Oil fume guide type range hood

A technology for range hood and range hood is applied in the field of range hood, which can solve the problems of narrowness, reduced exhaust volume of household range hood, and weakened suction effect, and achieves the effects of speeding up flow, preventing outward diffusion, and facilitating discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

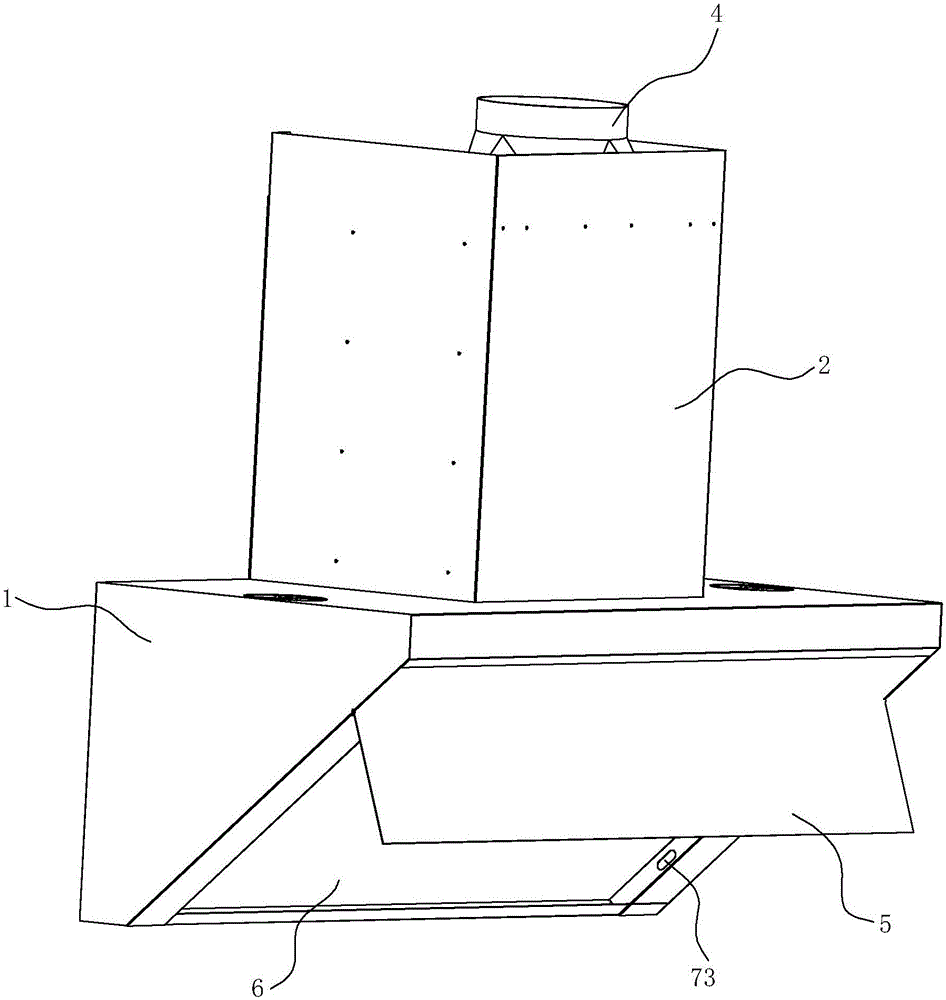

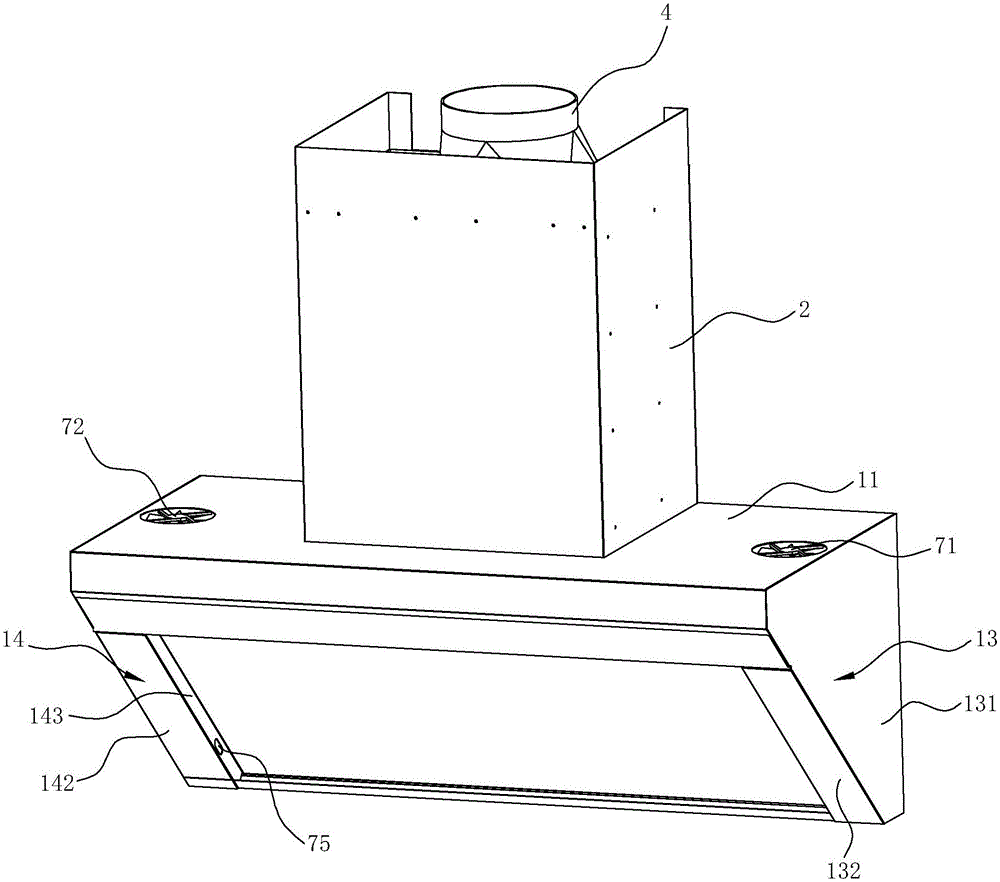

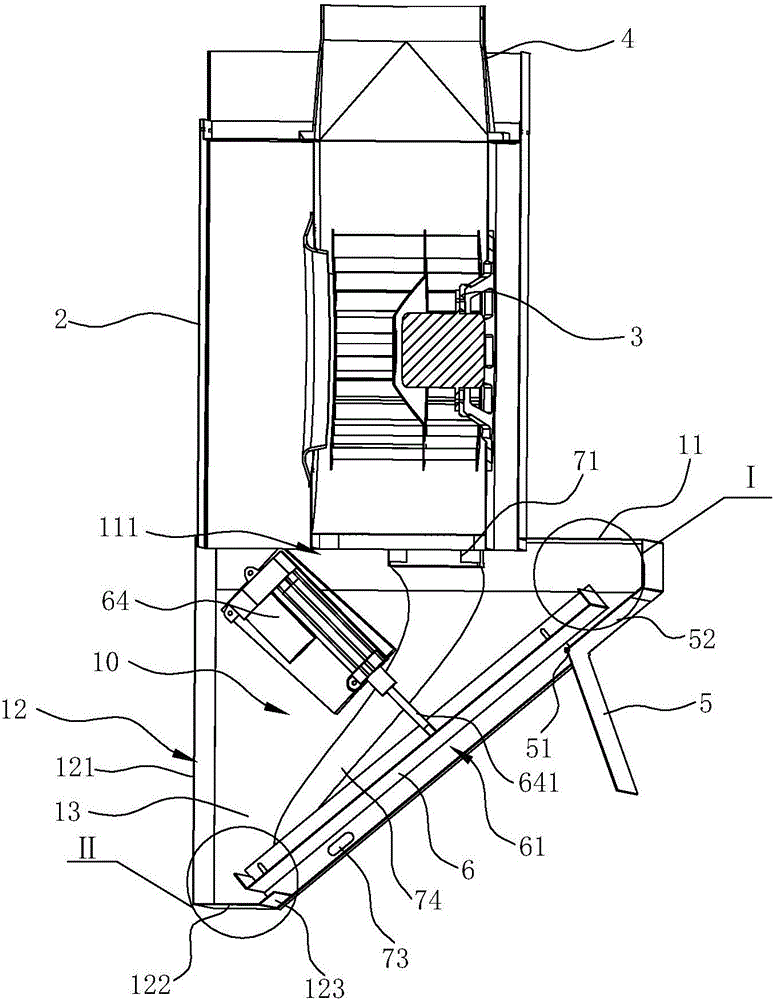

[0032] see Figure 1 ~ Figure 4 , an oil fume guiding type range hood, comprising a smoke collecting hood 1, and a fan cover 2 located above the smoke collecting hood 1, a fan 3 is arranged inside the fan cover 2, and is used to suck the oil fume into the range hood and pass it through the fan The air outlet cover 4 on the top of the cover 2 is discharged to the public flue.

[0033] For the convenience of description, "front", "rear", "left", and "right" below refer to the orientation of the range hood relative to the user when the range hood is in use. The shell of the fume collecting hood 1 includes a top plate 11 , a rear plate 12 , and a first side plate 13 and a second side plate 14 located on the left and right sides respectively. The back plate 12 is located at the back side of the top plate 11, the top of the back plate 12 is connected with the back side of the top plate 11, and the tops of the first side plate 13 and the second side plate 14 are respectively connect...

Embodiment 2

[0045] see Figure 9 and Figure 10 , in this embodiment, the difference from the first embodiment above is that the blower fan of the blowing and guiding device in the first embodiment sucks clean air from the outside of the range hood, while in this embodiment, the blowing and guiding device The device is arranged in the range hood, sucks the oil fume from the inside of the range hood and blows it out from the smoke guiding cavity 61 .

[0046] The first fan 71 and the second fan 72 are arranged on both sides of the smoke collecting chamber 10 , wherein the first fan 71 can be fixed to the first side plate 13 , and the second fan 72 can be fixed to the second side plate 14 . The first fan 71 is close to the first blowing port 73, and is connected to the first blowing port 73 through the first air guide 74, while the second fan 72 is close to the second blowing port 75, and is connected to the second blowing port 76 through the second wind guide 76. Air outlet 75. The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com