Air curtain kitchen fumes ventilator

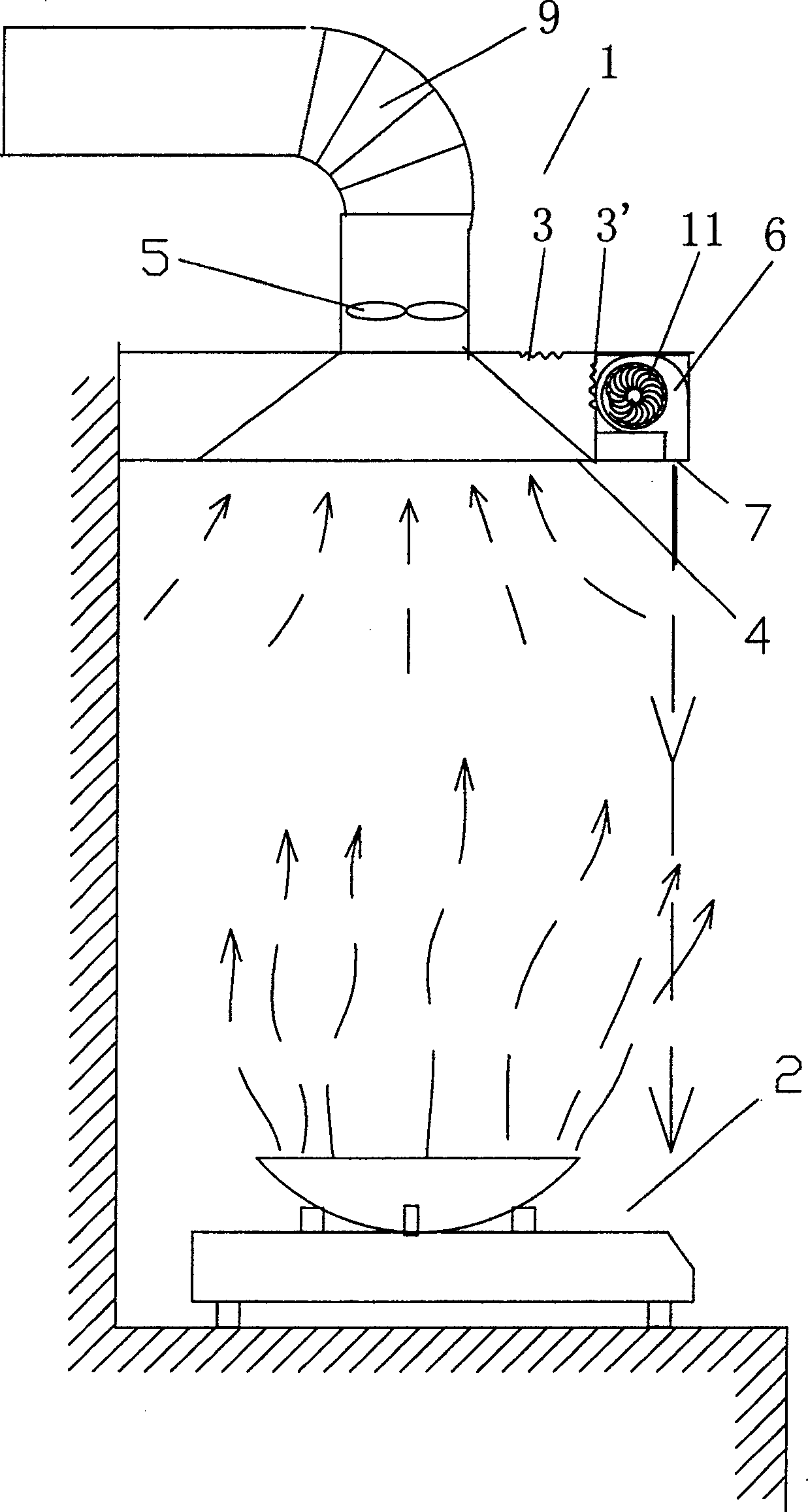

A range hood and air curtain technology, which is applied in the field of air curtain range hood suction and exhaust, can solve the problems of increasing the complexity of the structure, weakening the effect of the air curtain, and not being able to assist the extraction of oil fume, so as to prevent damage to human health and prevent floating Divergent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

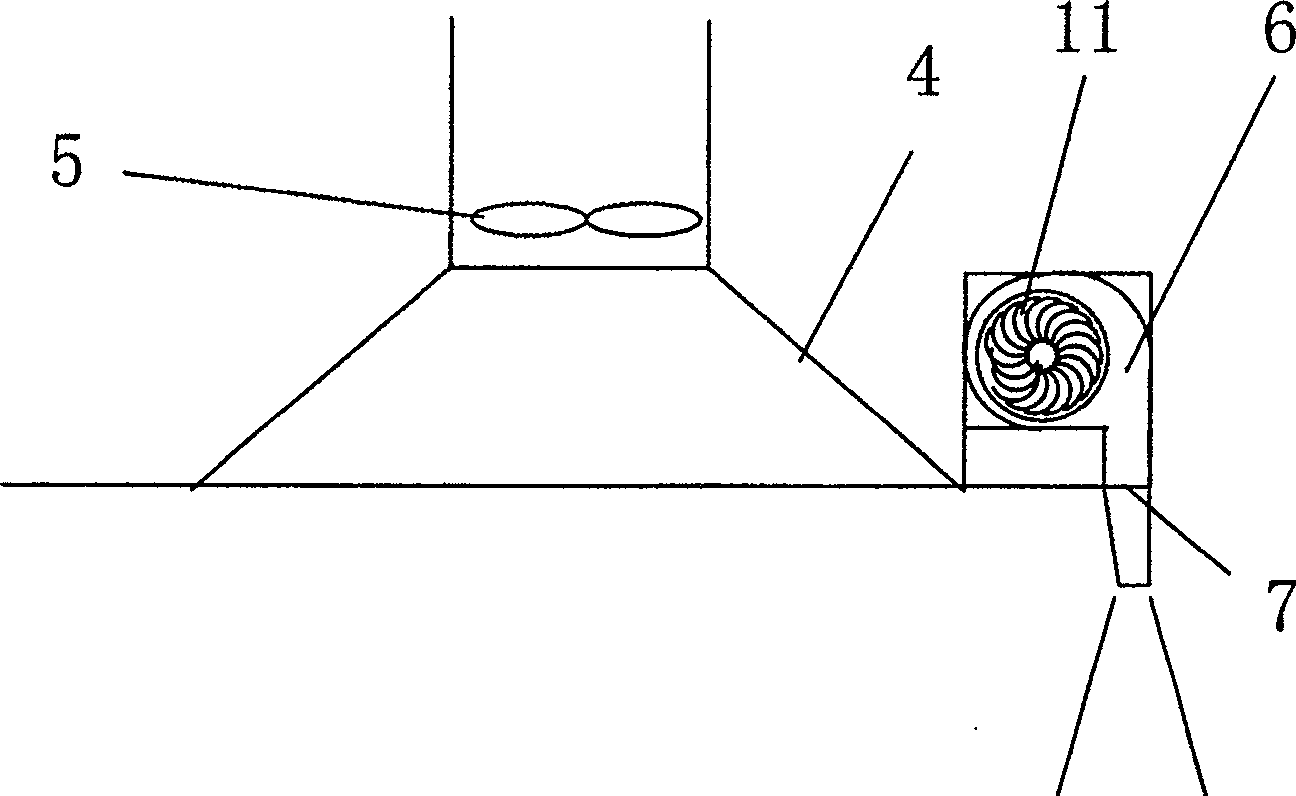

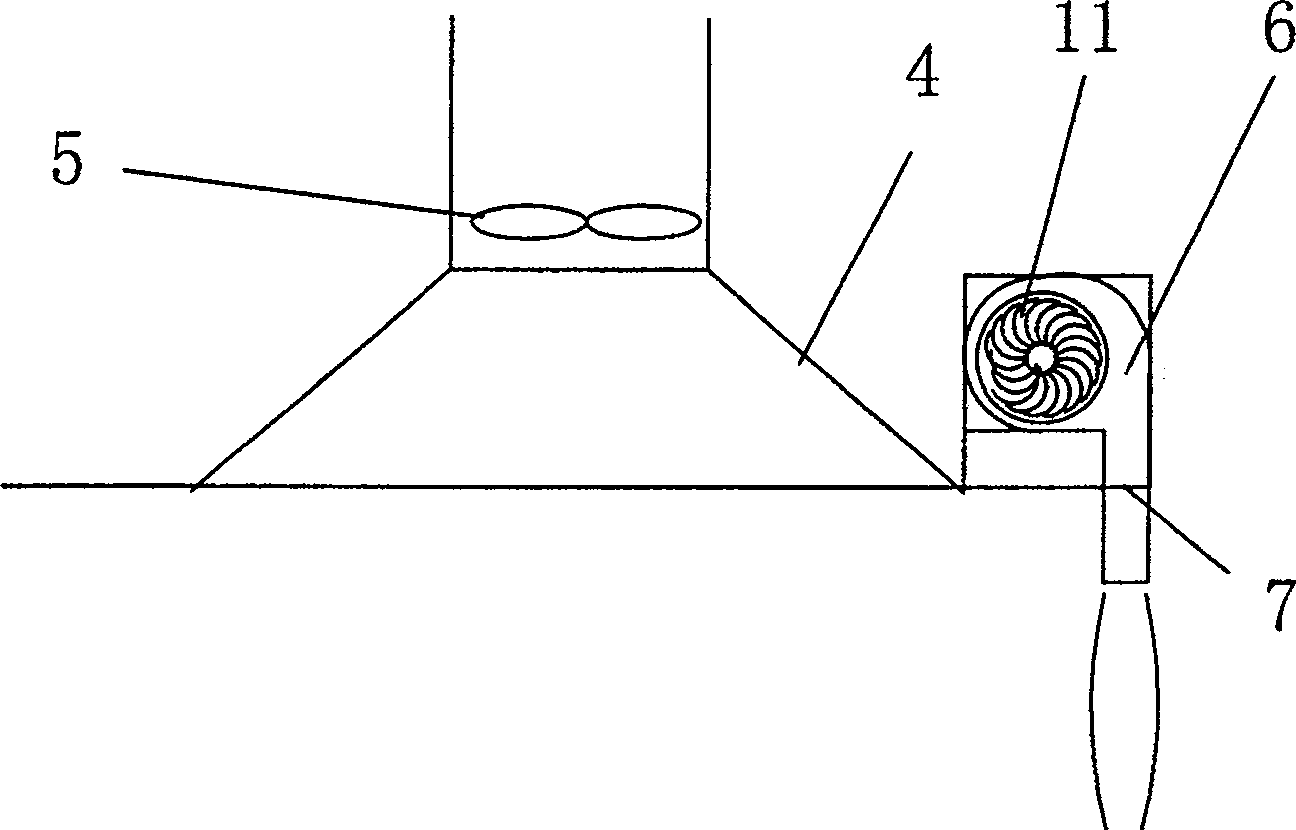

Embodiment 1

[0055] Figure 5 (a) shows an embodiment of the air supply opening with an inwardly expanding inner side, in which: on the bottom wall of the smoke collecting hood 4 at the lower inner side of the air supply opening, a curved baffle 8 is provided; in Figure 5 (a) In the specific embodiment shown in (a), the arc-shaped deflector is a semi-arc deflector, and the deflector can be injection molded into a hollow plastic or metal part. The deflector 8 is curved downward from the air supply cavity 6 and toward the inner working area of the smoke collecting hood. The tangent direction of the deflector toward the air supply port is 5-35° from the vertical. Is 5-10°. The outer side wall 10 of the air supply outlet is a vertical plane, preferably set as a plane inclined toward the working area, and the angle between the outer side wall inclined toward the inside of the hood and the vertical plane is 5-20°, preferably Is 5-10°. The purpose of this arrangement is to make the wind curtain incl...

Embodiment 2

[0057] Figure 5(d) shows a second embodiment of the air outlet with an inwardly expanding inside, in which: on the bottom wall of the smoke collecting hood 4 at the lower part of the air outlet, a curved baffle 8 is provided; in the figure In the specific embodiment shown in 5(d), the curved baffle is a semi-circular arc baffle, and the baffle 8 is curved downward from the air supply cavity 6 and toward the inside of the smoke collecting hood. , The tangent direction of the arc surface of the baffle facing the air supply opening is 5-35°, preferably 5-10° from the vertical. The outer side wall 11 of the air supply port is a vertical plane, and is preferably set as a plane inclined toward the inside of the hood. The angle between the outside side wall inclined toward the inside of the hood and the vertical plane is 5-20°, preferably It is 5-10°, the outer side wall 11 extends downward from the end of the smoke collecting hood 4 to the lower end of the curved baffle, and the plane o...

Embodiment 3

[0059] Figure 5(e) shows a third embodiment of the air supply opening with an inwardly expanding inside, in which: on the bottom wall of the smoke collecting hood 4 at the lower part of the air supply opening, a curved baffle 8 is provided; in the figure In the specific embodiment shown in 5(e), the arc-shaped baffle is a 1 / 4 arc baffle, and the baffle 8 is formed downward and toward the inside of the smoke collecting hood from the air supply cavity 6 The arc surface is curved, and the tangent direction of the arc surface of the deflector toward the air supply opening is 5-35°, preferably 5-10° from the vertical. The outer side wall 10 of the air supply port is a flat surface, and is preferably set as a plane inclined toward the inside of the hood. The angle between the outside side wall slanted toward the inside of the hood and the vertical plane is 5-20°, preferably 5-10°. The purpose of this setting is to make the wind curtain inclined inward to facilitate the formation of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com