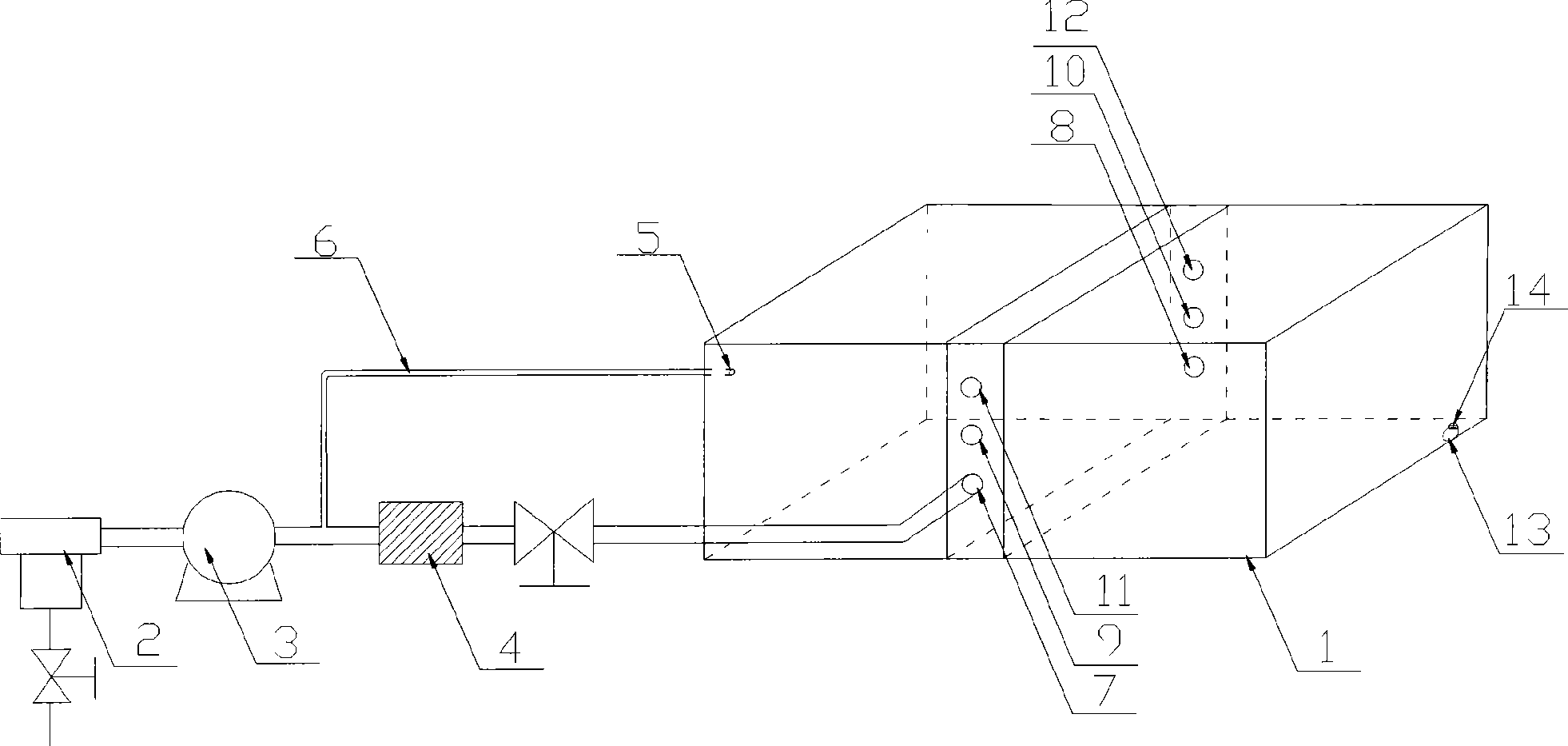

[0026] like figure 1As shown, a ventilation packaging method for a 50kw car fuel cell stack includes a closed packaging frame 1, which encapsulates all parts of the fuel cell stack, and the packaging frame 1 is provided with The air pipe inlet 7, air pipe outlet 8, hydrogen pipe inlet 9, hydrogen pipe outlet 10, cooling water pipe inlet 11, and cooling water pipe outlet 12 corresponding to each fluid inlet and outlet pipe of the stack, the air system of the fuel cell includes air Supply device, air humidification stack 4, fuel cell stack, the whole package is sealed outside the fuel cell stack, the air supply device includes a filter 2 and a blower 3, the air is filtered from the filter 2 , is input by blower 3, and enters the fuel cell stack after being humidified by air humidifier 4. The panel side of the closed packaging frame 1 is provided with a vent 5, and the vent 5 is connected to the fuel cell through a vent pipe 6. The air blower 3 outlet of the air supply device, t...

Embodiment 2

[0029] see figure 1 A ventilation packaging method for a fuel cell stack used in a 100kw city bus, comprising a closed packaging frame, which encapsulates all the components of the fuel cell stack, and the packaging frame is provided with fluids connected to the stack The air pipe inlet, the air pipe outlet, the hydrogen pipe inlet, the hydrogen pipe outlet, the cooling water pipe inlet, and the cooling water pipe outlet corresponding to the inlet and outlet pipes, the air system of the fuel cell includes an air supply device, an air humidification stack, a fuel cell electrical stack, the whole package is sealed outside the fuel cell stack. The air supply device includes a filter and a blower. A battery stack, one side of the panel of the closed packaging frame is provided with a vent, one end of the ventilation pipe is connected to the vent on the closed packaging frame, and the other end is connected to the pipeline between the blower and the air humidification stack, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com