Auxiliary transferring equipment for textile production

A technology of equipment and support columns, which is applied in the field of auxiliary transfer equipment for textile production, can solve problems such as damage to textile fabrics, affecting the quality of fabrics, and mutual collisions, and achieves the effects of prolonging service life, reducing manual labor, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

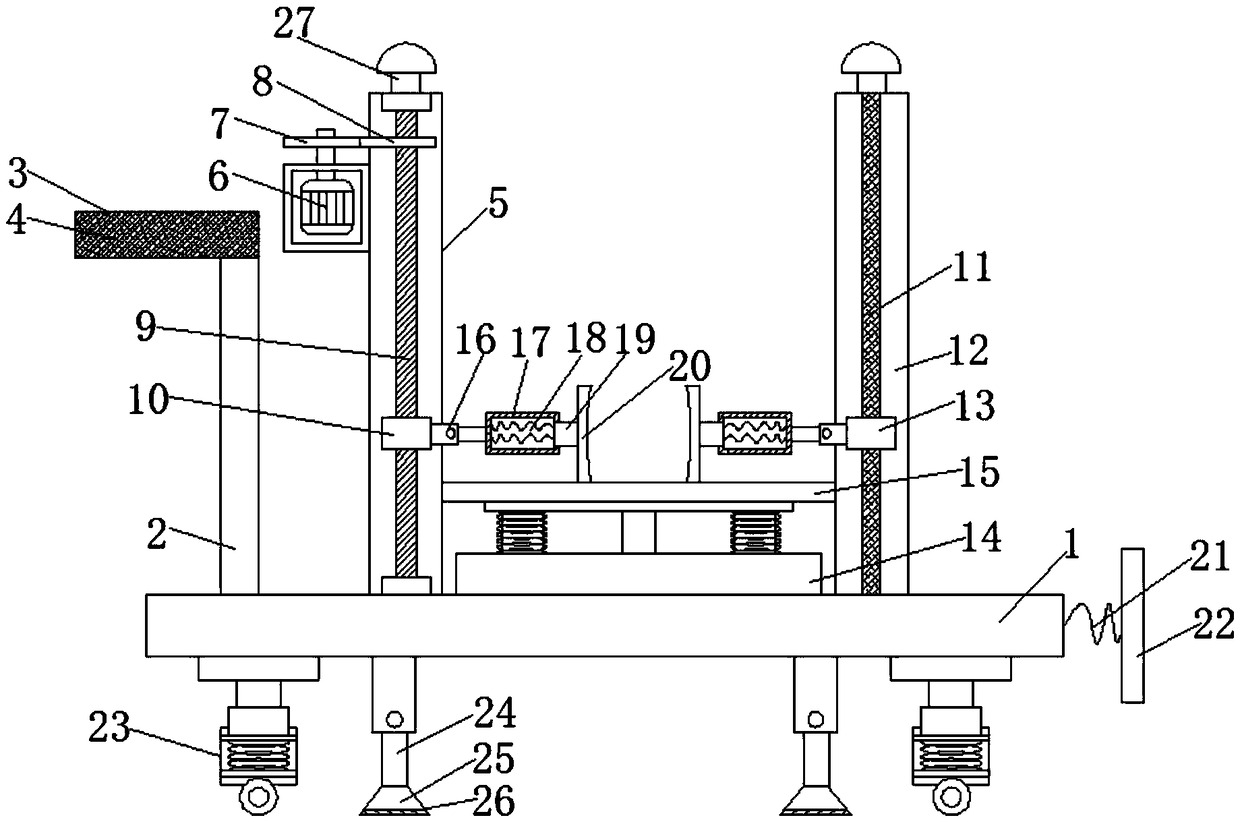

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

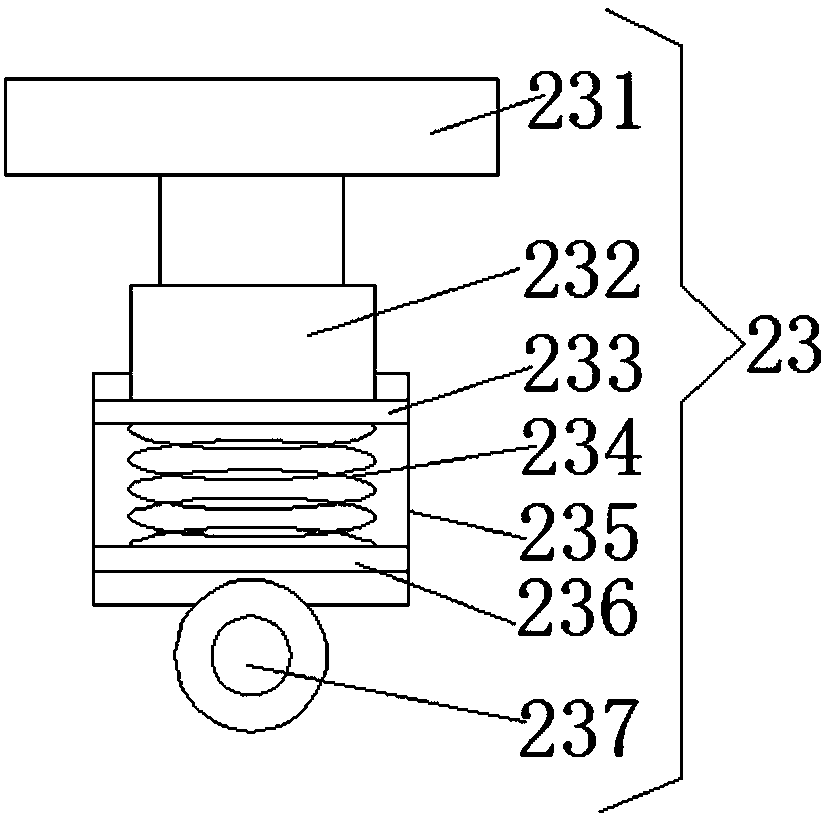

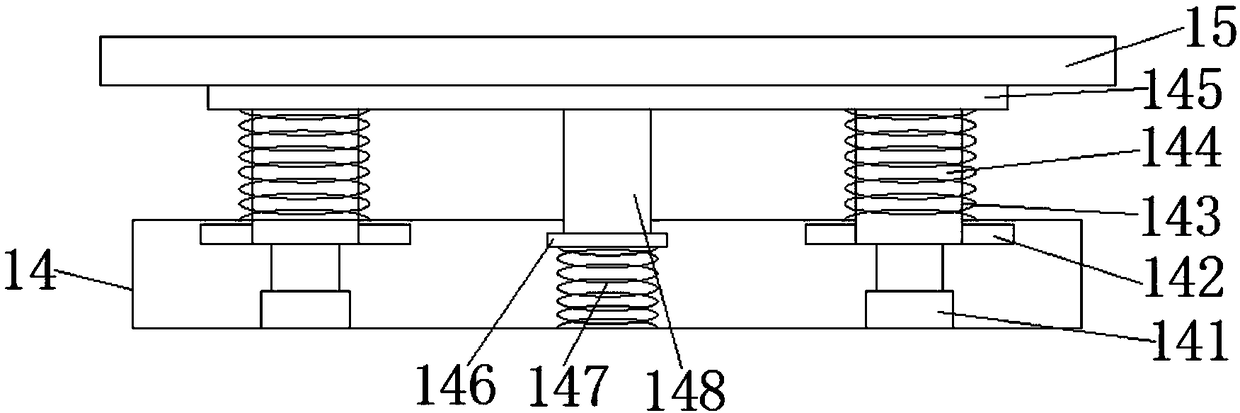

[0023] An embodiment of the present invention provides an auxiliary transfer device for textile production, such as Figure 1-3As shown, including the base 1, the bottom of the base 1 is fixedly equipped with a second electric telescopic rod 24, and the bottom of the second electric telescopic rod 24 is fixedly equipped with a support frame 25, and the number of the support frame 25 is four, and the bottom of the support frame 25 An anti-slip mat 26 is fixedly installed. By setting the anti-slip mat 26, the anti-slip mat 26 can increase the friction with the ground, improve the stability of the device, and prevent movement during the handling of textile fabrics, which will affect the work and use, and affect the handling efficiency. To improve the working efficiency of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com