Two-component cement-based polymer rigid waterproof mortar

A rigid waterproof, cement-based technology, applied in infrastructure engineering, building components, protective devices, etc., can solve problems such as the influence of bonding performance, high slurry viscosity, and affecting construction speed, and achieve good waterproof and bonding performance Excellent and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

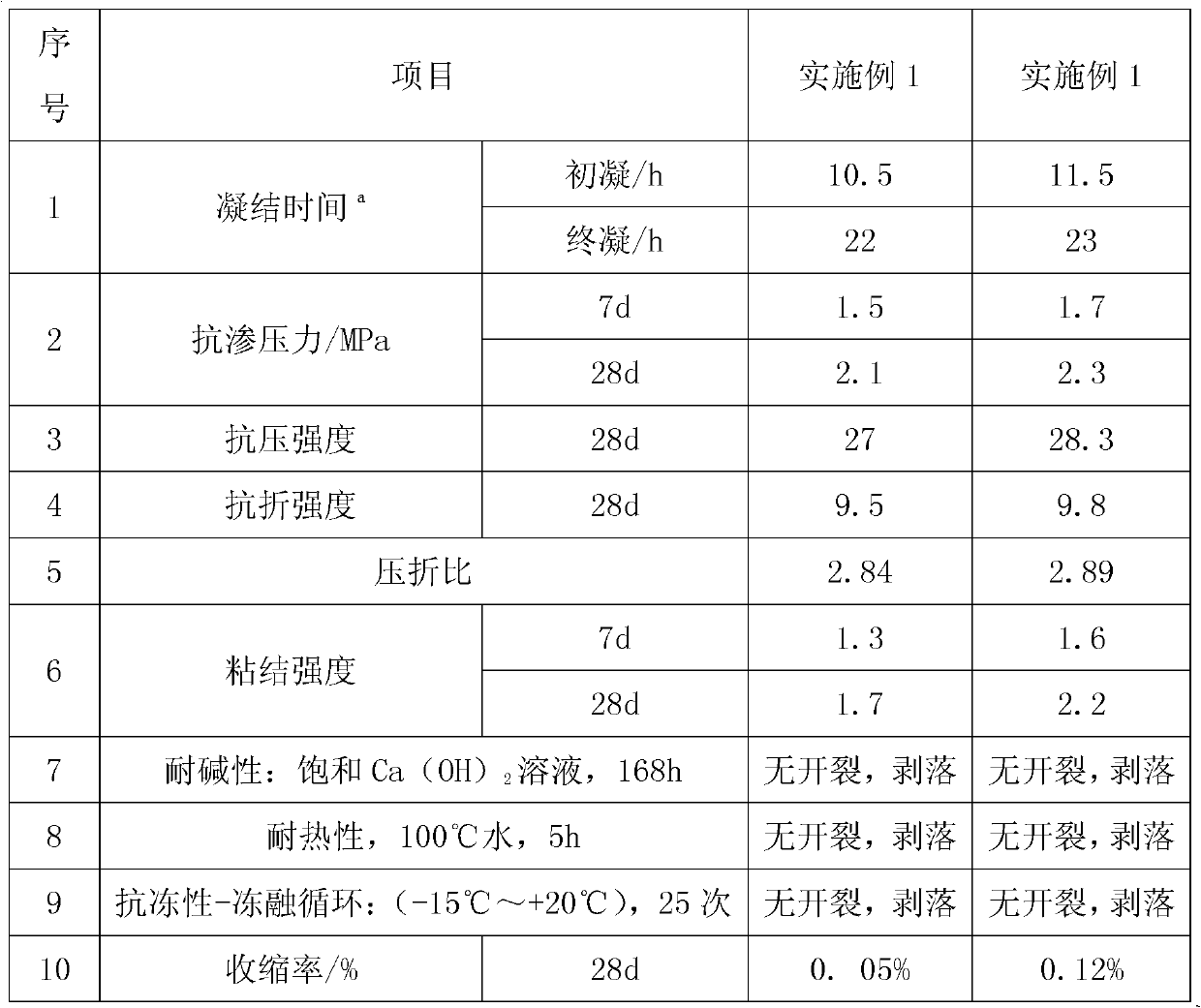

Examples

Embodiment 1

[0034] 1) Liquid material part

[0035] Butadiene-styrene copolymer emulsion 8.00%;

[0036] Styrene-acrylate copolymer emulsion 6.00%;

[0037] Coalescing aid 0.10%;

[0038] Defoamer 0.40%;

[0039] Water 85.50%;

[0040] 2) Powder part

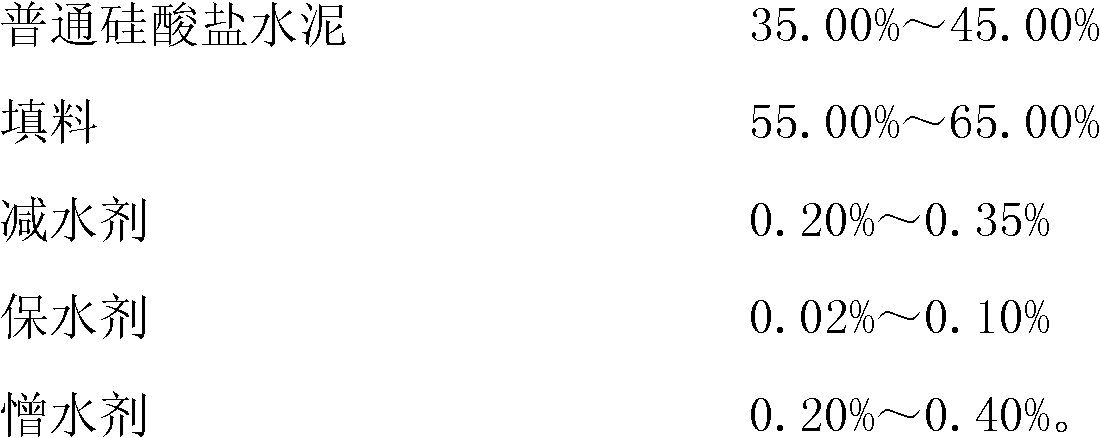

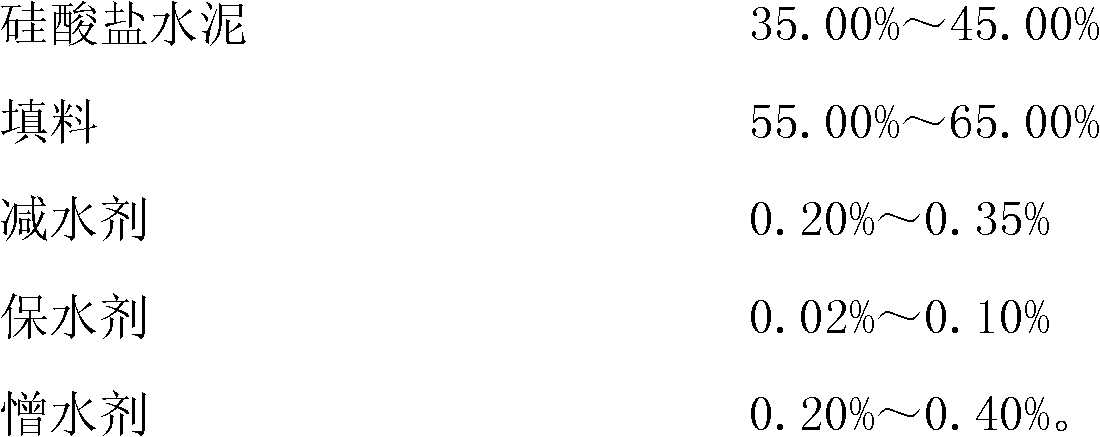

[0041] Ordinary Portland cement 35.00%;

[0042] Filler 64.38%;

[0043] Water reducer 0.20%;

[0044] Water retaining agent 0.02%;

[0045] Hydrophobic agent 0.40%;

[0046] Retarder 0.00%;

[0047] Tackifier 0.00%.

Embodiment 2

[0049] 1) Liquid material part

[0050] Butadiene-styrene copolymer emulsion 12.00%;

[0051] Styrene-acrylate copolymer emulsion 5.30%;

[0052] Coalescing aid 0.50%;

[0053] Defoamer 0.20%;

[0054] Water 82.00%;

[0055] 2) Powder part

[0056] Ordinary Portland cement 44.09%;

[0057] Filler 55.00%;

[0058] Water reducer 0.35%;

[0059] Water retaining agent 0.10%;

[0060] Hydrophobic agent 0.40%;

[0061] Retarder 0.01%;

[0062] Tackifier 0.05%.

Embodiment 3

[0064] 1) Liquid material part

[0065] Butadiene-styrene copolymer emulsion 12.00%;

[0066] Styrene-acrylate copolymer emulsion 2.00%;

[0067] Coalescing aid 0.30%;

[0068] Defoamer 0.30%;

[0069] Water 85.4%;

[0070] 2) Powder part

[0071] Ordinary Portland cement 45.00%;

[0072] Filler 54.43%;

[0073] Water reducer 0.35%;

[0074] Water retaining agent 0.02%;

[0075] Hydrophobic agent 0.20%;

[0076] Retarder 0.00%;

[0077] Tackifier 0.00%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com