Whirl entraining type cooking fume exhauster

A range hood and swirl tank technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of low efficiency of oil fume suction and exhaust, easy to block the line of sight, poor air flow, etc., and achieve the improvement of oil fume extraction rate, Mutual interference is eliminated and the function does not degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

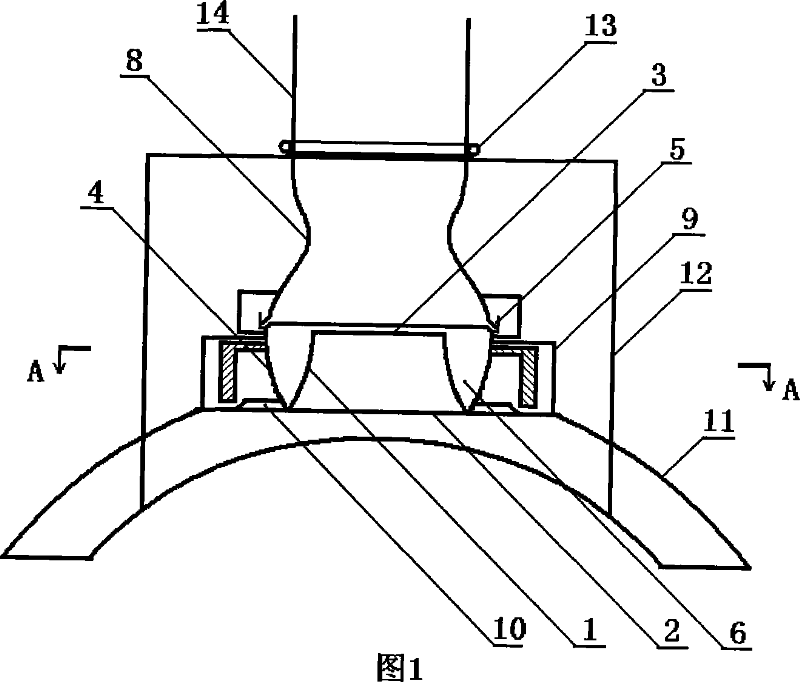

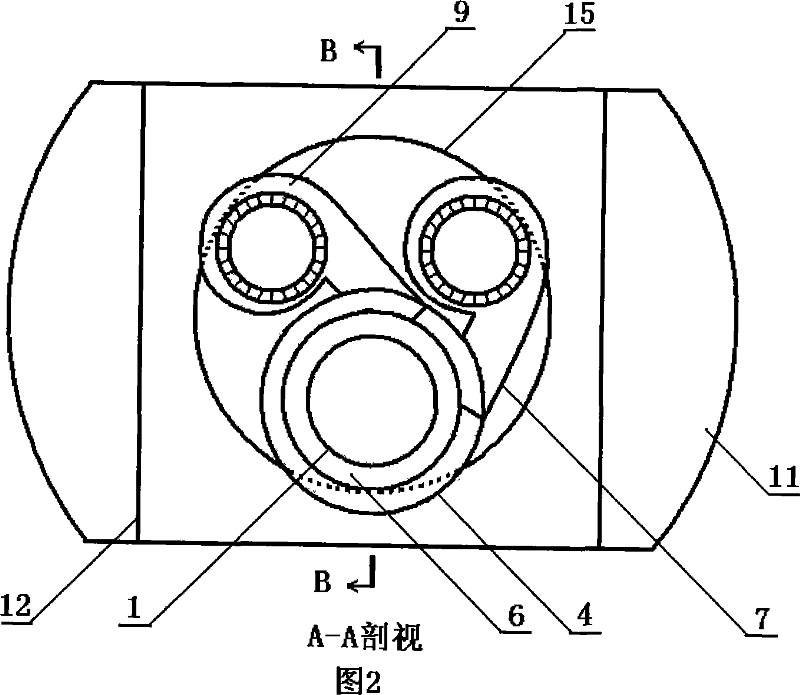

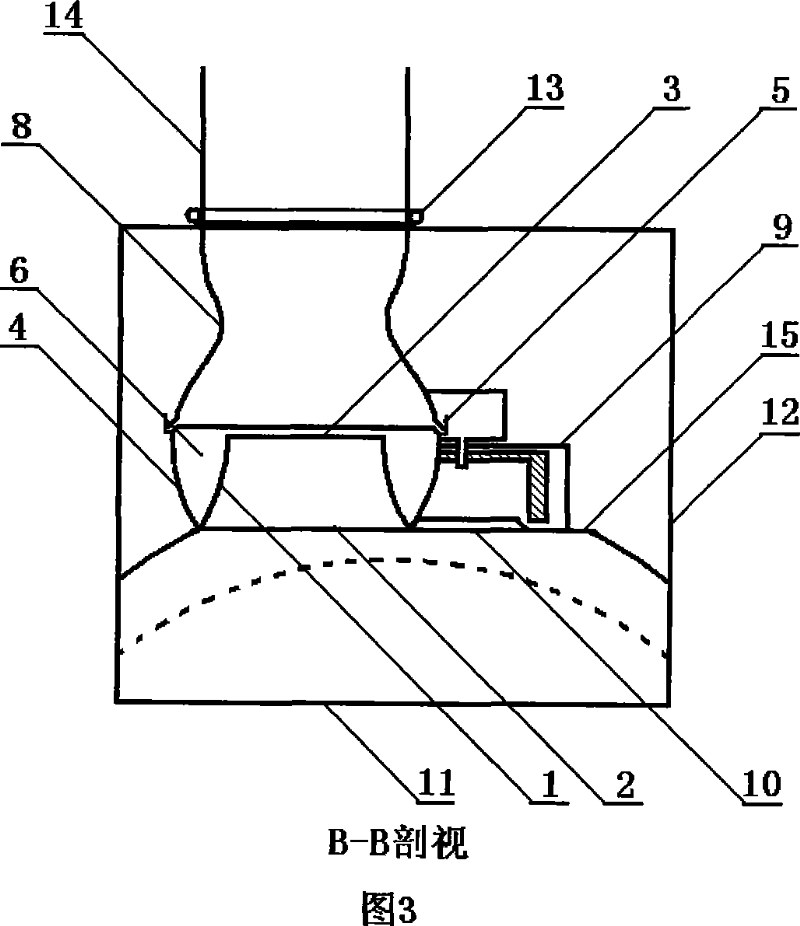

[0027] This embodiment is an implementation manner of a swirling flow range hood. Fig. 1 is a schematic diagram of its longitudinal sectional structure, Fig. 2 is a schematic diagram of the A-A sectional structure of Fig. 1 , and Fig. 3 is a schematic diagram of the B-B sectional structure of Fig. 2 .

[0028] As shown in Fig. 1, Fig. 2 and Fig. 3: the swirling oil fume suction device adopted in this embodiment is a sleeve-shaped device, that is, the trumpet-shaped inner cylinder 1 with the central axis extends into the outer cylinder 4, An annular swirl groove 6 with a "v" shape in cross section and a sealed groove bottom is formed. The generatrix of the inner tube 1 of the horn is hyperbolic, the diameter of the lower opening is 1.25 times the diameter of the upper opening 3, and the height is 1.25 times that of the upper opening 3. 0.5 times the diameter of the mouth 3, the generatrix of the outer cylinder 4 is parabolic, the diameter of the upper opening is 1.2 times the d...

Embodiment 2

[0034] This embodiment is another implementation of the swirling flow range hood. Fig. 4 is a schematic view of its longitudinal section structure, Fig. 5 is a schematic view of a C-C sectional structure of Fig. 4 , and Fig. 6 is a schematic view of a D-D sectional structure of Fig. 5 .

[0035] As shown in Fig. 4, Fig. 5 and Fig. 6: the structure and connection mode of the swirling oil fume suction device, the annular oil cut-off groove 5, and the double-sided sealed rolling door 13 adopted in this embodiment are the same as those in embodiment 1, and the difference The location is: the spherical smoke collecting hood 11 is installed in an inclined and low position, so that the smoke collecting hood 11 has a low smoking port 16 that is closer to the stove, and the corresponding smoking port 2 that is farther from the stove is a high smoking port. Under the air inlet 10 of the blower fan, a draft guide tube 17 is stretched out and connected to the low-position smoke opening 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com