Intelligent high-speed sizing machine

A sizing machine and intelligent technology, applied in the field of intelligent high-speed sizing machines, can solve problems such as poor yarn sizing ability, achieve the effect of improving warp weaving performance and ensuring sizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

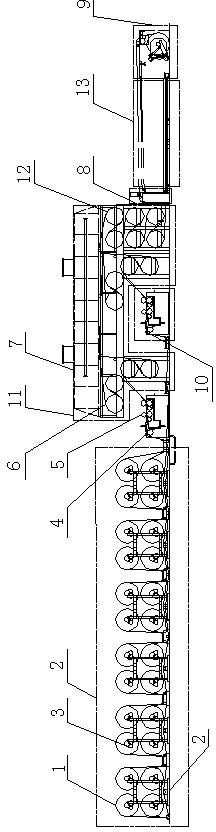

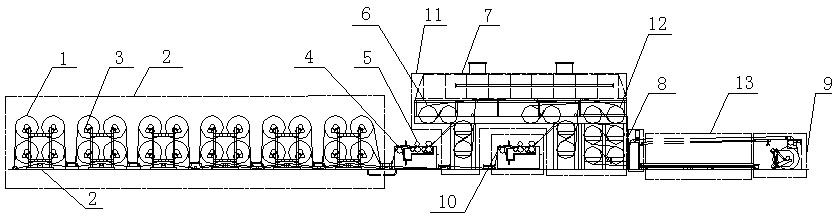

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, an intelligent high-speed sizing machine, including six parts of the warp creel 2, the size tank 10, the drying room 11, the URM device 8, the skeining area 13 and the machine head 9. The moving direction of the line is provided with a warp creel 2, a guide roller 4, a size tank 10, a drying room 11, a URM device 8, a splitting area 13 and a machine head 9 in sequence, and the warp creel 2 is provided with a pan head 1 And the support plate assembly 3, the size groove 10 is connected with the guide roller 4, the guide roller 4 is connected with the pressure roller 5, the drying room 11 is connected with the URM device 8, and the URM device 8 is connected with the twisting area 13, the splitting area 13 is connected to the machine head 9, the drying room 11 is provided with a pre-drying barrel 6 and a main drying barrel 12, and a fume hood is arranged above the pre-drying barrel 6 and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com