Water-proof wiring harness and manufacture method thereof

A production method and waterproof thread technology, applied in the direction of cable/conductor manufacturing, conductors, insulated cables, etc., can solve problems such as low success rate, heavy workload, and product leakage, and achieve simple operation, low material cost, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] as attached Figure 8 A specific implementation of the shown method for making a waterproof wire harness includes the following steps:

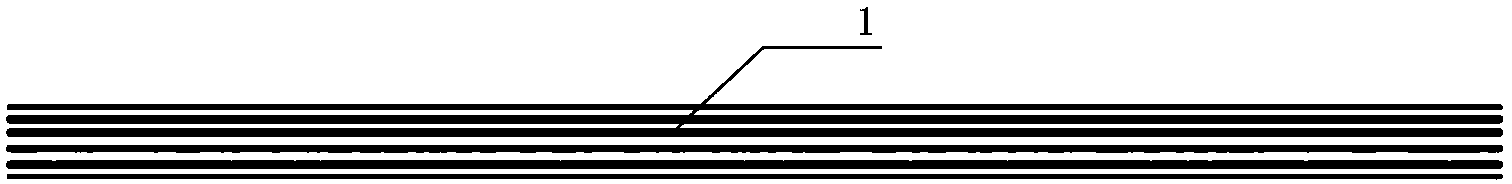

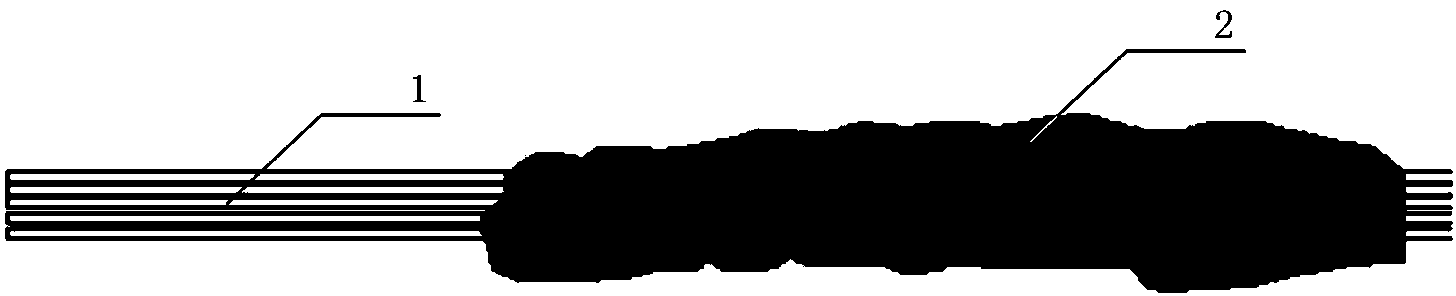

[0040] S10: coating the inner filler 2 on the outer surface of the wire harness 1 that needs to pass through the sealed cavity 5;

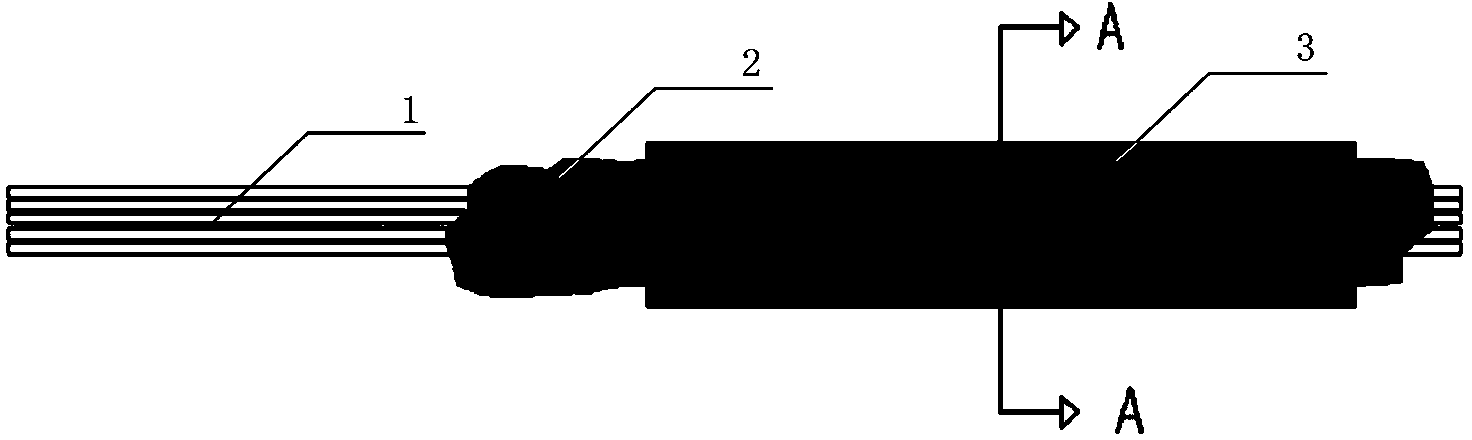

[0041] S20: Select an outer wrapping 3 with a suitable inner diameter, and put it on the inner filler 2;

[0042] S30: as attached Figure 5 As shown, the outer wrapping 3 is heated, and the outer wrapping 3 shrinks when heated, thereby extruding the inner filler 2, so that the inner filler 2 fully penetrates into the gap between the wire harnesses 1, as shown in the attached Image 6 Shown is a B-B cross-sectional schematic diagram of the waterproof wire harness during the heating process;

[0043] S40: Put the wire harness 1 treated above into the inside of the sealed cavity 5, and use the cable clamp 4 to lock the wire harness 1 wrapped with the outer wrapping 3.

[0044] As a preferred embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com