Sealed hot blast cover device

A hot air cover and sealing brush technology, which is applied in engine sealing, waste heat treatment, lighting and heating equipment, etc., can solve the problems of staff and environmental hazards, and achieve the effects of ensuring safe operation, speeding up the exhaust sintering process, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

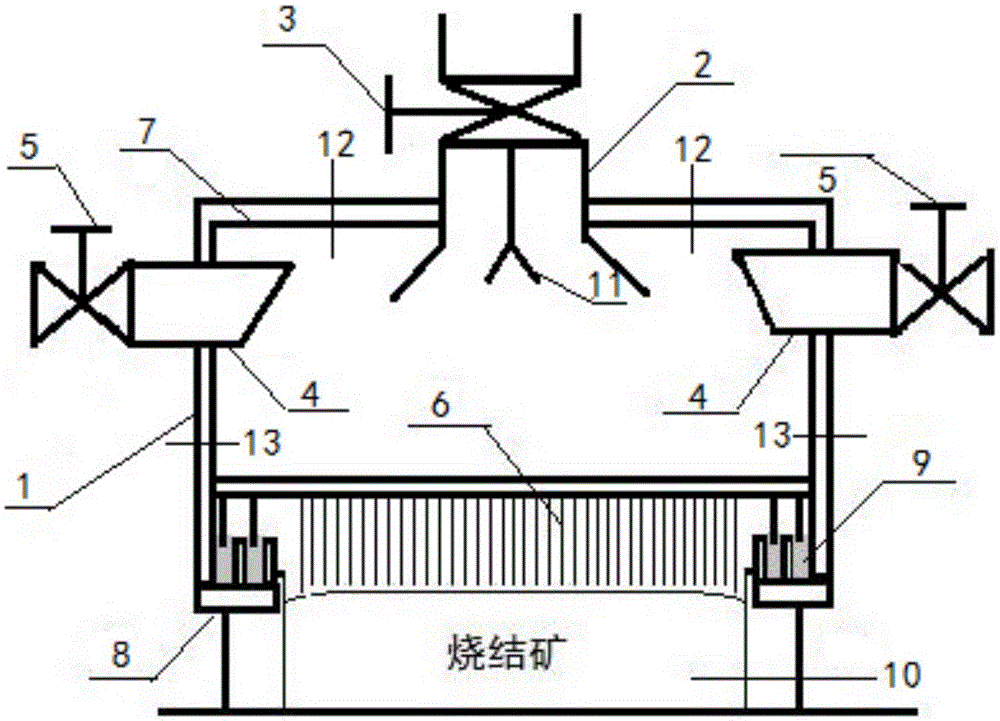

[0044] Embodiment 1: A kind of sealing hot air cover device

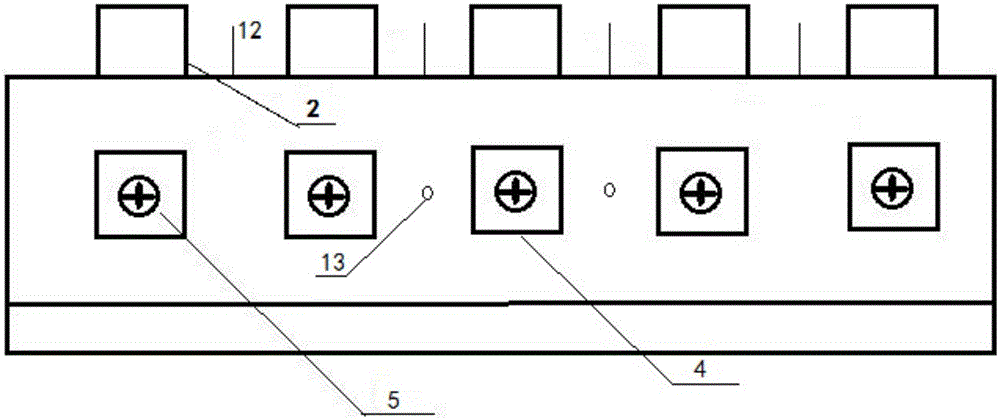

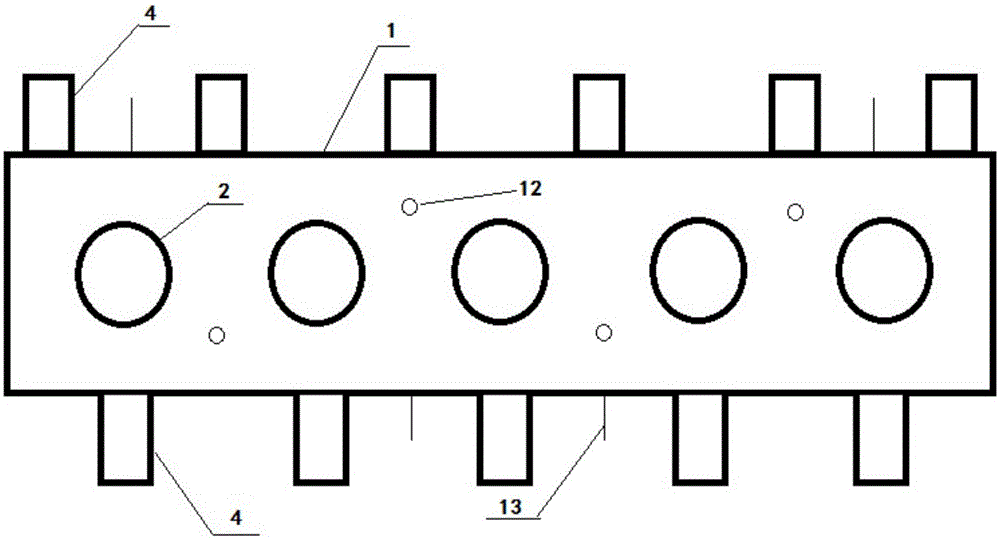

[0045] Such as figure 1 and figure 2 As shown in the schematic diagram of the sealed hot air hood device in the embodiment of the present invention, the gas hood 1 is installed on the part of the sintering machine that uses the circulating flue gas to cover the sintering machine, and several circulating air intake pipes are arranged on the top of the fume hood 1 2. A cut-off valve 3 is installed on the circulating air intake pipe 2, and a rectifier 11 is built in the circulating air intake pipe 2, and the opening of the rectifier 11 is expanded; Mid-fill thermal insulation mineral wool;

[0046] Emergency ventilation holes 4 are arranged on both sides of the fume hood 1, and electric valves 5 are installed on the emergency ventilation holes 4;

[0047] Sealing brush strips 6 are installed in the gap between the front and rear end faces of the fume hood 1 and the bed surface of the sintered material layer 10; 8 ...

Embodiment 2

[0057] Adopt the device described in embodiment 1, cover fume cover 1 on the sintering machine, carry out sintering, concrete operation process is as follows:

[0058] Open the circulating flue gas inlet pipe 2, feed the circulating flue gas, and monitor the pressure gauge 12 and the oxygen level gauge 13 online to ensure that the pressure in the hot air hood 1 is negative and the oxygen concentration is 20%. move forward;

[0059] If the pressure of the pressure gauge 12 turns to a positive value, close the shut-off valve 3 of the circulating flue gas inlet pipe 2, open the electric valve 5 on the corresponding emergency vent hole 4, and enable the normal sintering mode; if the pressure of the pressure gauge 12 is normal, the oxygen level concentration is 15%, open the electric valve 5 on the corresponding emergency ventilation hole 4, add air, and continue hot blast sintering.

[0060] The sealed hot air cover device ensures that the oxygen concentration in the hot air cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com