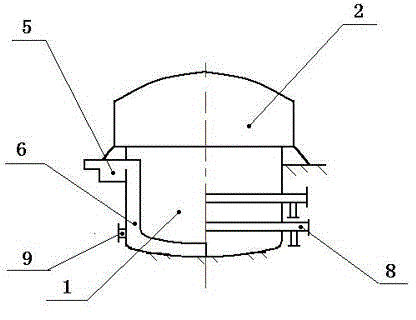

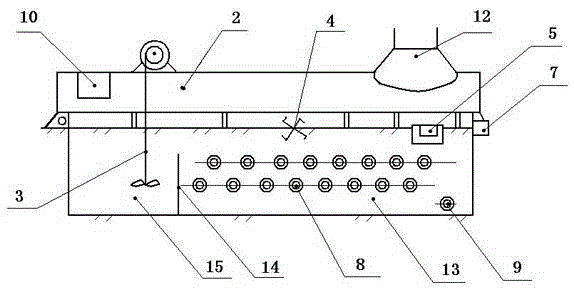

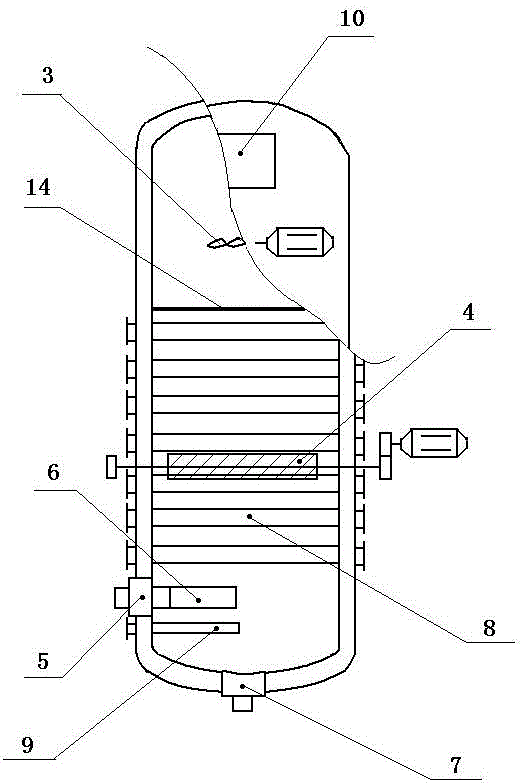

Device and method for continuously removing copper from liquid crude lead

A crude lead and liquid technology, which is applied in the field of devices for continuous copper removal of crude lead in liquid, can solve the problems of heat source, energy waste, high energy consumption, etc., and achieve the effects of reducing labor intensity, reducing environmental pollution, and reducing volatilization loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for continuously removing copper from liquid crude lead by using the device for continuous copper removal from liquid crude lead, comprising the following steps:

[0035] First, the liquid crude lead from the crude lead metallurgical furnace with a temperature above 600°C is continuously fed into the device for continuous copper removal of liquid crude lead through the chute from the feed port 10, and saw dust is continuously added from the feed port 10, vulcanized Lead, the addition ratio is the same as the conventional copper removal process, that is, the amount of saw foam added is 20~30Kg per ton of liquid hot lead, and the amount of lead sulfide added is based on the copper content in the liquid crude lead and the molar number of copper and sulfur is 2~3: 1 ratio added;

[0036] Then, the stirring of the mixer 3 makes the incoming liquid crude lead and the copper removal agent fully contact and react, so that the copper in the crude lead is converted into Cu...

Embodiment 2

[0040] A method for continuously removing copper from liquid crude lead by using the device for continuous copper removal from liquid crude lead, comprising the following steps:

[0041] First, the liquid crude lead from the crude lead metallurgical furnace with a temperature above 600°C is continuously fed into the device for continuous copper removal of liquid crude lead through the chute from the feed port 10, and at the same time, saw dust is continuously added from the feed port 10, oxidized Lead, the addition ratio is the same as the conventional copper removal process, that is, the addition amount of saw foam is 20~30Kg per ton of liquid hot lead, and the addition amount of lead oxide is 2~3 according to the copper content in liquid crude lead and the molar number of copper and oxygen: 1 ratio added;

[0042] Then, the stirring of the mixer 3 makes the incoming liquid crude lead and the copper removal agent fully contact and react, so that the copper in the crude lead i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com