Pneumatic lever type clamping structure

A lever-type and fixture technology, which is applied in clamping, manufacturing tools, supports, etc., can solve the problems of different sizes, different loading and unloading methods, and large locking force, so as to achieve stable processing cycle, improve processing accuracy, and use safely. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

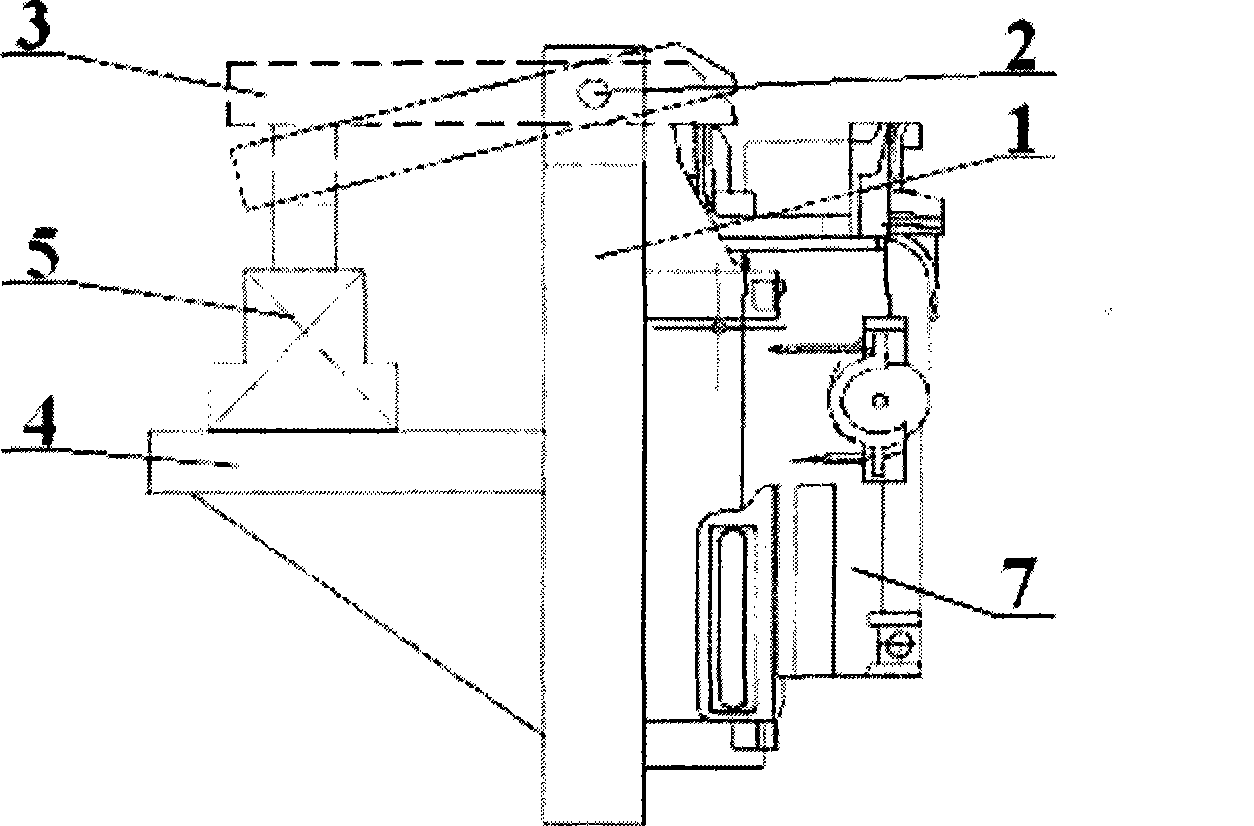

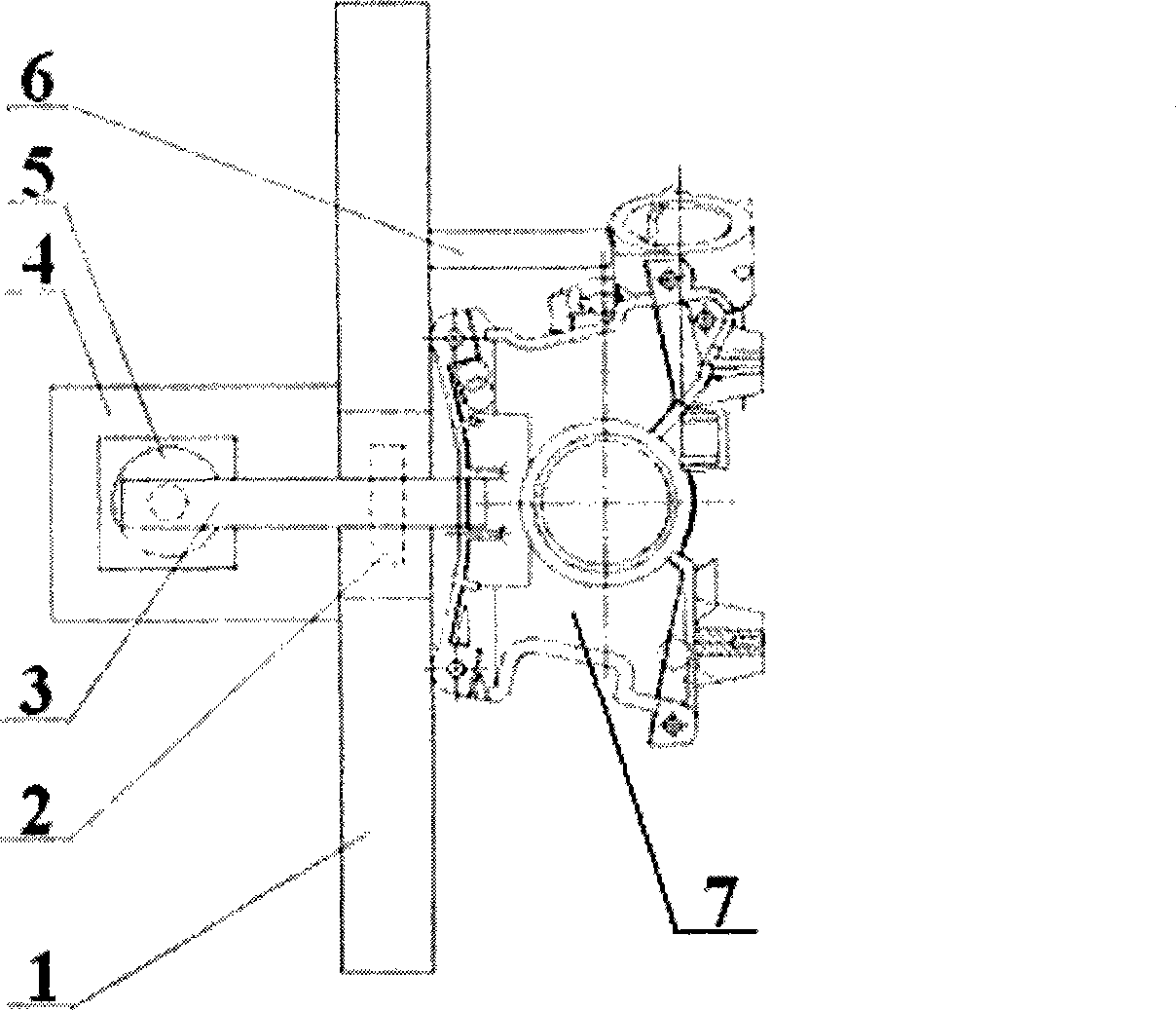

[0023] The distance between the lever fulcrum 2 of the present invention and the connection position between the pressure plate 3 and the cylinder 5 is the arm of force; the distance between the lever fulcrum 2 and the contact position between the pressure plate 3 and the workpiece 7 is the action arm; the length of the force arm is greater than The length of the action arm.

[0024] In increasing the fast clamping effect on the workpiece, the leverage principle is used to increase the force of the cylinder.

Embodiment 2

[0026] When the pressing plate 3 of the present invention clamps the workpiece 7, the end point of the cylinder 5 pushes the force arm to move upward, that is, the workpiece 7 is below the force arm.

[0027] Depend on figure 1 , figure 2 Visible, the using method of the present invention is: first the steering wheel steering column is clamped on the clamp body 1; The cylinder 5 exerts a force on the pressure plate 3 with the lever fulcrum 2 as the fulcrum, thereby effectively limiting the vertical freedom of the steering column Z axis and fixing its processing position.

[0028] This kind of pneumatic lever clamp structure uses an external cylinder to design a lever fulcrum between the workpieces to be processed, so that the work done by the external cylinder can generate enough force to quickly clamp the workpiece through the formed active arm. If such light alloy castings are processed by modern CNC machine tools, this pneumatic lever clamp structure is very practical an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com