Matt prevention film waterborne matt varnish and preparation method thereof

A matte film, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as low strength and easy bursting, and achieve the effects of easy construction, excellent flexibility, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

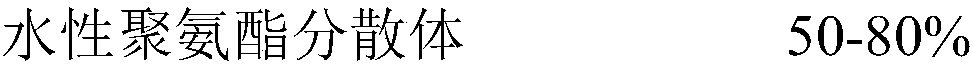

[0024] A water-based matte oil for an anti-matte film, which consists of the following components according to mass percentage:

[0025]

[0026] The water-based polyurethane emulsion refers to a water-based aliphatic polyurethane dispersion with excellent flexibility, the elongation rate is greater than 300%, the tensile strength is greater than 40MPa, the solid content is 34-36%, and the pH value is 7-9.

[0027] The self-crosslinking acrylic emulsion refers to an aqueous acrylic emulsion with self-crosslinkable functional groups, with a Tg value of 10° C. and a solid content of 45%.

[0028] The matting powder is silica matting powder, specifically AZ-200 matting powder of Tosoh Corporation.

[0029] Described water-based wax emulsion is a high-density polyethylene wax emulsion, specifically KEIM's MD-2000.

[0030] The wetting agent is polysiloxane polyether copolymer, specifically TEGO Twin4100 from Tego Company.

Embodiment 2

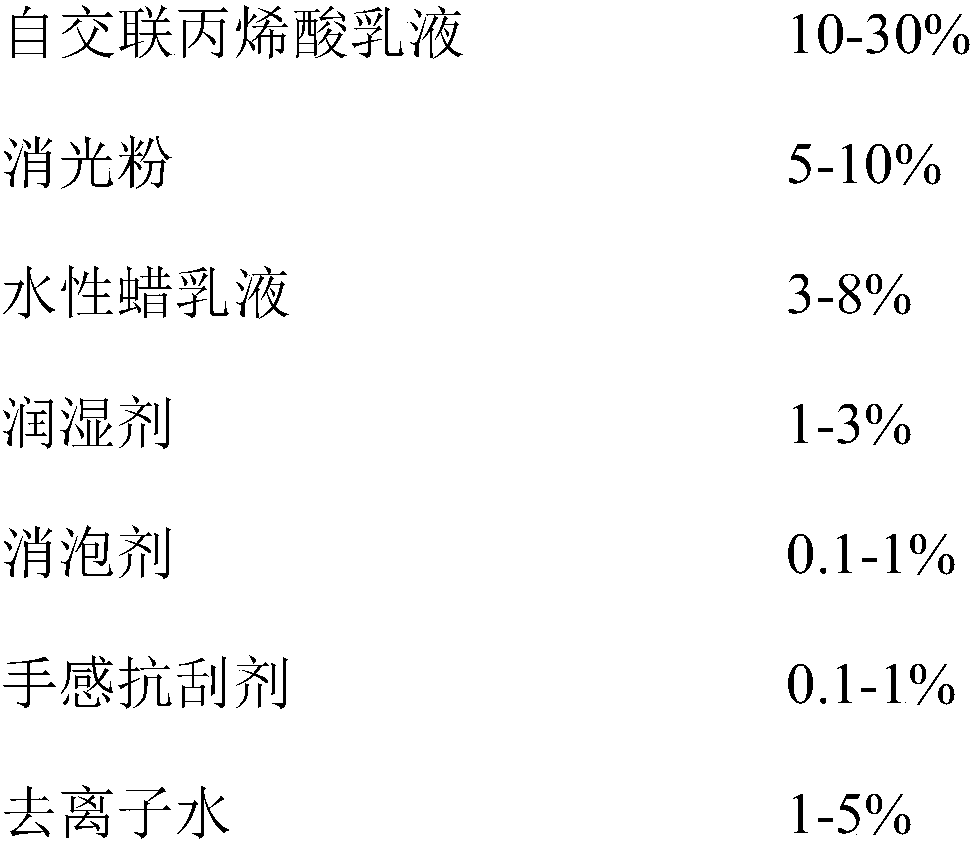

[0038] A water-based matte oil for an anti-matte film, which consists of the following components according to mass percentage:

[0039]

[0040] The water-based polyurethane emulsion refers to a water-based aliphatic polyurethane dispersion with excellent flexibility, the elongation rate is greater than 300%, the tensile strength is greater than 40MPa, the solid content is 34-36%, and the pH value is 7-9.

[0041] The self-crosslinking acrylic emulsion refers to an aqueous acrylic emulsion with self-crosslinkable functional groups, with a Tg value of 10° C. and a solid content of 45%.

[0042] The matting powder is silica matting powder, specifically AZ-200 matting powder of Tosoh Corporation.

[0043] Described water-based wax emulsion is a high-density polyethylene wax emulsion, specifically KEIM's MD-2000.

[0044] The wetting agent is polysiloxane polyether copolymer, specifically TEGO Twin4100 from Tego Company.

[0045] The defoamer is a silicone defoamer, specif...

Embodiment 3

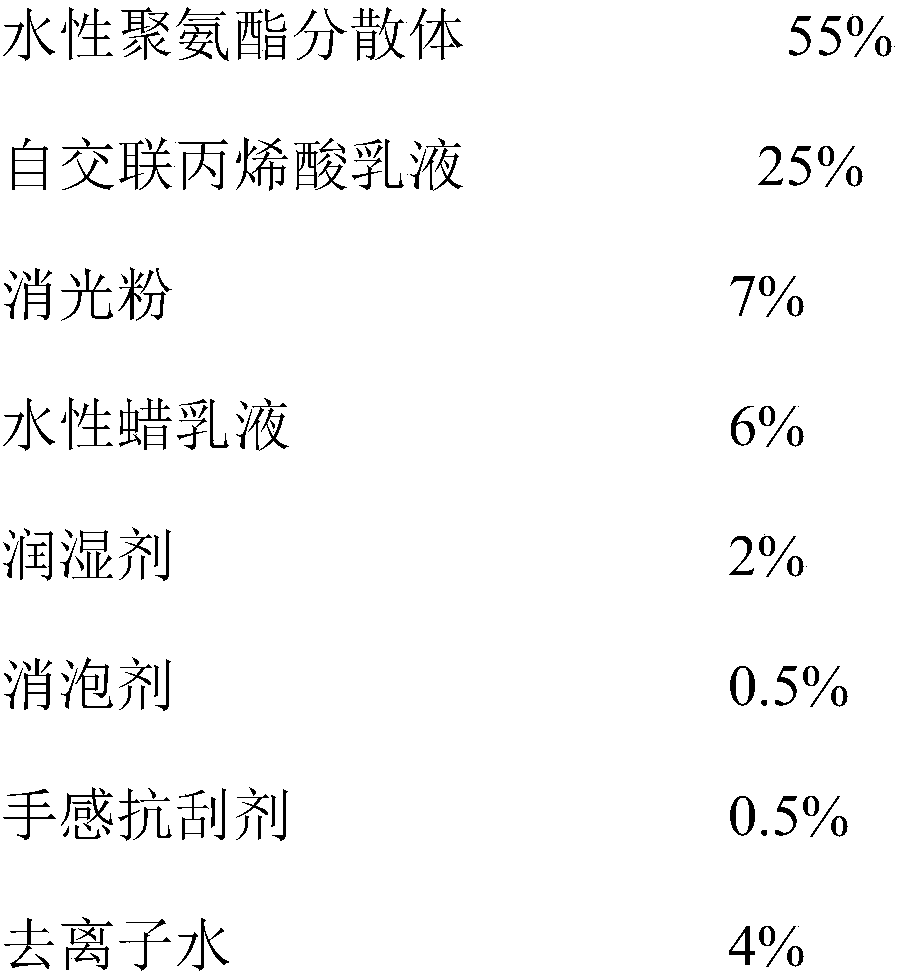

[0052] A water-based matte oil for an anti-matte film, which consists of the following components according to mass percentage:

[0053]

[0054]

[0055] The water-based polyurethane emulsion refers to a water-based aliphatic polyurethane dispersion with excellent flexibility, the elongation rate is greater than 300%, the tensile strength is greater than 40MPa, the solid content is 34-36%, and the pH value is 7-9.

[0056] The self-crosslinking acrylic emulsion refers to an aqueous acrylic emulsion with self-crosslinkable functional groups, with a Tg value of 10° C. and a solid content of 45%.

[0057] The matting powder is silica matting powder, specifically AZ-200 matting powder of Tosoh Corporation.

[0058] Described water-based wax emulsion is a high-density polyethylene wax emulsion, specifically KEIM's MD-2000.

[0059] The wetting agent is polysiloxane polyether copolymer, specifically TEGO Twin4100 from Tego Company.

[0060] The defoamer is a silicone defoam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com